In essence, a box type annealing atmosphere furnace is a specialized piece of industrial heating equipment designed for heat-treating materials within a precisely controlled gaseous environment. Unlike a standard furnace that operates in ambient air, this equipment allows you to introduce specific gases to prevent oxidation and other unwanted chemical reactions on the material's surface during the heating and cooling cycles.

The critical function of an atmosphere furnace is not just to heat a material, but to fundamentally protect and alter its surface chemistry. By replacing reactive air with an inert or reactive gas, it enables processes that are impossible to achieve in a standard furnace.

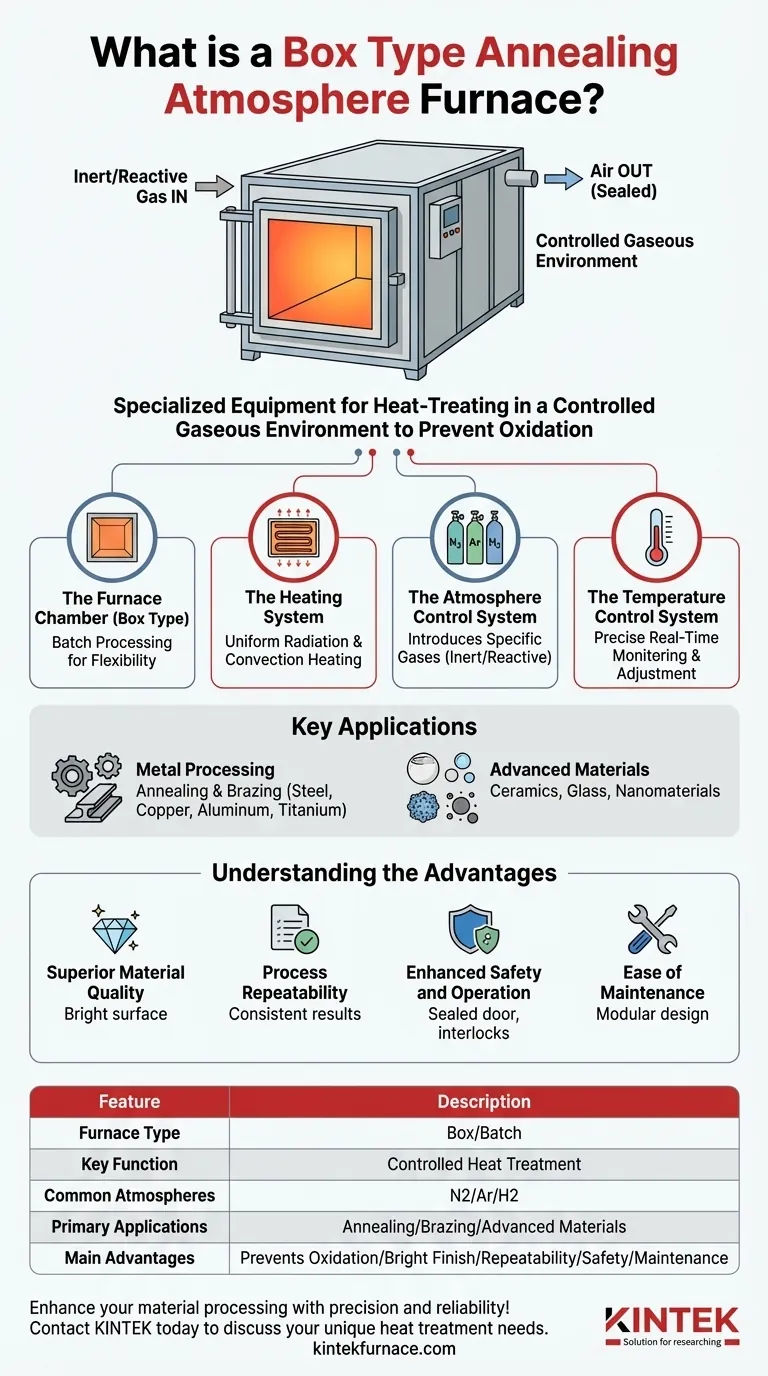

How It Works: The Core Components

To understand its value, it's best to break the furnace down into its key functional systems. Each part works in concert to deliver a highly controlled processing environment.

The Furnace Chamber (Box Type)

The term "box type" refers to its physical design: a single chamber with a door for loading and unloading materials. This configuration is ideal for processing parts in batches, offering flexibility for various sizes and shapes.

The Heating System

Heating elements are strategically placed within the furnace—often on the sides, top, or bottom. This arrangement uses both radiation and convection to transfer heat, ensuring a highly uniform temperature distribution throughout the chamber and across the workpiece.

The Atmosphere Control System

This is the defining feature. The system allows for the introduction of specific gases into the sealed furnace chamber. Common atmospheres include inert gases like nitrogen or argon to prevent oxidation, or reactive gases like hydrogen to actively clean or reduce surface oxides.

The Temperature Control System

A sophisticated control system uses temperature sensors (thermocouples) to monitor the internal temperature in real time. It automatically adjusts the power to the heating elements, precisely maintaining the temperature profile required for the specific annealing process.

Key Applications: Where This Furnace Excels

The ability to control both temperature and atmosphere makes this furnace indispensable across several high-value industries.

Metal Processing (Annealing & Brazing)

This is the most common application. It is used for the annealing, stress-relieving, and brazing of metals like steel, copper alloys, aluminum alloys, stainless steel, and titanium alloys. The controlled atmosphere is critical for achieving a bright, clean surface finish free of scale or discoloration.

Advanced Materials & Manufacturing

The furnace is also vital in producing and researching new materials. This includes processing ceramics, glass, nanomaterials, and composite materials where atmospheric purity is paramount to achieving the desired final properties.

Understanding the Advantages

Choosing an atmosphere furnace over a standard one comes down to a few key advantages that directly impact material quality and process reliability.

Superior Material Quality

By preventing oxidation, the furnace produces parts with a clean, "bright annealed" finish. This often eliminates the need for costly and time-consuming secondary cleaning processes like acid pickling or sandblasting.

Process Repeatability

Precise digital control over both temperature and gas flow ensures that every batch is processed under identical conditions. This leads to highly consistent and repeatable material properties, which is critical for quality assurance.

Enhanced Safety and Operation

Modern units are built with multiple safety interlocks, including over-temperature, over-current, and leakage protection. A reliably sealed furnace door is essential to prevent gas from leaking out and air from leaking in, ensuring both operator safety and process integrity.

Ease of Maintenance

Many contemporary designs are modular, allowing for easier access to components like heating elements and sensors. This simplifies maintenance and troubleshooting, reducing equipment downtime.

Making the Right Choice for Your Process

Use these points to determine if a box type atmosphere furnace aligns with your specific manufacturing or research goals.

- If your primary focus is preventing oxidation and achieving a clean surface finish: A box type atmosphere furnace is the correct tool, as it is specifically designed to protect materials from air during heat treatment.

- If your primary focus is high-volume, continuous production of uniform parts: You may want to consider a continuous furnace (like a conveyor or roller hearth furnace) with atmosphere control instead of a batch-style box furnace.

- If your primary focus is general heat treatment where surface oxidation is not a concern: A standard box furnace without atmosphere control is a simpler and more cost-effective solution.

Ultimately, selecting the right furnace is about matching the equipment's capabilities to your material and quality requirements.

Summary Table:

| Feature | Description |

|---|---|

| Furnace Type | Box type, batch processing chamber |

| Key Function | Heat treatment in controlled gaseous environments |

| Common Atmospheres | Inert gases (e.g., nitrogen, argon), reactive gases (e.g., hydrogen) |

| Primary Applications | Annealing, brazing of metals (steel, copper, aluminum, stainless steel, titanium); processing ceramics, glass, nanomaterials |

| Main Advantages | Prevents oxidation, ensures bright annealed finish, high process repeatability, enhanced safety, easy maintenance |

Enhance your material processing with precision and reliability! At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in metal processing or advanced materials research, our box type annealing atmosphere furnaces deliver superior quality, repeatability, and safety. Contact us today to discuss how we can optimize your heat treatment processes and drive your success!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity