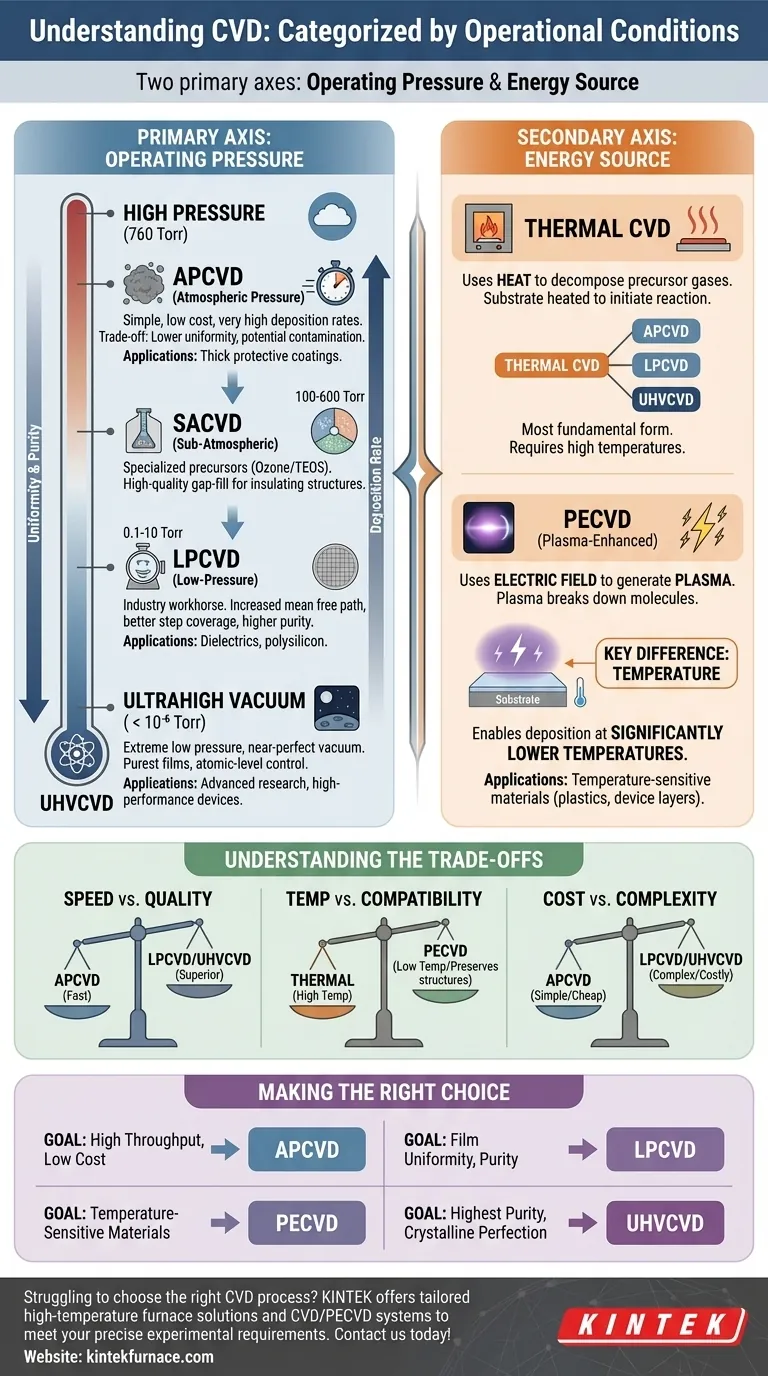

In practice, Chemical Vapor Deposition (CVD) processes are categorized along two primary axes: their operating pressure and the energy source used to drive the reaction. Based on pressure, the main types are Atmospheric Pressure CVD (APCVD), Low-Pressure CVD (LPCVD), and Ultrahigh Vacuum CVD (UHVCVD). Each pressure regime is chosen to solve a specific problem related to film quality, purity, and deposition speed.

The choice of a CVD process is fundamentally a trade-off. Lowering the operating pressure generally improves film uniformity and purity at the cost of deposition rate and equipment complexity, while alternative energy sources like plasma allow for deposition at lower temperatures.

The Primary Axis: Operating Pressure

The pressure inside the CVD reactor directly controls the behavior of gas molecules, which in turn dictates the quality of the resulting thin film. This is the most common way to classify CVD systems.

Atmospheric Pressure CVD (APCVD)

APCVD operates at standard atmospheric pressure (760 Torr). Because it doesn't require expensive vacuum systems, it is relatively simple and inexpensive.

This process enables very high deposition rates. However, the high density of gas molecules leads to gas-phase reactions and a shorter mean free path, which can result in lower film uniformity and potential particle contamination.

Low-Pressure CVD (LPCVD)

LPCVD is the workhorse of the semiconductor industry. It operates at reduced pressures, typically in the range of 0.1 to 10 Torr.

By lowering the pressure, the mean free path—the average distance a molecule travels before colliding with another—is significantly increased. This leads to more uniform deposition across the wafer surface, better step coverage over complex topographies, and higher film purity.

Ultrahigh Vacuum CVD (UHVCVD)

UHVCVD operates at extremely low pressures, typically below 10⁻⁶ Torr. This environment is as close to a perfect vacuum as is practically achievable.

The primary goal of UHVCVD is to create the purest possible films with precise atomic-level control, such as for epitaxial growth. The near-absence of background contaminants makes it ideal for advanced research and fabricating high-performance electronic devices where even trace impurities can degrade performance.

Sub-Atmospheric CVD (SACVD)

SACVD is a more specialized process that operates at pressures between LPCVD and APCVD (roughly 100-600 Torr). It is often used with specific precursors, like ozone and TEOS, to deposit high-quality silicon dioxide films with excellent gap-fill capabilities for insulating structures.

Beyond Pressure: The Role of the Energy Source

While pressure is critical, it doesn't tell the whole story. The method used to supply energy for the chemical reaction is another key differentiator.

Thermal CVD

This is the most fundamental form of CVD, where heat is the sole energy source used to decompose the precursor gases. The processes described above—APCVD, LPCVD, and UHVCVD—are all typically forms of thermal CVD. The substrate is heated to a temperature high enough to initiate the chemical reaction on its surface.

Plasma-Enhanced CVD (PECVD)

PECVD uses an electric field to generate a plasma (an ionized gas) inside the reactor. This plasma provides the energy to break down the precursor molecules, rather than relying solely on high temperatures.

The key advantage of PECVD is its ability to deposit high-quality films at significantly lower temperatures than thermal CVD. This makes it essential for depositing materials onto substrates that cannot withstand high heat, such as completed device layers or plastics.

Understanding the Trade-offs

Selecting a CVD process is an engineering decision based on balancing competing requirements. There is no single "best" method; each has its purpose.

Speed vs. Quality

There is a direct trade-off between deposition speed and film quality. APCVD is fast and cheap but produces lower-quality films. LPCVD and UHVCVD are slower but produce superior uniformity and purity.

Temperature vs. Substrate Compatibility

High-temperature thermal processes can damage or alter underlying layers on a wafer. PECVD solves this problem by allowing deposition at low temperatures, preserving the integrity of temperature-sensitive structures.

Cost vs. Complexity

Simplicity correlates with cost. An APCVD system is the least complex and cheapest. As you move to LPCVD and especially UHVCVD, the need for sophisticated vacuum pumps, seals, and monitoring equipment dramatically increases both the capital and operational cost.

Making the Right Choice for Your Goal

Your application's primary requirement will guide your selection of the appropriate CVD process.

- If your primary focus is high throughput and low cost: APCVD is often the most suitable choice for applications where film perfection is not the top priority, such as thick protective coatings.

- If your primary focus is film uniformity and purity for standard applications: LPCVD provides the best balance of quality and efficiency and is a semiconductor industry standard for dielectrics and polysilicon.

- If your primary focus is depositing on temperature-sensitive materials: PECVD is the necessary choice, as it allows for high-quality film growth without causing thermal damage to underlying structures.

- If your primary focus is achieving the highest possible purity and crystalline perfection: UHVCVD is required for advanced research and cutting-edge devices where atomic-level control is paramount.

Understanding these core trade-offs allows you to select the precise CVD method that aligns with your specific material, performance, and cost requirements.

Summary Table:

| Category | Types | Key Characteristics | Common Applications |

|---|---|---|---|

| By Pressure | APCVD, LPCVD, UHVCVD, SACVD | Varies in pressure (e.g., 760 Torr for APCVD, 0.1-10 Torr for LPCVD) to control film uniformity, purity, and deposition rate | APCVD for cost-effective coatings, LPCVD for semiconductors, UHVCVD for high-purity devices |

| By Energy Source | Thermal CVD, PECVD | Uses heat or plasma for reaction; PECVD enables lower temperature deposition | Thermal CVD for high-temp substrates, PECVD for temperature-sensitive materials like plastics |

Struggling to choose the right CVD process for your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements, whether you're working with semiconductors, research materials, or industrial coatings. Contact us today to discuss how our tailored solutions can enhance your film deposition quality and efficiency!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties