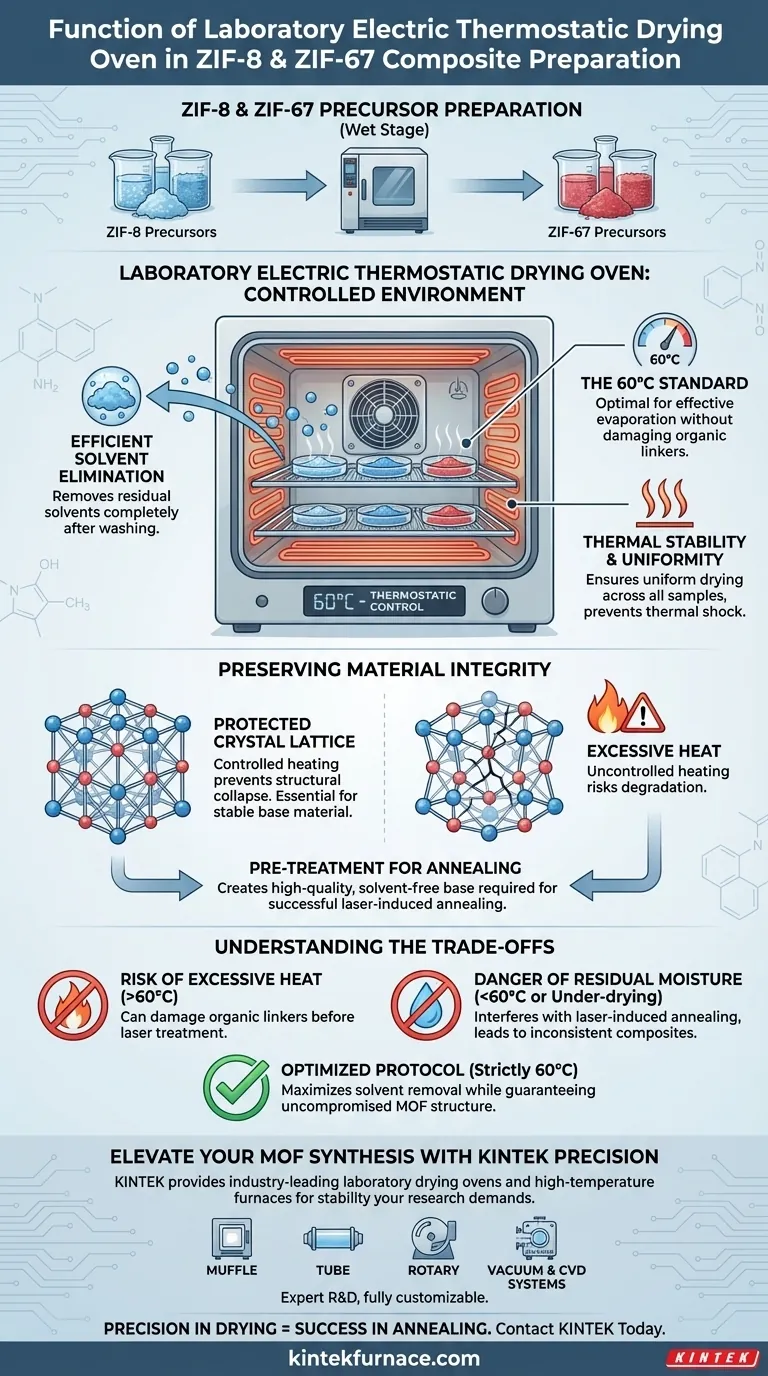

The primary function of a laboratory electric thermostatic drying oven in this context is to provide a controlled environment for the complete removal of residual solvents from ZIF-8 and ZIF-67 precursors. By maintaining a stable, low-to-medium temperature—typically set at 60°C—it ensures the material is thoroughly dried following the washing stage without compromising its structural properties.

Core Takeaway The drying process is a critical quality control step, not just a method of evaporation. By utilizing a thermostatic oven, you ensure the integrity of the Metal-Organic Framework (MOF) crystal structure is preserved, creating the necessary high-quality base material required for successful laser-induced annealing.

