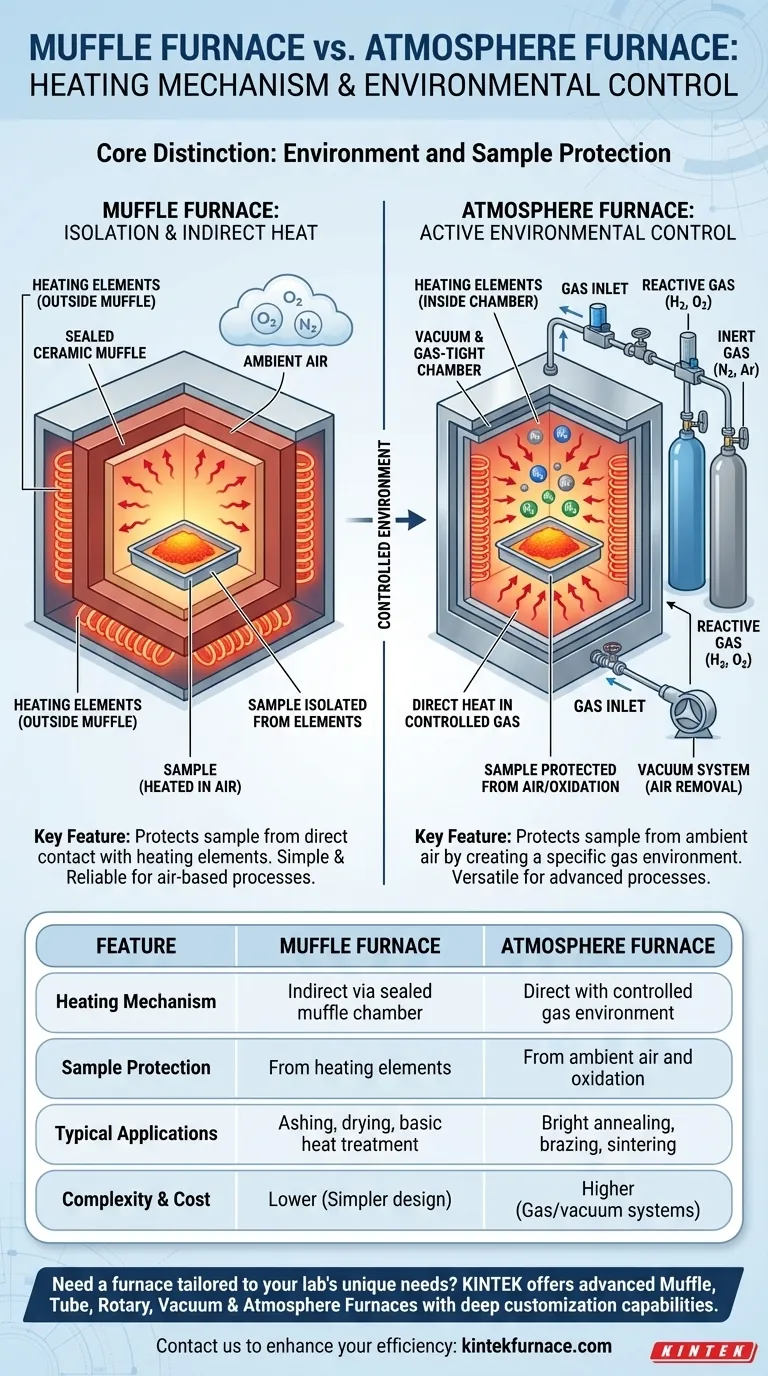

At a fundamental level, the primary difference between a muffle furnace and an atmosphere furnace is not the method of generating heat, but rather the environment in which that heat is applied to a sample. A muffle furnace heats a sample within a sealed chamber that is isolated from the heating elements, whereas an atmosphere furnace is specifically designed to control the gas composition surrounding the sample during heating.

The core distinction is about protection. A muffle furnace protects the sample from direct contact with the heating elements. An atmosphere furnace goes a step further, protecting the sample from the ambient air by replacing it with a controlled gas environment.

The Muffle Furnace: Isolation and Indirect Heat

A standard muffle furnace is the workhorse for general-purpose, high-temperature heating in air. Its design is defined by a key component: the muffle.

What is a "Muffle"?

The muffle is a sealed chamber, typically made of high-purity ceramic, that contains the sample being heated. It acts as a box-within-a-box.

The primary function of this chamber is to create a clean heating zone, isolated from the furnace's heating elements.

The Indirect Heating Mechanism

In a muffle furnace, heating elements (such as resistance wire coils) are located on the outside of the muffle chamber.

These elements heat the muffle itself, which then radiates uniform, indirect heat onto the sample inside. This prevents any particles from the heating elements from contaminating the sample.

The Atmosphere Furnace: Active Environmental Control

An atmosphere furnace is required when the chemical environment during heating is as critical as the temperature itself. Its design adds a layer of gas management technology.

Beyond Simple Heating

Many materials will react with oxygen in the air at high temperatures, a process called oxidation, which is often undesirable.

Atmosphere furnaces solve this by enabling processes in inert (non-reactive) or reactive gas environments.

System Design for Gas Control

These furnaces incorporate a gas path and vacuum system. This allows an operator to first remove the ambient air from the chamber and then introduce a specific process gas.

Common atmospheres include nitrogen or argon for inert processing, hydrogen for a reducing environment, or controlled levels of oxygen for specific oxidation studies.

Understanding the Trade-offs

Choosing between these two furnace types involves balancing process requirements against system complexity and cost.

Muffle Furnace: Simplicity and Reliability

A muffle furnace is mechanically simpler. With no need for vacuum pumps, gas plumbing, or flow controllers, it is generally more affordable, robust, and easier to operate and maintain.

Its primary limitation is that the environment inside the muffle is simply air. This makes it unsuitable for processes sensitive to oxygen.

Atmosphere Furnace: Process Versatility

The key advantage of an atmosphere furnace is its precise control over the chemical environment, which unlocks a wide range of advanced applications.

Processes like bright annealing (to prevent discoloration), brazing, and sintering of sensitive metals or ceramics are only possible in a controlled atmosphere.

Atmosphere Furnace: Complexity and Cost

This versatility comes with increased complexity. The addition of gas and vacuum systems raises the initial cost, requires more operator training, and introduces additional safety protocols, especially when using flammable gases like hydrogen.

Making the Right Choice for Your Application

Your decision depends entirely on whether your material or process is sensitive to the ambient air at your target temperature.

- If your primary focus is simple heat treatment in air: A muffle furnace is the most direct, reliable, and cost-effective solution for applications like ashing, drying, or basic materials testing.

- If your primary focus is preventing oxidation or inducing a specific gas-phase reaction: An atmosphere furnace is essential, as you must be able to precisely control the gaseous environment around your sample.

Choosing the right furnace begins with understanding that a muffle furnace protects your sample from the furnace, while an atmosphere furnace protects your sample from the air itself.

Summary Table:

| Feature | Muffle Furnace | Atmosphere Furnace |

|---|---|---|

| Heating Mechanism | Indirect via sealed muffle chamber | Direct with controlled gas environment |

| Sample Protection | From heating elements | From ambient air and oxidation |

| Typical Applications | Ashing, drying, basic heat treatment | Bright annealing, brazing, sintering |

| Complexity & Cost | Lower | Higher |

Need a furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your experimental requirements. Contact us today to enhance your efficiency and achieve superior results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?