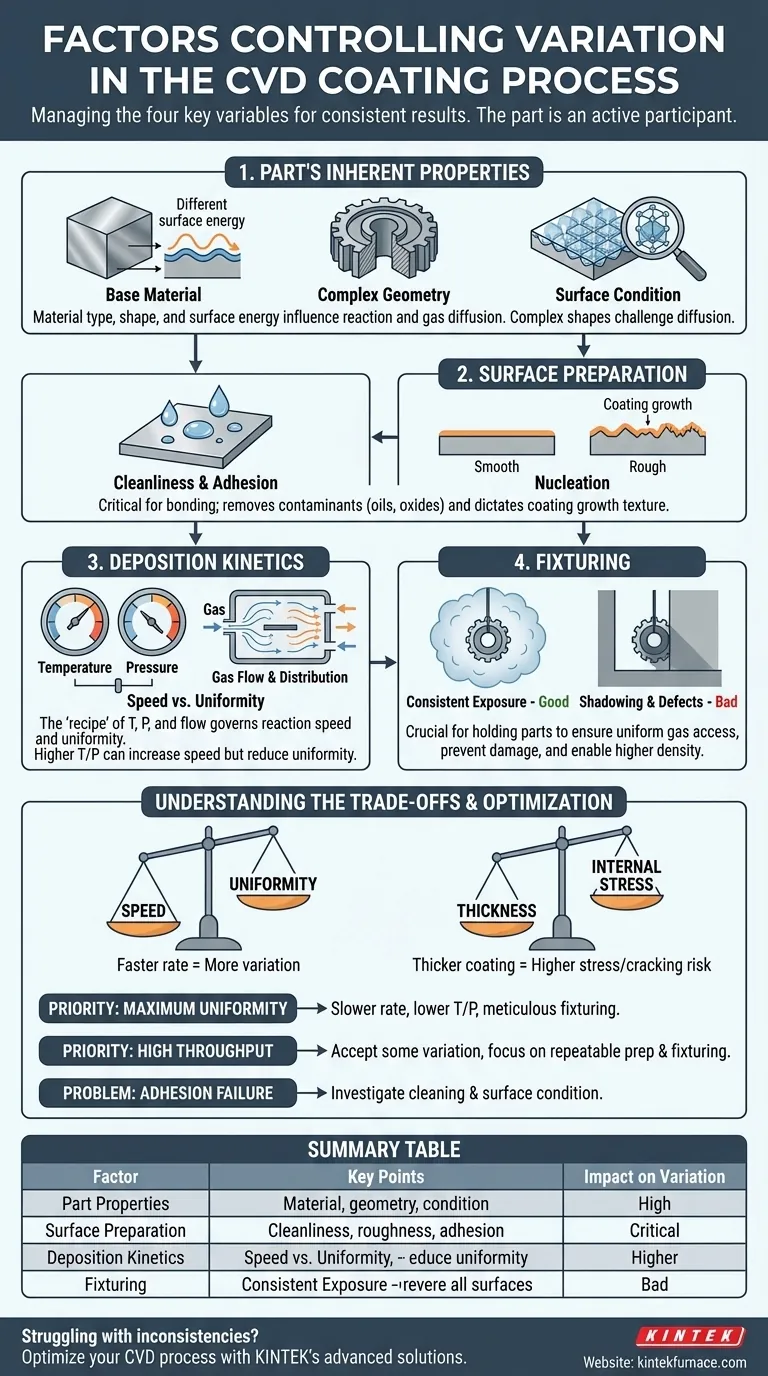

Ultimately, controlling variation in Chemical Vapor Deposition (CVD) is a matter of managing four key variables. The most significant factors are the inherent properties of the part being coated (its base material and physical shape), the condition of its surface prior to coating, the specific chemical kinetics of the reaction, and the physical setup within the reactor, including how the part is held. Inconsistent results almost always trace back to a lack of control over one or more of these domains.

The goal of a consistent CVD process is not to eliminate all variables, but to control them. Successful coating relies on understanding that the part itself is an active participant in a chemical reaction, where its material, geometry, and surface preparation dictate the final outcome just as much as the process parameters.

The Part's Inherent Properties: Material and Geometry

The components you intend to coat are not passive substrates. Their physical and material characteristics actively influence the final coating quality and uniformity.

Base Material and Surface Condition

The type of metal or alloy being coated has a direct impact on the reaction. Different materials possess different surface energies and may have catalytic effects that can accelerate or alter coating growth in localized areas.

For example, a standard 316 stainless steel will behave differently than an exotic alloy, potentially requiring adjustments to the process temperature or precursor gas concentration to achieve the same result.

The Challenge of Complex Geometries

Unlike line-of-sight processes like PVD, CVD precursor gases can coat complex internal and external surfaces. However, this is not without limits.

Confined areas, such as the deep bore of a needle or narrow channels, present a diffusion challenge. The reactant gases must physically travel into these spaces, and their concentration may become depleted, resulting in a thinner coating compared to more exposed surfaces.