The Critical Role of Controlled Heating

Efficient Solvent Elimination

After the initial synthesis and washing of ZIF-8 and ZIF-67, residual solvents remain trapped within the material. The drying oven is employed specifically to drive off these solvents completely.

The 60°C Standard

The reference protocol typically designates 60°C as the optimal operating temperature. This specific setting provides enough thermal energy to evaporate solvents effective while remaining in the low-to-medium heat range.

Stability vs. Speed

Unlike rapid heating methods, a thermostatic oven ensures thermal stability. This consistency is vital for uniform drying across the entire sample batch.

Preserving Material Integrity

Protecting the Crystal Lattice

ZIF-8 and ZIF-67 are Metal-Organic Frameworks (MOFs) with distinct crystal structures. The oven’s controlled environment prevents the structural collapse or degradation that might occur with uncontrolled heating.

Preventing Thermal Shock

Sudden temperature fluctuations can induce stress in the material. The thermostatic function mitigates this risk, ensuring the crystals remain stable during the transition from wet precursor to dry powder.

Pre-Treatment for Annealing

The ultimate goal of this drying phase is to prepare the material for the next step: laser-induced annealing. Only a structurally sound, solvent-free base material will yield high-quality results in the subsequent laser processing.

Understanding the Trade-offs

The Risk of Excessive Heat

While higher temperatures might dry the sample faster, deviating significantly above 60°C carries risks. Excessive heat can damage the organic linkers within the ZIF structure before the material is even subjected to the laser.

The Danger of Residual Moisture

Conversely, under-drying or using temperatures too low leaves solvent residues. This impurity can interfere with the laser-induced annealing process, leading to inconsistent composite formation.

Optimizing Your Synthesis Protocol

To ensure the highest quality ZIF-8 and ZIF-67 composites, apply the following guidelines based on your specific objectives:

- If your primary focus is Crystal Quality: Strictly maintain the temperature at 60°C to maximize solvent removal while guaranteeing the MOF structure remains uncompromised.

- If your primary focus is Process Consistency: Use the thermostatic features to stabilize the environment before introducing samples, ensuring every batch starts with identical thermal conditions for the laser phase.

Precision in the drying phase is the foundation for success in the annealing phase.

Summary Table:

| Feature | Parameter/Function | Benefit to ZIF-8/ZIF-67 Preparation |

|---|---|---|

| Standard Temp | 60°C | Optimal solvent evaporation without organic linker damage. |

| Control Type | Thermostatic | Prevents thermal shock and ensures uniform batch drying. |

| Primary Goal | Solvent Removal | Eliminates impurities that interfere with laser-induced annealing. |

| Structural Impact | Crystal Preservation | Protects the Metal-Organic Framework lattice from collapse. |

Elevate Your MOF Synthesis with KINTEK Precision

High-quality ZIF-8 and ZIF-67 composites require the perfect thermal foundation. KINTEK provides industry-leading laboratory drying ovens and high-temperature furnace systems designed to deliver the stability your research demands.

Backed by expert R&D and manufacturing, we offer specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your unique material needs. Ensure your precursors are perfectly prepared for successful laser-induced annealing by partnering with thermal processing experts.

Contact KINTEK Today to Customize Your Laboratory Solution

Visual Guide

References

- Hengyi Guo, Andrew G. Thomas. Laser Synthesis of Platinum Single-Atom Catalysts for Hydrogen Evolution Reaction. DOI: 10.3390/nano15010078

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is rhenium selected as a material for sample capsules? Key Benefits for High-Temperature Experimental Success

- What factors influence the lifespan of alumina ceramic furnace tubes? Maximize Durability and Performance

- What are the main types of laboratory furnaces? Find Your Perfect High-Temperature Solution

- Why is a precision laboratory hydraulic press required for sulfide-based batteries? Achieve Critical Ion Conductivity

- Why is a Zirconia (ZrO2) oxygen sensor used for CaO-Al2O3-VOx slag research? Achieve Precise Redox Control

- How does an in-situ reaction chamber in HTXRD facilitate BiFeO3 synthesis study? Mapping Real-Time Phase Evolution

- Why is dimensional accuracy important for alumina ceramic furnace tubes? Ensure Reliable High-Temp Performance

- Why is a Pt5%Au crucible required for S53P4 bioactive glass? Ensure Purity at 1400°C