A continuous flow tube reactor, also known as a fixed-bed reactor, serves as the definitive standard for evaluating catalyst performance by rigorously replicating industrial processing conditions. By enabling precise regulation of temperature and pressure while maintaining a steady flow of reactants, this system allows for the accurate measurement of critical metrics such as Space-Time Yield (STY) and product selectivity.

Core Insight: The primary value of this reactor lies in its ability to isolate the catalyst's intrinsic kinetic performance. By operating under high pressure with continuous flow, it effectively filters out the noise of thermodynamic equilibrium and complex side reactions, providing data that is directly scalable to industrial applications.

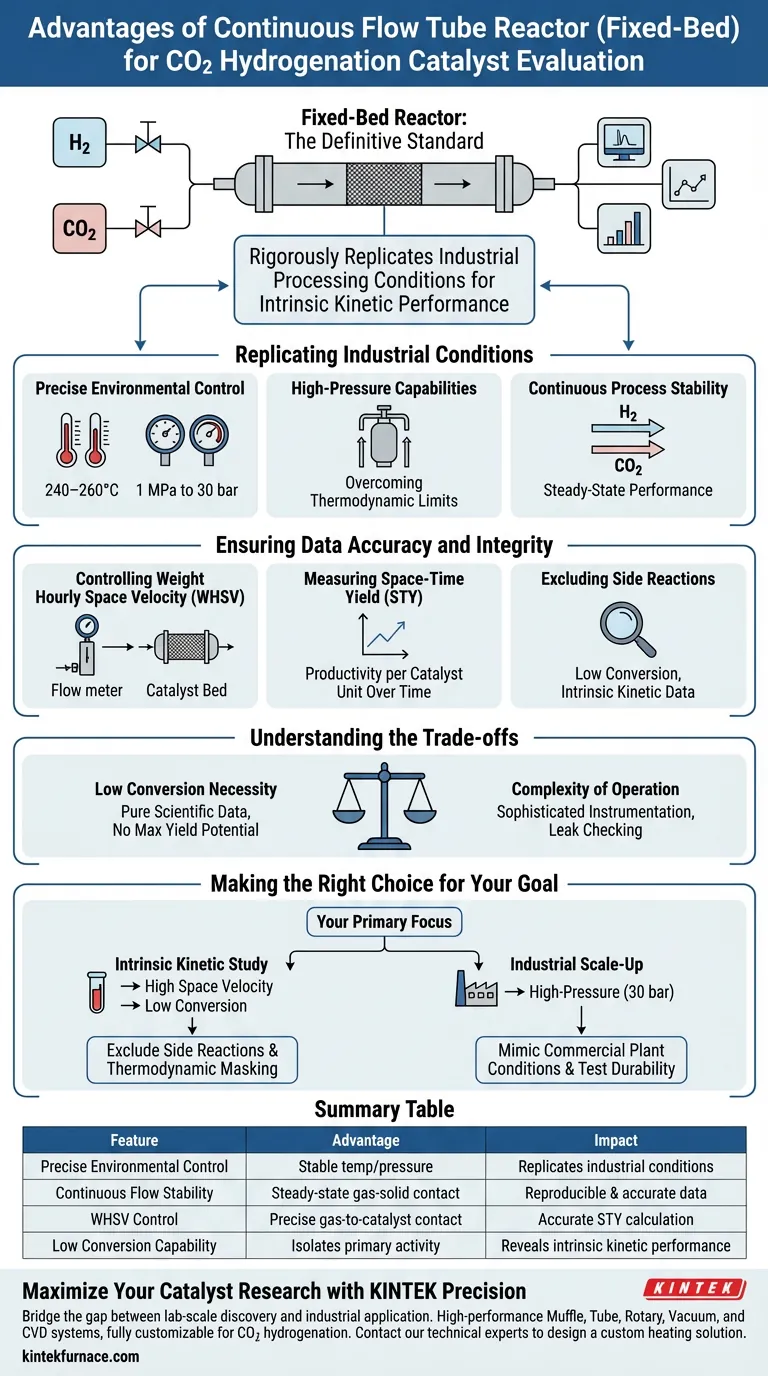

Replicating Industrial Conditions

Precise Environmental Control

To predict how a catalyst will behave in a commercial plant, you must simulate that environment in the lab. Fixed-bed reactors excel at maintaining specific, stable temperatures (e.g., 240–260°C) and pressures.

High-Pressure Capabilities

While basic evaluations might occur at 1 MPa, advanced systems equipped with high-pressure controllers can reach 30 bar. This is critical for processes like methanol synthesis, where overcoming thermodynamic equilibrium limits requires significant pressure.

Continuous Process Stability

Unlike batch reactors, these systems allow reactant gases (H2 and CO2) to flow continuously. This stability ensures that the data collected represents steady-state performance rather than a transient moment in a reaction cycle.

Ensuring Data Accuracy and Integrity

Controlling Weight Hourly Space Velocity (WHSV)

The continuous flow setup allows researchers to dictate the exact Weight Hourly Space Velocity (WHSV). This metric controls how much gas passes over a specific weight of catalyst per hour, ensuring thorough and reproducible gas-solid contact.

Measuring Space-Time Yield (STY)

Because the flow rate and catalyst volume are fixed, you can accurately calculate Space-Time Yield (STY). This is a vital measure of productivity, determining how much product is generated per unit of catalyst over time.

Excluding Side Reactions

By combining high space velocity with precise pressure, researchers can evaluate catalysts at low conversion rates. This technique is essential because it measures the catalyst's primary activity while effectively excluding the influence of complex, secondary side reactions or equilibrium states that distort results.

Understanding the Trade-offs

The "Low Conversion" Necessity

To obtain the most accurate kinetic data (intrinsic selectivity), these reactors often must be operated at low conversion levels. While this yields pure scientific data, it does not immediately demonstrate the maximum yield potential of the catalyst without further modeling.

Complexity of Operation

Achieving stable gas-solid contact and maintaining high pressures (up to 30 bar) requires sophisticated instrumentation. Unlike simpler setups, these reactors demand rigorous leak checking and precise flow calibration to prevent data skewing.

Making the Right Choice for Your Goal

To maximize the value of a continuous flow tube reactor, align your operating parameters with your specific research objectives.

- If your primary focus is Intrinsic Kinetic Study: Operate at high space velocity and low conversion to exclude side reactions and thermodynamic masking.

- If your primary focus is Industrial Scale-Up: Utilize the high-pressure capabilities (up to 30 bar) to mimic commercial plant conditions and test catalyst durability.

Ultimately, the fixed-bed reactor is the bridge between theoretical chemistry and practical application, transforming raw experimental data into scalable industrial process knowledge.

Summary Table:

| Feature | Advantage for Catalyst Evaluation | Impact on Research |

|---|---|---|

| Precise Environmental Control | Stable temperature (240–260°C) and pressure (up to 30 bar) | Replicates industrial-scale conditions |

| Continuous Flow Stability | Maintains steady-state gas-solid contact | Ensures reproducible and accurate data |

| WHSV Control | Dictates precise gas-to-catalyst contact time | Enables accurate Space-Time Yield (STY) calculation |

| Low Conversion Capability | Isolates primary activity from secondary reactions | Reveals intrinsic kinetic performance |

Maximize Your Catalyst Research with KINTEK Precision

Bridge the gap between lab-scale discovery and industrial application. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of CO2 hydrogenation and high-pressure catalyst testing. Whether you need precise flow control or robust high-temperature stability, our lab furnaces provide the accuracy your research deserves.

Ready to scale your results? Contact our technical experts today to design a custom heating solution tailored to your unique research needs.

Visual Guide

References

- Seyed Alireza Vali, Antoni Sánchez. Biochar-supported highly dispersed ultrasmall Cu/ZnO nanoparticles as a highly efficient novel catalyst for CO2 hydrogenation to methanol. DOI: 10.18331/brj2025.12.2.3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the drawbacks of induction heating tube furnaces? High Cost, Metal Tubes, and EMI Issues

- How does sample handling differ between vertical and horizontal tube furnaces? Choose the Right Furnace for Your Lab

- What are the critical functions of a laboratory tube furnace in biomass synthesis? Optimize Your Carbonization Process

- What role does a horizontal tube furnace play in preparing 25%-ASHC porous carbon? Master Precise Thermal Pyrolysis

- What role does a tube resistance furnace play during the oxidative roasting phase of ore pellets? Master Heat Precision

- What role does a tube furnace play in the high-temperature heat treatment stage of catalyst fabrication?

- What physical conditions does a high-temperature tube furnace provide? Optimize Lignin Carbonization Success

- What is the technical significance of a horizontal tube furnace with a sliding rail for NiOx annealing? Enhance Control