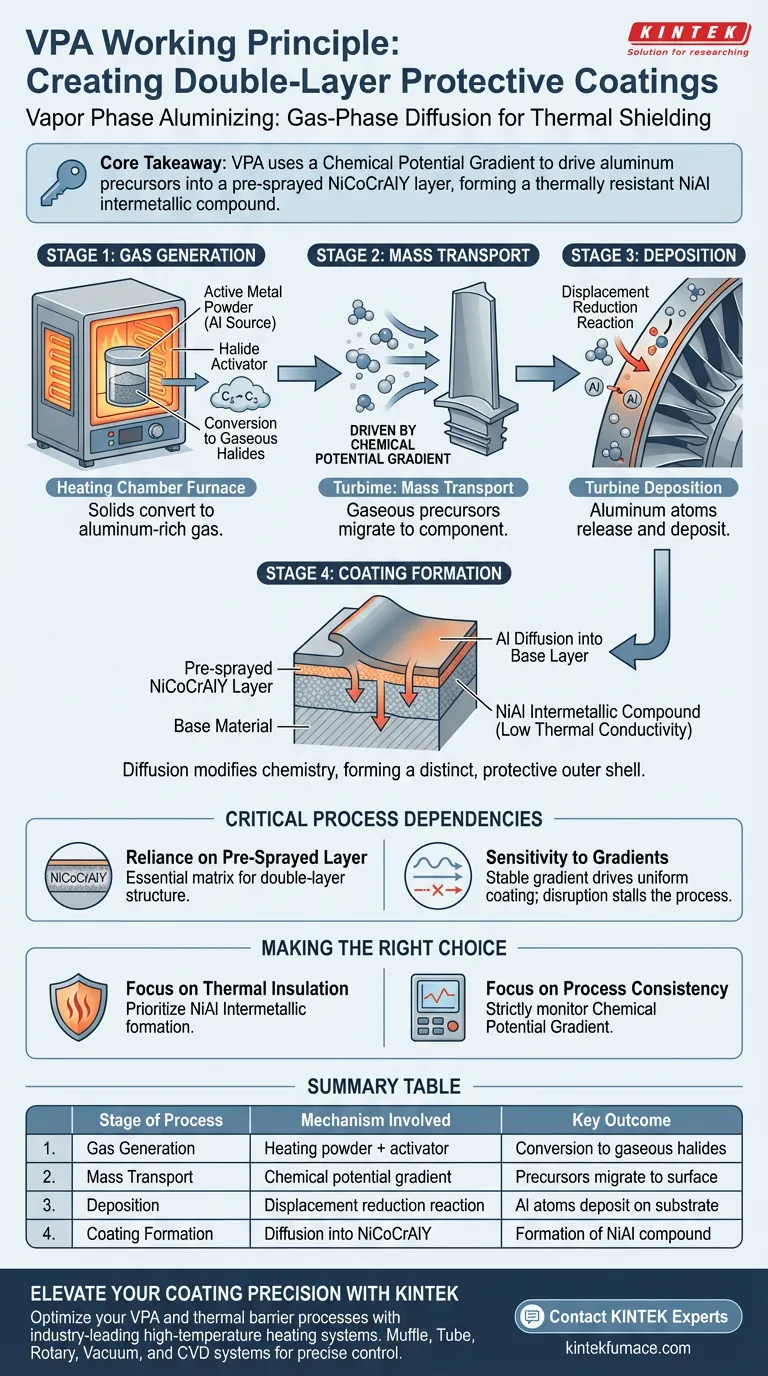

Vapor Phase Aluminizing (VPA) functions as a specialized gas-phase diffusion process conducted within a controlled heating chamber furnace. By heating a mixture of active metal powder and a halide activator, the equipment generates aluminum-rich gases that are driven to the target surface, where they diffuse into a base layer to create a thermally resistant shield.

Core Takeaway: VPA relies on a chemical potential gradient to drive gaseous aluminum precursors into a pre-sprayed NiCoCrAlY layer. This reaction transforms the surface into an NiAl intermetallic compound, providing a double-layer coating known for extremely low thermal conductivity.

The Mechanism of Gas Generation

Inside the Heating Chamber

The process begins inside a heating chamber furnace. The equipment utilizes a container specifically designed to hold active metal powder mixed with a halide activator.

Conversion to Gaseous Halides

As the furnace applies heat, a chemical transformation occurs within the container. The solid aluminum source reacts with the activator, converting the aluminum into gaseous halides.

This phase change from solid to gas is the fundamental first step. It creates the medium necessary to transport aluminum atoms to the component.

Transport and Deposition Principles

Driven by Chemical Potential

The movement of the gas is not random. It is driven by a chemical potential gradient.

This gradient acts as a force, effectively pushing the gaseous precursors from the source container toward the surface of the turbine blade or component.

The Displacement Reduction Reaction

Once the gaseous halides reach the blade surface, they undergo a displacement reduction reaction.

This chemical reaction releases the aluminum from the gas phase, depositing it directly onto the surface of the component.

Forming the Double-Layer Structure

Diffusion into the Base Layer

The VPA process is designed to work in tandem with a pre-existing coating. The deposited aluminum diffuses into a pre-sprayed NiCoCrAlY layer.

This is not merely a surface overlay; it is a modification of the existing layer's chemistry through diffusion.

The Resulting Intermetallic Compound

The diffusion of aluminum into the NiCoCrAlY layer results in the formation of a distinct outer layer.

This new outer shell consists of an NiAl intermetallic compound. The primary technical advantage of this specific compound is its extremely low thermal conductivity, which provides the necessary thermal protection.

Critical Process Dependencies

Reliance on the Pre-Sprayed Layer

The effectiveness of this specific VPA application depends entirely on the presence of the NiCoCrAlY layer.

Without this specific pre-sprayed base, the aluminum would not have the necessary matrix to form the desired double-layer structure.

Sensitivity to Gradients

The process relies heavily on maintaining a stable chemical potential gradient.

If this gradient is disrupted, the transport of gaseous precursors to the blade surface will stall, resulting in incomplete coating or insufficient aluminum diffusion.

Making the Right Choice for Your Goal

To effectively utilize VPA for double-layer protection, you must align your process controls with the desired material properties.

- If your primary focus is thermal insulation: Prioritize the formation of the NiAl intermetallic compound, as this provides the low thermal conductivity required for high-heat environments.

- If your primary focus is process consistency: strictly monitor the chemical potential gradient inside the furnace, as this is the engine that drives the coating thickness and uniformity.

Success in Vapor Phase Aluminizing lies in precisely controlling the conversion of solid powder to gas to chemically transform a standard alloy coating into a high-performance thermal barrier.

Summary Table:

| Stage of Process | Mechanism Involved | Key Outcome |

|---|---|---|

| Gas Generation | Heating active metal powder + halide activator | Conversion of solids into gaseous aluminum halides |

| Mass Transport | Driven by chemical potential gradient | Gaseous precursors migrate toward the component surface |

| Deposition | Displacement reduction reaction | Aluminum atoms release and deposit onto the substrate |

| Coating Formation | Diffusion into NiCoCrAlY base layer | Formation of low-thermal-conductivity NiAl intermetallic compound |

Elevate Your Coating Precision with KINTEK

Ready to optimize your Vapor Phase Aluminizing (VPA) and thermal barrier coating processes? KINTEK provides industry-leading high-temperature heating systems designed for the most demanding gas-phase diffusion applications.

Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or industrial needs. Whether you are developing NiAl intermetallic compounds for turbine blades or researching advanced double-layer protective coatings, our technology ensures the stable chemical potential gradients and uniform temperature control essential for success.

Contact our technical specialists today to discuss your project requirements!

Visual Guide

References

- Leszek Ułanowicz, Andrzej Dudziński. Heat-Resistant Protective Coatings Applied to Aircraft Turbine Blades by Supersonic Thermal Spraying and Diffusion-Aluminizing. DOI: 10.3390/coatings14121554

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What is the overall significance of CVD in industrial applications? Unlock Atomic-Level Surface Engineering

- What types of materials can be produced using CVD? Unlock Versatile Thin Films and Advanced Materials

- What physical conditions affect graphene production? Master CVD Synthesis for High-Quality Results

- What is a Chemical Vapor Deposition (CVD) furnace used for? Precision Thin Films for Electronics & Materials

- What advantages does the DLI-PP-CVD system offer for MoS2 nanosheet growth? Achieve Molecular Precision & Scalability

- What are common precursors used in CVD? Discover Key Types for Superior Thin Films

- What is Laser Chemical Vapor Deposition (LCVD)? Precision Micro-Scale 3D Printing for Thin Films

- How are CVD processes categorized based on operational conditions? Explore Key Types and Applications