The Critical Role of Surface Preparation

The condition of the part's surface immediately before it enters the reactor is arguably the most critical factor for ensuring coating adhesion and uniformity. The CVD process bonds the coating at an atomic level, and it cannot bond to contaminants.

Surface Cleanliness and Adhesion

Any contaminants—oils, oxides, dust, or residues from prior manufacturing steps—will prevent the chemical reaction from occurring properly, leading to poor adhesion or voids in the coating.

A rigorous, multi-stage cleaning and surface preparation protocol is non-negotiable for a repeatable CVD process.

How Surface Roughness Alters Coating Growth

The texture of the surface dictates how the coating nucleates and grows. A very rough surface has significantly more surface area than a smooth one.

This can lead to a mechanically interlocked but potentially uneven coating. An electropolished or finely machined surface provides a more uniform foundation, promoting even thickness and a more consistent finish.

Controlling the Deposition Kinetics

The "recipe" for the CVD process—temperature, pressure, and gas flow—governs the speed and nature of the chemical reaction.

The Temperature and Pressure Relationship

CVD is performed at elevated temperatures and typically under vacuum. These are the primary levers for controlling the reaction rate.

Higher temperatures generally lead to faster deposition, but if the reaction is too fast, the gas may be depleted before it reaches all surfaces of the part, reducing uniformity.

Precursor Gas Flow

The rate and distribution of the precursor gas into the chamber are crucial. If the flow is not managed correctly, parts closer to the gas inlet may receive a thicker coating than parts further away.

Proper reactor design and gas distribution systems are essential for ensuring all parts in a batch are exposed to a consistent concentration of reactants.

The Overlooked Factor: Fixturing

How a part is held within the reactor can introduce significant variation. Custom fixturing is a process control tool, not an afterthought.

Ensuring Consistent Exposure

Fixtures must hold parts securely while exposing all critical surfaces to the precursor gas flow. Any point where the fixture touches the part will not be coated.

Poorly designed fixtures can create "shadowing" effects or block gas flow to certain areas, leading to predictable inconsistencies from part to part.

Preventing Damage and Enhancing Efficiency

Good fixturing prevents parts from moving or touching during handling and coating, which prevents scratches or other surface defects. It also allows for higher part density in the reactor, improving throughput and efficiency without compromising quality.

Understanding the Trade-offs

Achieving a perfect coating is a balancing act. Understanding the inherent compromises is key to setting realistic expectations and optimizing for your primary goal.

Speed vs. Uniformity

The desire for a fast, low-cost process is often in direct conflict with the need for high uniformity. Faster reaction rates (driven by higher temperatures or pressures) can save time and money but almost always increase thickness variation, especially on complex parts.

Coating Thickness vs. Internal Stress

As a CVD coating gets thicker, internal stresses build within the film. If this stress exceeds the coating's adhesive or cohesive strength, it can lead to cracking, flaking, or delamination.

For every coating/substrate combination, there is a practical thickness limit that cannot be exceeded without compromising the film's integrity.

Material Compatibility and Masking

The high temperatures required for CVD limit the types of base materials that can be coated without being damaged or undergoing undesirable metallurgical changes. Furthermore, effectively masking specific areas to prevent coating is notoriously difficult in CVD, as the gas will penetrate any gap.

Making the Right Choice for Your Goal

To control variation, you must first define your priority. Use these guidelines to focus your process development and troubleshooting efforts.

- If your primary focus is maximum uniformity on complex parts: Prioritize a slower reaction rate with lower temperatures and meticulous fixturing to ensure even gas flow.

- If your primary focus is high throughput and cost-efficiency: Accept some thickness variation and focus on highly repeatable surface preparation and fixturing to keep that variation predictable.

- If you are experiencing adhesion failures: The first place to investigate is your pre-coating cleaning process and the surface condition of the base material.

- If you are coating a new material or geometry: Run test coupons to establish a baseline for how the material behaves and to map coating thickness across the part before committing to a full production run.

By treating the part, the surface, and the process as an interconnected system, you can move from managing variation to mastering consistency.

Summary Table:

| Factor | Key Points | Impact on Variation |

|---|---|---|

| Part Properties | Material type, geometry, surface condition | High; affects reaction and gas diffusion |

| Surface Preparation | Cleanliness, roughness, adhesion | Critical; ensures uniform coating and bonding |

| Deposition Kinetics | Temperature, pressure, gas flow | Moderate; controls reaction speed and uniformity |

| Fixturing | Part holding, gas exposure, shadowing | Significant; influences coating consistency and defects |

Struggling with CVD coating inconsistencies? At KINTEK, we specialize in advanced high-temperature furnace solutions, including CVD/PECVD Systems, to help you achieve precise and repeatable results. Our strong deep customization capability ensures we can tailor our products—like Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces—to your unique experimental needs. Don't let variation hold you back—contact us today to optimize your CVD process and boost your lab's efficiency!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition