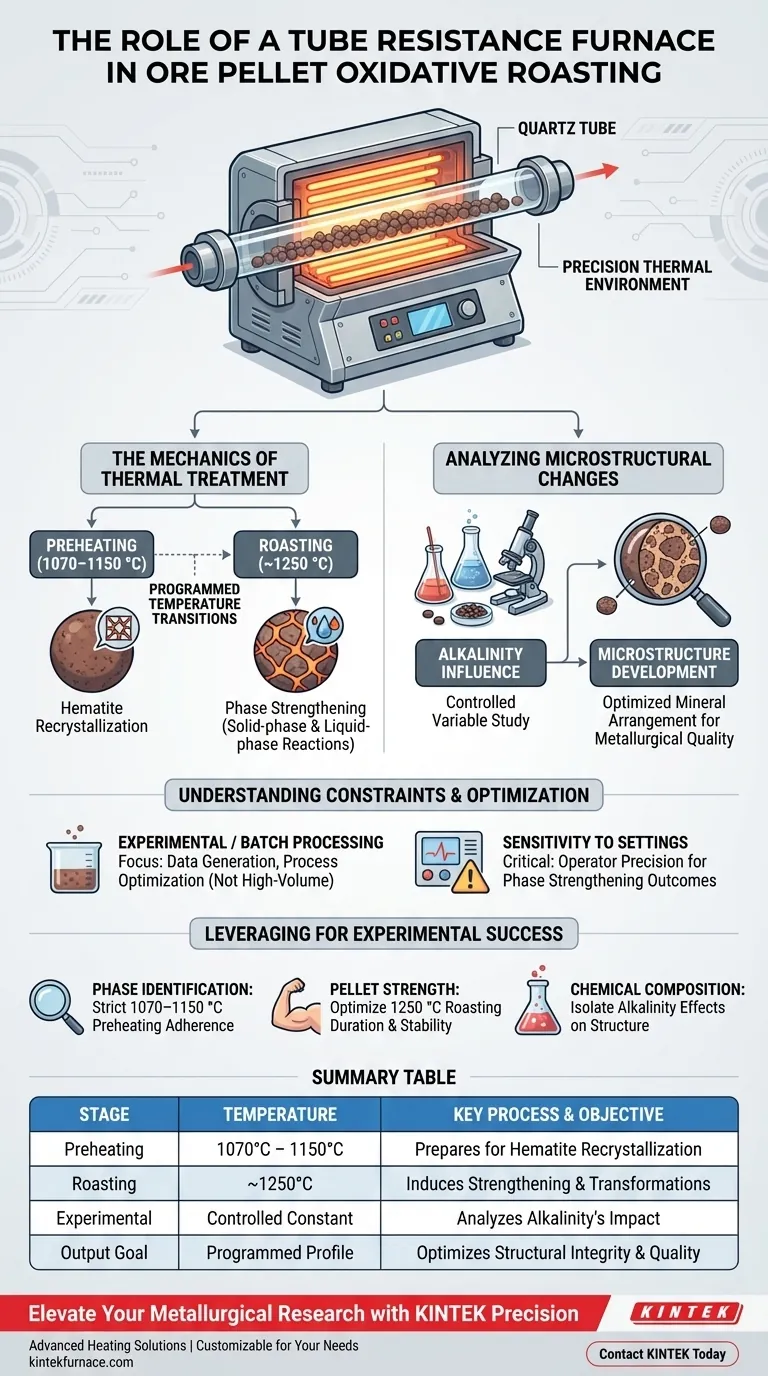

A tube resistance furnace acts as a precision thermal environment specifically designed to manage the critical phases of oxidative roasting for ore pellets. It functions by executing programmed temperature transitions—switching between preheating (1070–1150 °C) and roasting (1250 °C)—to drive essential chemical and physical transformations like hematite recrystallization and phase strengthening.

The primary value of a tube resistance furnace lies in its ability to isolate and control thermal variables. It serves as an experimental platform that allows researchers to determine exactly how factors like alkalinity influence the microstructure and strength of the final pellet.

The Mechanics of Thermal Treatment

Precision Temperature Control

The fundamental role of the furnace is to provide a strictly controlled high-temperature environment. Unlike general heating units, it is designed to execute specific thermal profiles required for metallurgical changes.

It manages the transition between two distinct thermal stages. First, it maintains preheating temperatures typically ranging from 1070 °C to 1150 °C.

Subsequently, it ramps up to roasting temperatures around 1250 °C. This programmable switching capability ensures the pellets are subjected to the exact conditions needed for specific reactions to occur.

Inducing Phase Transformations

The heat applied by the furnace is not merely for drying; it is the catalyst for hematite recrystallization.

At these elevated temperatures, the internal structure of the ore pellet begins to reorganize. The furnace environment promotes this crystallization, which is vital for the pellet's structural integrity.

Strengthening Reactions

Beyond recrystallization, the furnace facilitates solid-phase and liquid-phase strengthening reactions.

These reactions create the internal bonds that give the pellet its physical strength. The controlled heat ensures these reactions occur uniformly throughout the pellet.

Analyzing Microstructural Changes

The Impact of Alkalinity

The furnace serves as a core experimental platform for studying chemical variables.

It is specifically used to observe how alkalinity affects the mineral phase composition of the pellets. By keeping thermal conditions constant, researchers can attribute microstructural changes directly to the alkalinity levels.

Microstructure Development

The ultimate goal of using this furnace is to understand and optimize the pellet's microstructure.

The interplay between the preheating and roasting phases largely determines the final arrangement of mineral phases. This microstructural evolution is what dictates the metallurgical quality of the processed ore.

Understanding the Operational Constraints

Scale and Throughput

It is important to recognize that a tube resistance furnace is primarily an experimental or batch-processing tool.

It is designed for precise analysis and parameter definition rather than high-volume mass production. Its strength lies in data generation and process optimization, not in bulk material throughput.

Sensitivity to Programmed Settings

The quality of the output is entirely dependent on the accuracy of the programmed settings.

Because the furnace is a "strictly controlled" environment, slight deviations in the preheating or roasting temperature inputs can significantly alter the phase strengthening outcomes. Operator precision in setting the thermal profile is critical.

Leveraging the Furnace for Experimental Success

To maximize the utility of a tube resistance furnace in your metallurgical studies, consider the following approach based on your specific objectives:

- If your primary focus is Phase Identification: strict adherence to the 1070–1150 °C preheating window is essential to prepare the material for proper hematite recrystallization.

- If your primary focus is Pellet Strength: concentrate on optimizing the duration and stability of the 1250 °C roasting phase to maximize liquid-phase strengthening reactions.

- If your primary focus is Chemical Composition: utilize the furnace as a constant variable to isolate how changing alkalinity levels alter the internal mineral structure.

Precision control over the thermal profile is the defining factor in optimizing pellet quality using this technology.

Summary Table:

| Stage | Temperature Range | Key Process & Objective |

|---|---|---|

| Preheating | 1070°C – 1150°C | Prepares material for hematite recrystallization |

| Roasting | ~1250°C | Induces liquid-phase strengthening & phase transformations |

| Experimental | Controlled Constant | Analyzes impact of alkalinity on mineral microstructure |

| Output Goal | Programmed Profile | Optimizes pellet structural integrity and metallurgical quality |

Elevate Your Metallurgical Research with KINTEK Precision

Unlock the full potential of your ore pellet analysis with KINTEK’s advanced heating solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to provide the strict thermal profiles required for complex oxidative roasting and phase strengthening.

Whether you are optimizing alkalinity levels or perfecting hematite recrystallization, our lab high-temp furnaces are fully customizable to meet your unique research needs.

Ready to achieve superior pellet quality and data precision?

Contact KINTEK Today to Consult with Our Experts

Visual Guide

References

- Yufeng Guo, Xinyao Xia. Optimizing High-Al2O3 Limonite Pellet Performance: The Critical Role of Basicity in Consolidation and Reduction. DOI: 10.3390/met15070801

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is a 70mm tube furnace and what is its primary use? Unlock Precision in Material Processing

- What critical conditions does a High-Temperature Tube Furnace provide for NiO-CNF? Master Hybrid Material Synthesis

- What is the purpose of pre-treating quartz tube reactors? Achieve High-Purity CVT Crystal Growth with Precision

- What are the primary applications of lab tubular furnaces in material science and engineering? Precision Heat for Advanced Materials

- What makes a lab tube furnace a versatile tool in material science and engineering? Unlock Precise Material Control

- What is a tubular furnace used for? A Guide to Precise High-Temperature Processing

- How is a high-temperature tube furnace utilized for biochar activation? Enhance Porosity with CO2 Etching

- What is the function of a tube furnace for bond-coated substrates? Ensure TBC Durability with Controlled Pre-Oxidation