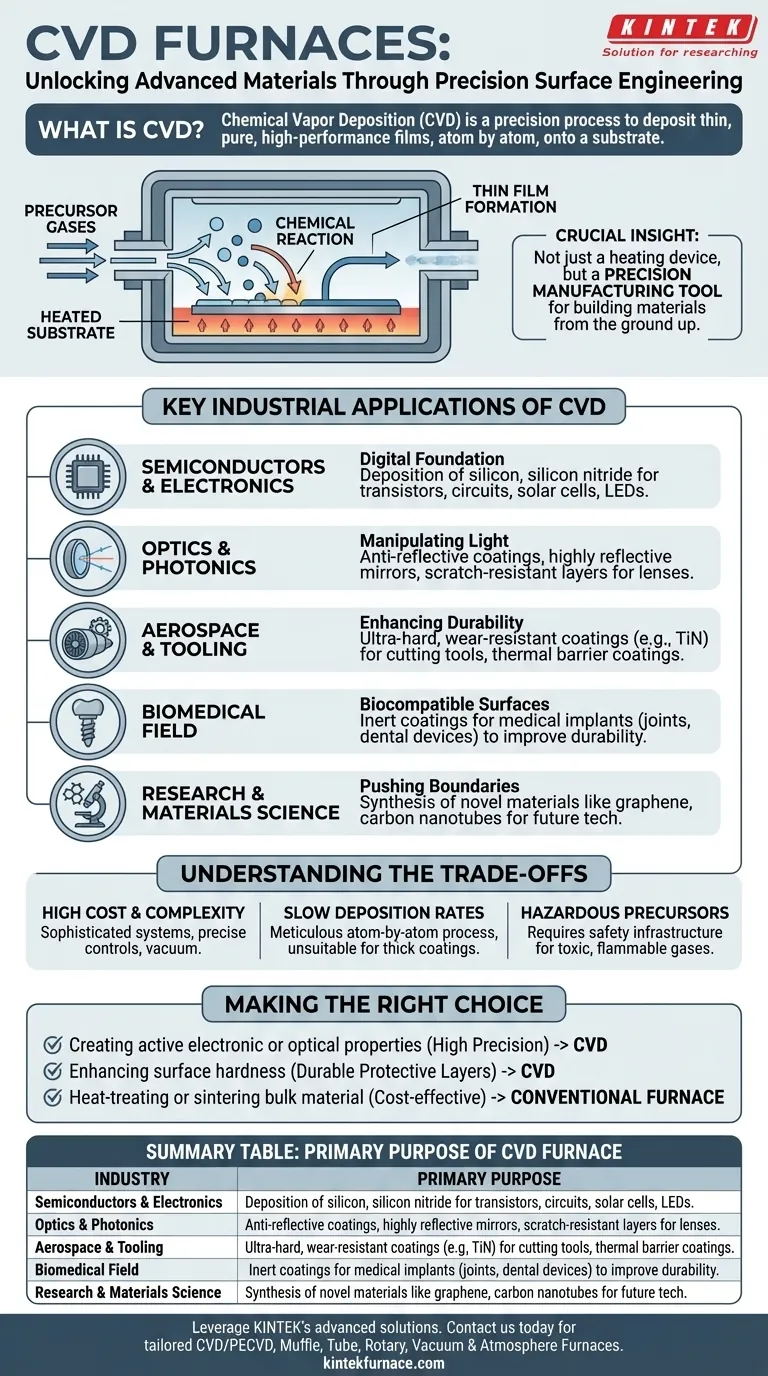

In short, Chemical Vapor Deposition (CVD) furnaces are primarily used in the semiconductor, optics, and aerospace industries. Their purpose is to deposit exceptionally thin, pure, and high-performance films of material onto a substrate, atom by atom, to create components with specific electronic, optical, or mechanical properties.

The crucial insight is that a CVD furnace is not just a heating device; it's a precision manufacturing tool. Industries turn to CVD when they need to build a material with a specific function from the ground up, creating coatings that are often impossible to produce by any other method.

The Core Principle: Why CVD is Different

A standard furnace simply heats a material to change its properties, such as for annealing or sintering. A CVD furnace, however, is a key part of a system that performs a more complex task: building a new, solid material directly onto a surface.

How Chemical Vapor Deposition Works

The process involves introducing reactive precursor gases into a heated chamber (the furnace). When these gases come into contact with the hot surface of a substrate, a chemical reaction occurs. This reaction causes a solid material to "deposit" or grow on the substrate, forming an extremely thin and uniform film.

Control at the Atomic Level

This method allows for incredible control over the film's thickness, purity, and structure. It is this atomic-level precision that makes CVD indispensable for creating high-technology components where material properties are paramount.

Key Industrial Applications of CVD

The ability to engineer surfaces with specific functions makes CVD technology a cornerstone of several advanced industries.

Semiconductors and Electronics: The Digital Foundation

This is the largest and most critical application. CVD is used to deposit the foundational layers of silicon, silicon nitride, and other materials that form transistors and circuits on a silicon wafer. It is also essential for producing thin films for solar cells (photovoltaics) and LEDs. Without CVD, modern microchips would not exist.

Optics and Photonics: Manipulating Light

Precise control over thickness and refractive index is vital in optics. CVD is used to apply anti-reflective coatings on lenses for cameras and eyeglasses, create highly reflective mirrors for lasers, and produce protective, scratch-resistant coatings for optical components.

Aerospace and Tooling: Enhancing Durability

In aerospace and high-performance automotive applications, components are subjected to extreme temperatures and wear. CVD is used to deposit ultra-hard, wear-resistant coatings (like titanium nitride) on cutting tools, drill bits, and engine components, drastically increasing their lifespan and performance. It's also used to create thermal barrier coatings that protect turbine blades from intense heat.

Biomedical Field: Creating Biocompatible Surfaces

Medical implants, such as artificial joints or dental implants, must be accepted by the body without causing a negative reaction. CVD is used to apply inert, biocompatible coatings (like pyrolytic carbon) that improve durability and reduce the risk of rejection or wear inside the body.

Research and Materials Science: Pushing Boundaries

In laboratories, CVD furnaces are workhorses for developing the next generation of materials. Researchers use them to synthesize novel materials like graphene, carbon nanotubes, and other two-dimensional substances, exploring properties that could lead to future technological breakthroughs.

Understanding the Trade-offs

While powerful, CVD is a specialized process chosen for specific reasons. It is not a universal solution for all coating or heating needs.

High Cost and Complexity

CVD systems are expensive to build and operate. They require sophisticated vacuum systems, precise gas flow controllers, and careful management of high temperatures, making them more complex than standard industrial furnaces.

Slow Deposition Rates

Building a film atom by atom is a meticulous and often slow process. For applications requiring thick coatings on large parts, other methods like thermal spraying may be more practical and cost-effective.

Hazardous Precursor Materials

The gases used in CVD can be highly toxic, flammable, or corrosive. This necessitates significant safety infrastructure and specialized handling protocols, adding to the operational overhead.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on the desired outcome for your material.

- If your primary focus is creating active electronic or optical properties: CVD is often the only viable choice due to its precision in controlling film purity and thickness.

- If your primary focus is enhancing the surface hardness of a critical component: CVD is a leading option for creating thin, durable, and high-performance protective layers.

- If your primary focus is simply heat-treating or sintering a bulk material: A more conventional vacuum, retort, or tube furnace without the complex gas delivery systems is a more direct and cost-effective solution.

Ultimately, choosing CVD is a decision to engineer a material's surface for a specific, high-value function.

Summary Table:

| Industry | Primary Purpose of CVD Furnace |

|---|---|

| Semiconductors and Electronics | Deposit thin films for transistors, circuits, solar cells, and LEDs |

| Optics and Photonics | Apply anti-reflective, reflective, and protective coatings on lenses and mirrors |

| Aerospace and Tooling | Create wear-resistant and thermal barrier coatings for tools and engine parts |

| Biomedical Field | Apply biocompatible coatings on implants like joints and dental devices |

| Research and Materials Science | Synthesize novel materials such as graphene and carbon nanotubes |

Leverage KINTEK's exceptional R&D and in-house manufacturing for advanced high-temperature furnace solutions. Our diverse product line, including CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, is backed by strong deep customization to precisely meet your unique experimental needs. Contact us today to enhance your lab's capabilities with tailored solutions! Get in touch now

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films