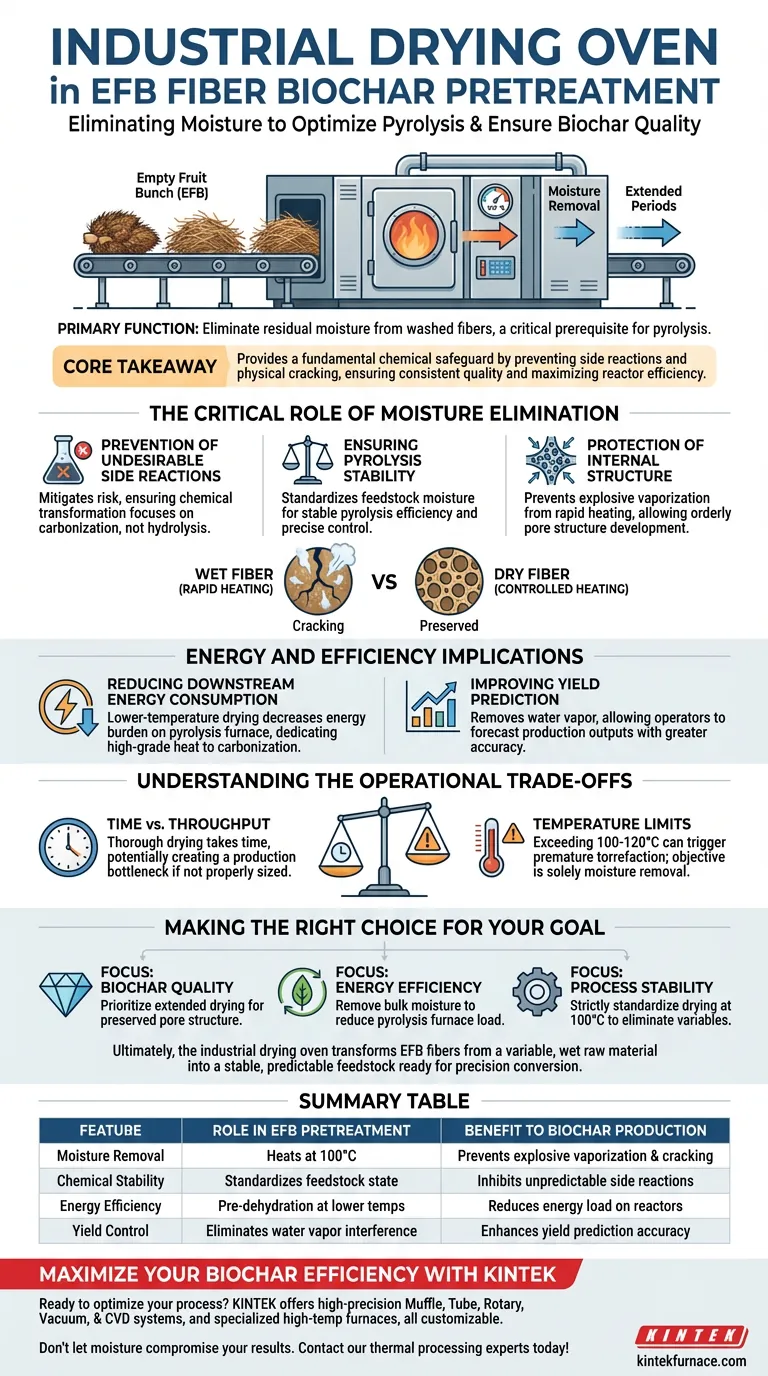

The primary function of an industrial drying oven in the pretreatment of Empty Fruit Bunch (EFB) fibers is to eliminate residual moisture from washed fibers, typically by heating them at 100 °C for extended periods. This step is a critical prerequisite to the pyrolysis process, serving to stabilize the chemical environment and prevent structural damage to the biomass before it enters high-temperature reactors.

Core Takeaway While its operation is simple, the drying oven provides a fundamental chemical safeguard. By removing moisture prior to pyrolysis, it prevents disruptive side reactions and physical cracking caused by rapid vaporization, thereby ensuring consistent biochar quality and maximizing reactor efficiency.

The Critical Role of Moisture Elimination

Prevention of Undesirable Side Reactions

The presence of water during the high-temperature breakdown of biomass is not chemically neutral.

If moisture remains in the EFB fibers during pyrolysis, it can trigger unpredictable side reactions. The drying oven mitigates this risk, ensuring that the chemical transformation remains focused on carbonization rather than hydrolysis or other moisture-driven variances.

Ensuring Pyrolysis Stability

Consistency is vital for industrial biochar production.

By standardizing the moisture content of the feedstock, the drying process ensures stable pyrolysis efficiency. This stabilization provides a reliable foundation for the precise control of chemical stoichiometry in the subsequent stages.

Protection of Internal Structure

Rapid heating of wet biomass can be destructive.

If fibers containing significant moisture are subjected immediately to high pyrolysis temperatures, the water vaporizes explosively. This rapid expansion can cause material cracking, whereas pre-drying allows for the orderly development of the biochar's internal pore structure.

Energy and Efficiency Implications

Reducing Downstream Energy Consumption

Removing water in a lower-temperature oven is generally more energy-efficient than boiling it off in a high-temperature reactor.

Lowering the moisture content during pretreatment significantly decreases the energy burden on the pyrolysis furnace. This allows the high-grade heat of the furnace to be dedicated to carbonization rather than water evaporation.

Improving Yield Prediction

Water vapor introduces variables that complicate process modeling.

By effectively removing moisture, the drying oven prevents water vapor from interfering with biochar yield prediction models. This allows operators to forecast production outputs with greater accuracy.

Understanding the Operational Trade-offs

The Balance of Time vs. Throughput

Drying EFB fibers is not an instantaneous process; it requires "extended periods" at 100 °C.

This creates a potential bottleneck in the production line. While thorough drying is essential for quality, it requires significant residence time, which can limit the overall throughput speed of the facility if not properly sized.

Temperature Limits

The drying temperature must be carefully controlled.

While the goal is dehydration, exceeding the target temperature (e.g., going well above 100–120 °C) during this stage can inadvertently trigger premature torrefaction or thermal degradation. The objective is strictly moisture removal, not the alteration of the carbon structure itself.

Making the Right Choice for Your Goal

To optimize your biochar production line, consider how the drying stage aligns with your specific objectives:

- If your primary focus is Biochar Quality: Prioritize extended drying times to ensure near-zero moisture, which preserves pore structure and prevents physical cracking.

- If your primary focus is Energy Efficiency: Utilize the drying oven to remove the bulk of moisture, as this reduces the heavy fuel load required by the high-temperature pyrolysis furnace.

- If your primary focus is Process Stability: Ensure your drying protocol is strictly standardized at 100 °C to eliminate variables that lead to unpredictable side reactions.

Ultimately, the industrial drying oven transforms EFB fibers from a variable, wet raw material into a stable, predictable feedstock ready for precision conversion.

Summary Table:

| Feature | Role in EFB Pretreatment | Benefit to Biochar Production |

|---|---|---|

| Moisture Removal | Heats fibers at 100°C to eliminate water | Prevents explosive vaporization and physical cracking |

| Chemical Stability | Standardizes feedstock state | Inhibits unpredictable side reactions like hydrolysis |

| Energy Efficiency | Pre-dehydration at lower temperatures | Reduces the energy load on high-temperature pyrolysis reactors |

| Yield Control | Eliminates water vapor interference | Enhances the accuracy of production yield prediction models |

Maximize Your Biochar Efficiency with KINTEK

Ready to optimize your biomass conversion process? Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique EFB processing needs.

Don't let moisture compromise your results. Contact our thermal processing experts today to find the perfect industrial drying and pyrolysis solution for your facility!

Visual Guide

References

- Fairuz Gianirfan Nugroho, Abu Talha Aqueel Ahmed. Utilizing Indonesian Empty Palm Fruit Bunches: Biochar Synthesis via Temperatures Dependent Pyrolysis. DOI: 10.3390/nano15010050

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the function of a ball mill in the raw material pretreatment stage for the szaibelyite vacuum thermal reduction process?

- What is the primary role of high-purity hydrogen in heat treatment? Achieve Superior Metallic Coating Protection

- What are the core technical advantages of a flash sintering system? Elevate KNN Ceramic Manufacturing Performance

- What are the advantages of the Laser Hearth Method for Zirconia? Achieve High Purity & Density for Advanced Research

- What is the necessity of in-situ DRIFTS in formaldehyde oxidation? Uncover Real-Time Catalytic Reaction Mechanisms

- What is the technical value of a Hydrogen Reduction-type Test Furnace in green steelmaking? Scale Sustainable Production

- How does the electric arc furnace contribute to carbon neutrality? Decarbonizing Steel with EAF Technology

- Why are Cu2O and Ga2O3 targets preferred for CuGaO2 films? Achieving Precision in Delafossite Sputtering