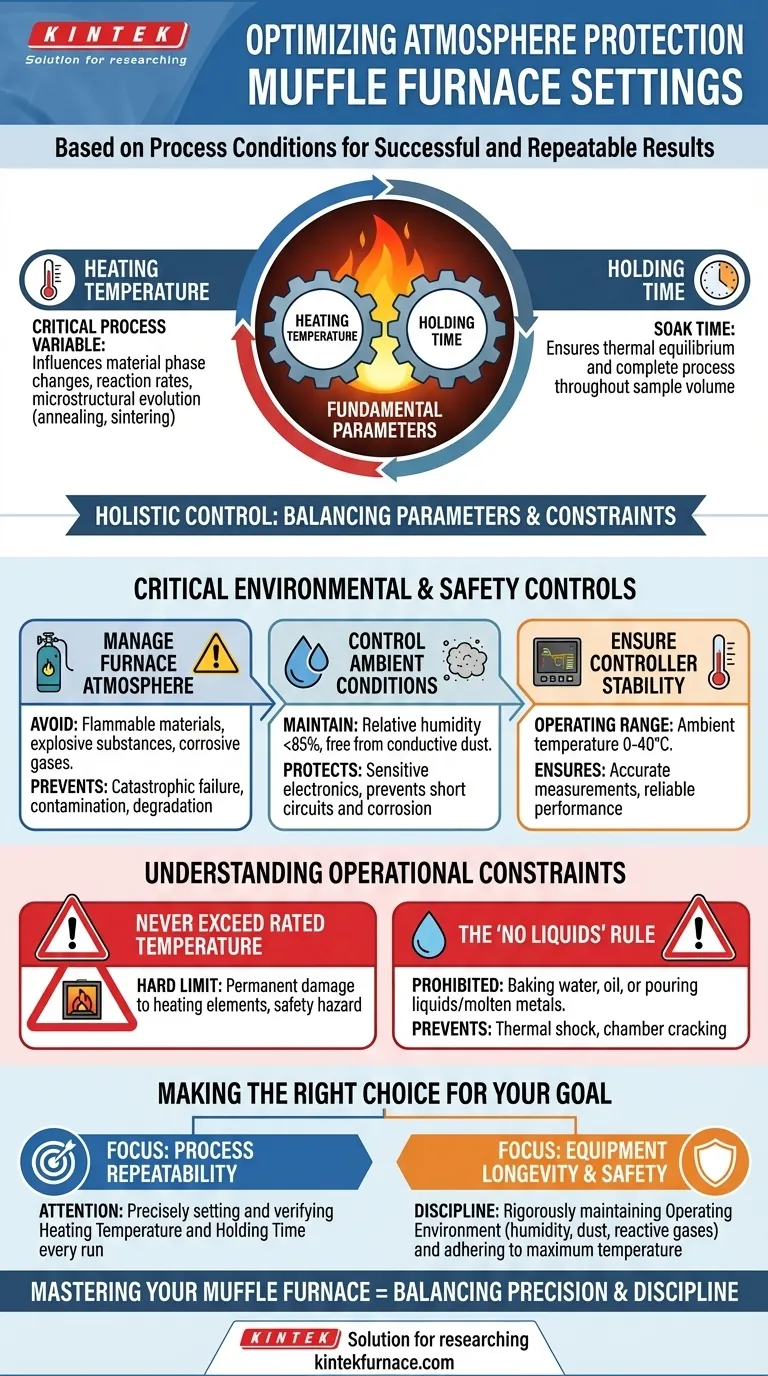

For any given process, the two fundamental parameters you must adjust in an atmosphere protection muffle furnace are the heating temperature and the holding time. These settings are dictated entirely by the specific requirements of the material or reaction you are working with. However, achieving successful and repeatable results goes beyond just these two settings.

The core challenge is not merely adjusting furnace settings, but maintaining a holistic, controlled system. True process control balances the adjustable parameters of temperature and time against the non-negotiable constraints of the operating environment and material handling protocols.

The Core Process Parameters

To achieve a desired material outcome, you must precisely control the energy delivered to your sample over a specific duration. This is managed through two primary settings.

Adjusting Heating Temperature

The temperature you set is the most critical process variable. It directly influences material phase changes, reaction rates, and microstructural evolution, such as in annealing or sintering processes. This value is determined by the scientific or industrial requirements of your specific task.

Setting the Holding Time

Holding time, or "soak time," is the duration the furnace maintains the setpoint temperature. This ensures that the entire sample reaches thermal equilibrium and that the desired physical or chemical process has sufficient time to complete throughout the material's volume.

Critical Environmental and Safety Controls

An atmosphere protection furnace is only as effective as the environment in which it operates. Ignoring these conditions compromises both the process integrity and the equipment itself.

Managing the Furnace Atmosphere

The workspace must be meticulously kept free of flammable materials, explosive substances, and corrosive gases. The presence of these agents can lead to catastrophic failure, sample contamination, or rapid degradation of the furnace chamber and heating elements.

Controlling Ambient Conditions

The furnace and its controller must operate in an environment with a relative humidity below 85% and free from conductive dust. High humidity and dust can damage sensitive electronics, cause short circuits, and lead to corrosion.

Ensuring Controller Stability

The electronic controller itself has a required operating environment. It must be kept within an ambient temperature range of 0-40°C to ensure its measurements are accurate and its performance is reliable. An overheated or frozen controller can lead to process failure.

Understanding the Operational Constraints

Certain rules are not flexible parameters but firm limitations designed to protect the equipment and ensure safety.

The Risk of Exceeding Rated Temperature

You must never exceed the furnace's rated temperature. Doing so will cause permanent damage to the heating elements, shorten the operational life of the furnace, and create a significant safety hazard. This is a hard limit, not a guideline.

The "No Liquids" Rule

Liquid samples, including water or oil, must not be baked in the furnace. Furthermore, do not pour any liquids or molten metals directly into the furnace chamber. This prevents thermal shock that can crack the ceramic muffle and maintains the cleanliness and integrity of the interior.

The Impact of an Uncontrolled Environment

Operating outside the specified environmental conditions (humidity, dust, corrosive gases) will inevitably lead to equipment malfunction, inaccurate temperature control, and a shortened lifespan for the entire system.

Making the Right Choice for Your Goal

Your operational focus will shift depending on your immediate priority.

- If your primary focus is process repeatability: Your attention must be on precisely setting and verifying the heating temperature and holding time for every run.

- If your primary focus is equipment longevity and safety: Your discipline must be in rigorously maintaining the operating environment—controlling for humidity, dust, and reactive gases while strictly adhering to the maximum rated temperature.

Ultimately, mastering your muffle furnace is an act of balancing the precision of your process settings with the discipline of your operational environment.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Heating Temperature | Dictates material phase changes and reaction rates; must not exceed furnace's rated limit. |

| Holding Time | Ensures thermal equilibrium and process completion; critical for repeatability. |

| Atmosphere Control | Avoid flammable, explosive, or corrosive substances to prevent contamination and damage. |

| Ambient Conditions | Maintain humidity <85%, no conductive dust, and controller temperature 0-40°C for reliability. |

| Operational Constraints | Never exceed rated temperature or introduce liquids to prevent thermal shock and hazards. |

Optimize your laboratory processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our strong deep customization capability ensures precise alignment with your experimental requirements, enhancing efficiency and safety. Contact us today to discuss how we can support your goals with reliable, high-performance equipment!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage