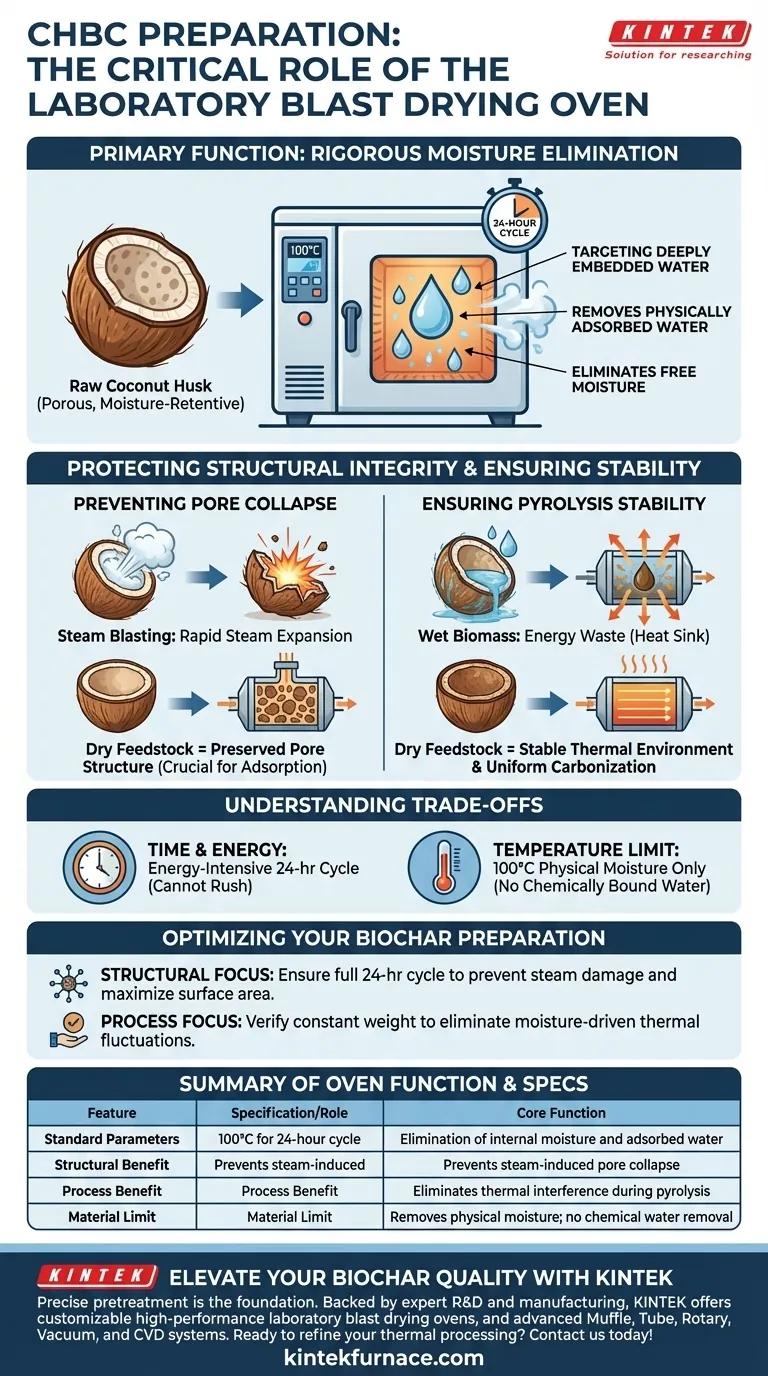

The primary function of a laboratory blast drying oven in this context is the rigorous elimination of internal moisture. specifically for Coconut Husk Biochar (CHBC), the oven is set to 100°C for a continuous 24-hour cycle to remove physically adsorbed water and free moisture. This step is a prerequisite for stabilizing the material before it undergoes high-temperature pyrolysis.

By removing moisture prior to carbonization, the blast drying oven prevents the rapid expansion of steam that causes irregular pore collapse. This ensures the physical structure of the biochar remains intact and the subsequent pyrolysis process proceeds without thermal interference.

The Critical Role of Moisture Removal

Targeting Deeply Embedded Water

Coconut husks are porous and retain significant amounts of water. The blast drying oven does not just dry the surface; it removes physically adsorbed water and free moisture trapped within the internal structure.

Specific Parameters for CHBC

For coconut husk biochar specifically, the protocol requires a precise temperature of 100°C maintained for 24 hours. This specific duration and heat level ensure complete drying without initiating premature thermal degradation of the biomass.

Protecting Structural Integrity

Preventing Pore Collapse

The most significant risk during pyrolysis is the rapid phase change of water into steam. If moisture remains in the husk, high temperatures cause this water to expand explosively within the material.

Avoiding "Steam Blasting"

This rapid release of steam can rupture the biochar's internal walls. By drying the material first, you prevent this irregular collapse, preserving the biochar pore structure required for high-quality adsorption applications.

Ensuring Pyrolysis Stability

Eliminating Thermal Interference

Moisture acts as a heat sink. If wet biomass enters the pyrolysis reactor, energy is wasted evaporating water rather than carbonizing the material.

Stabilizing the Reaction

Removing moisture eliminates its influence on the high-temperature pyrolysis process. This allows for a stable thermal environment and ensures the chemical changes occur uniformly throughout the batch.

Understanding the Trade-offs

Time and Energy Consumption

The 24-hour continuous drying cycle is energy-intensive and creates a bottleneck in production speed. You cannot rush this process; shortening the time poses a risk of incomplete drying.

Temperature Precision Limits

While effective for moisture, a standard blast drying oven operating at 100°C cannot remove chemically bound water (crystalline water). It is strictly limited to physical moisture removal; higher temperatures required for chemical dehydration would risk altering the feedstock's properties before pyrolysis begins.

Optimizing Your Biochar Preparation

To ensure consistent results, align your drying protocol with your specific research or production goals.

- If your primary focus is Structural Integrity: Ensure the full 24-hour cycle is completed to prevent steam-induced pore collapse and maximize surface area.

- If your primary focus is Process Stability: Verify the sample reaches constant weight to eliminate moisture-driven temperature fluctuations during pyrolysis.

This pretreatment step is the foundation of quality control, converting variable raw biomass into a consistent feedstock ready for carbonization.

Summary Table:

| Feature | Specification/Role in CHBC Preparation |

|---|---|

| Core Function | Elimination of internal moisture and physically adsorbed water |

| Standard Parameters | 100°C for a continuous 24-hour cycle |

| Structural Benefit | Prevents steam-induced pore collapse (maintains surface area) |

| Process Benefit | Eliminates thermal interference and energy waste during pyrolysis |

| Material Limit | Removes physical moisture; does not remove chemically bound water |

Elevate Your Biochar Quality with KINTEK

Precise pretreatment is the foundation of high-performance biochar. Backed by expert R&D and manufacturing, KINTEK offers high-performance laboratory blast drying ovens, and advanced Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to your unique research needs. Whether you are optimizing pore structure or scaling up carbonization, our equipment ensures the thermal stability and precision your lab demands.

Ready to refine your thermal processing? Contact us today to find the perfect solution!

Visual Guide

References

- Adil Ahmed, Perumal Asaithambi. Valorization of coconut husk into biochar for lead (Pb <sup>2+</sup> ) adsorption. DOI: 10.1515/gps-2024-0230

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Muffle Oven Furnace for Laboratory

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is Magnesium Hydride (MgH2) preferred for SiOx pre-magnesiation? Optimize Thermal Control and Battery Stability

- What is the function of rapid quenching after high-temperature heat treatment? Master AlSi10Mg Microstructural Control

- What are the temperature advantages of using Cathodic Arc Deposition (CAD)? Boost Film Hardness at Lower Temperatures

- Why is an automatically controlled mesh belt quenching line used for bearing rings? Precision & Stability Explained

- What is the function of wet ball milling in the synthesis of SPAN? Optimize Your Sulfur Content Through Deep Mixing

- Why is annealing in a heat treatment furnace performed on graphite flake/copper composite samples before performance testing? Ensure Data Integrity for Precision Thermal Expansion Measurements

- What are the benefits of ESR for carbonitride distribution in H13 steel? Enhance Your Material's Isotropic Properties

- What is the significance of a laboratory vacuum drying oven in the treatment of hybrid membranes? | Optimize Performance