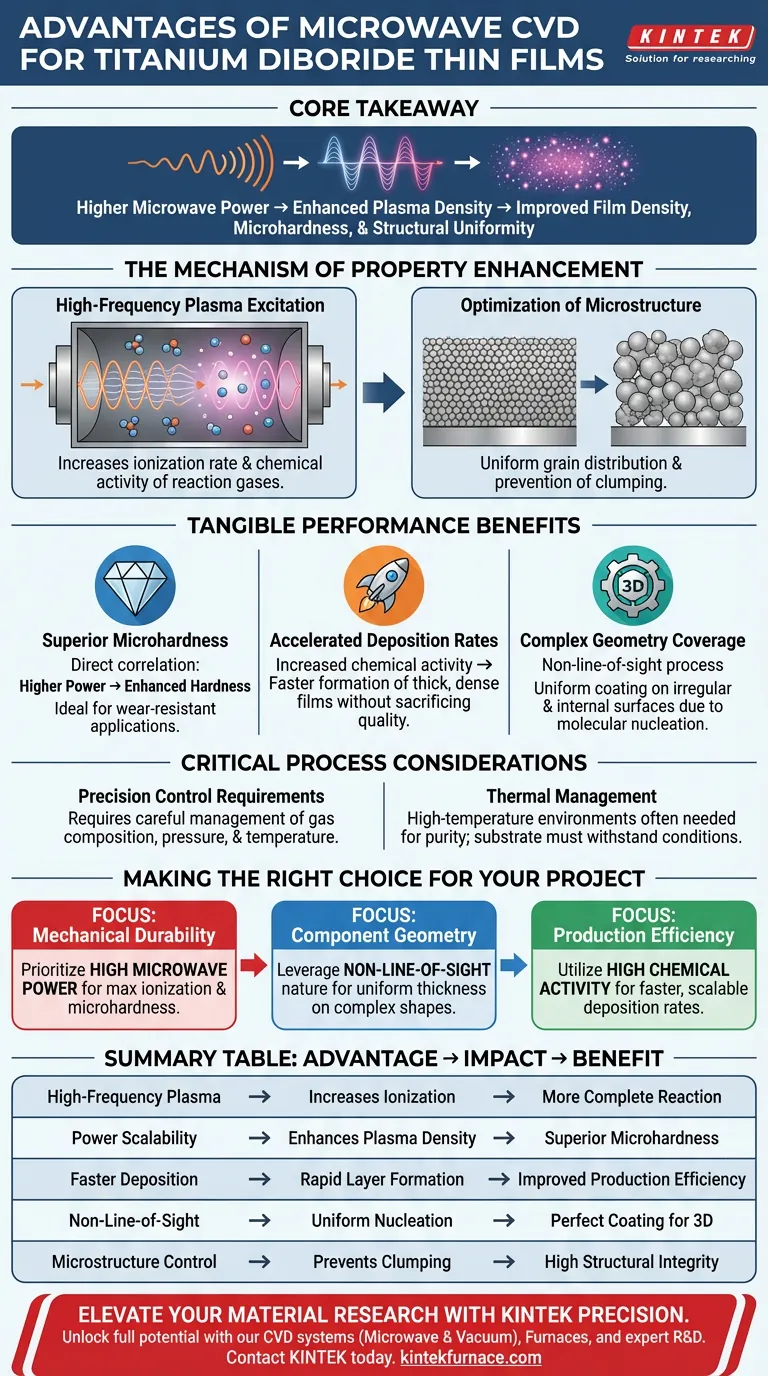

Microwave Chemical Vapor Deposition (CVD) provides a superior method for preparing Titanium Diboride thin films by fundamentally altering the energy state of the reaction. By utilizing high-frequency electromagnetic fields to excite plasma, the system significantly increases the ionization rate and chemical activity of the reaction gases. This high-energy environment directly results in films with improved microhardness, optimized grain distribution, and faster deposition rates compared to lower-energy methods.

Core Takeaway: The primary value of using Microwave CVD for Titanium Diboride lies in the relationship between microwave power and film density. Higher power levels enhance the plasma density, which not only accelerates the coating process but critically improves the mechanical hardness and structural uniformity of the final material.

The Mechanism of Property Enhancement

High-Frequency Plasma Excitation

The core advantage of this system is its use of high-frequency electromagnetic fields. This energy source excites the plasma within the chamber.

As the plasma excites, the ionization rate of the reaction gases increases dramatically. This heightened chemical activity ensures that the precursors react more completely and efficiently.

Optimization of Microstructure

For Titanium Diboride films, structural integrity is paramount. The Microwave CVD process facilitates a more uniform microstructure across the bulk material.

This uniformity is driven by improved grain distribution. The energetic deposition environment prevents the clumping or irregular growth often seen in less controlled methods.

Tangible Performance Benefits

Superior Microhardness

There is a direct correlation between the microwave power applied and the physical quality of the film. Increasing the power enhances the microhardness of the Titanium Diboride layer.

This makes the method particularly valuable for wear-resistant applications where the surface must withstand significant mechanical stress.

Accelerated Deposition Rates

Efficiency is a critical factor in film preparation. The increased chemical activity of the reaction gases leads to higher deposition rates.

This allows for the rapid formation of thick, dense films without sacrificing the quality or stability of the layer.

Complex Geometry Coverage

Like standard CVD, this method is a non-line-of-sight process. It allows for the coating of irregularly shaped substrates and internal surfaces.

Because the nucleation occurs at a molecular level, the film remains dense and uniform even on complex 3D structures.

Critical Process Considerations

Precision Control Requirements

While the system is powerful, achieving high-quality Titanium Diboride films requires precise management of process parameters.

Operators must carefully control gas composition, pressure, and temperature. Variations in these settings can alter the film's adhesion and purity.

Thermal Management

Although some CVD processes allow for lower temperatures, the decomposition and chemical reaction of reactants often require high-temperature environments to ensure high purity.

You must ensure your substrate can withstand the specific thermal conditions required to decompose the Titanium Diboride precursors effectively.

Making the Right Choice for Your Project

The decision to use Microwave CVD should be driven by your specific material performance requirements.

- If your primary focus is mechanical durability: Prioritize high microwave power settings to maximize ionization, which directly increases the microhardness of the Titanium Diboride film.

- If your primary focus is component geometry: Leverage the non-line-of-sight nature of the plasma gas to ensure uniform thickness on irregular or internal surfaces.

- If your primary focus is production efficiency: Utilize the system's high chemical activity to achieve faster deposition rates suitable for scalable manufacturing.

By calibrating the microwave power to the specific needs of the Titanium Diboride reaction, you transform a standard coating process into a precision engineering tool.

Summary Table:

| Advantage | Impact on Titanium Diboride Films | Benefit to Performance |

|---|---|---|

| High-Frequency Plasma | Increases gas ionization and chemical activity | More complete precursor reaction |

| Power Scalability | Directly enhances plasma density and film density | Superior microhardness and durability |

| Faster Deposition | Rapid formation of dense, thick layers | Improved production efficiency |

| Non-Line-of-Sight | Uniform molecular nucleation on all surfaces | Perfect coating for complex 3D geometries |

| Microstructure Control | Prevents clumping and ensures even grain growth | High structural integrity and stability |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of high-performance coatings with KINTEK. As experts in lab-scale and industrial high-temperature solutions, we provide cutting-edge CVD systems (including Microwave and Vacuum), Muffle, and Tube furnaces tailored to your exact specifications.

Whether you are developing ultra-hard Titanium Diboride thin films or exploring advanced semiconductor materials, our expert R&D and manufacturing teams ensure you have the precise control needed for success. Contact KINTEK today to discuss your unique project requirements and see how our customizable systems can accelerate your results.

Visual Guide

References

- Xinran Lv, Gang Yu. Review on the Development of Titanium Diboride Ceramics. DOI: 10.21926/rpm.2402009

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are the main classifications of CVD based on operating conditions? Choose the Right Process for Superior Film Quality

- What is the function of a radio frequency (RF) plasma sputtering system? Precision PtNP Underlayer Fabrication

- What are the different types of CVD furnaces? Choose the Right One for Your Lab

- What are the drawbacks of CVD coatings? Understand the limitations and trade-offs for your application.

- What is the function of Atomic Layer Deposition (ALD) equipment? Precision Engineering of Ni/BaZrO3/MAO Catalysts

- What industries commonly use CVD furnaces and for what purposes? Discover Precision Coating Solutions

- What is the working principle of Vapor Phase Aluminizing (VPA) equipment? Master High-Performance Thermal Coatings

- What factors contribute to variation in the CVD coating process? Master Consistency in Chemical Vapor Deposition