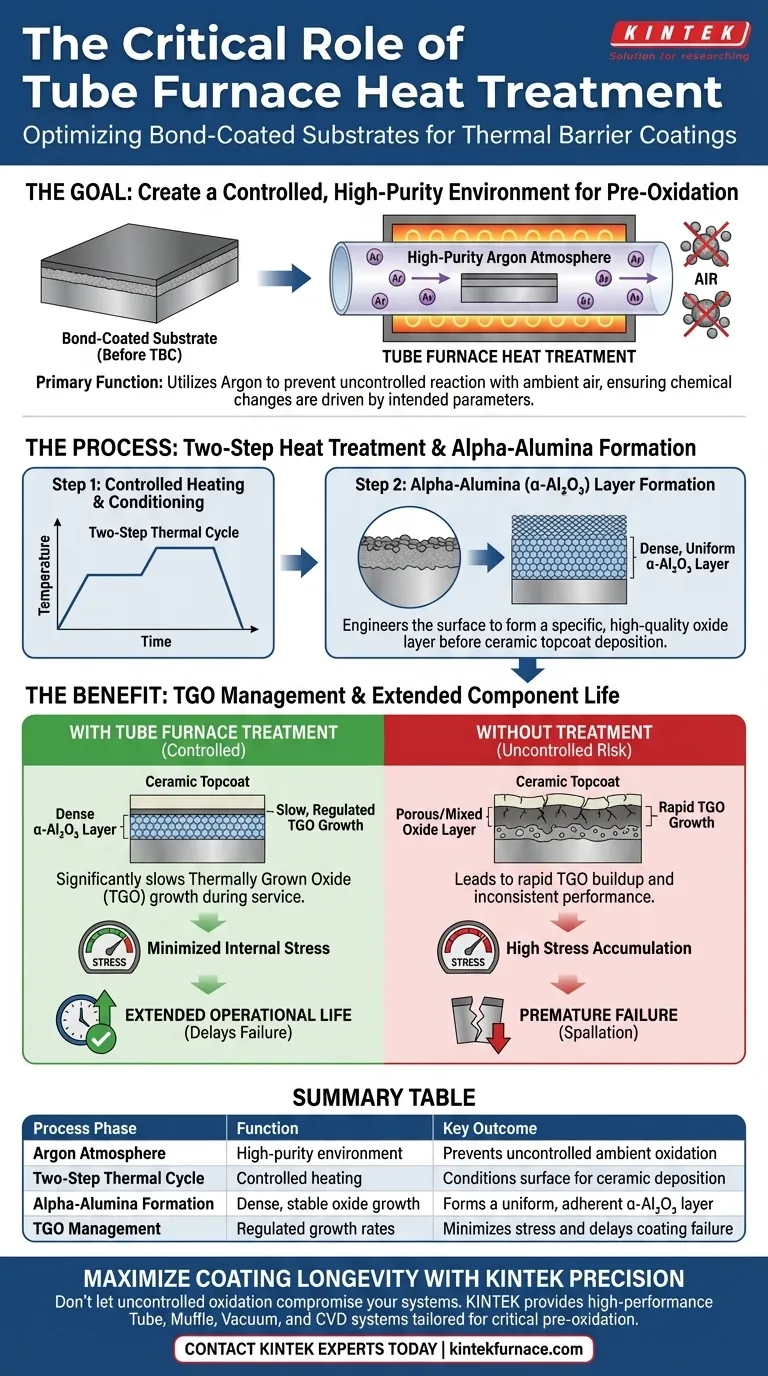

The primary function of using a tube furnace in this context is to create a controlled, high-purity environment for pre-oxidation. Specifically, it utilizes an argon atmosphere to facilitate a two-step heat treatment of the bond-coated substrate. This process engineers the surface of the bond coat to form a specific, high-quality oxide layer before the final ceramic topcoat is applied.

By pre-forming a dense, uniform alpha-alumina layer in a controlled environment, the tube furnace treatment significantly slows future oxide growth during service. This delays failure-inducing stresses and effectively extends the operational life of the thermal barrier coating.

The Mechanics of Controlled Pre-Oxidation

Establishing a High-Purity Environment

The tube furnace is essential because it allows for the introduction of high-purity argon gas.

This prevents uncontrolled reaction with ambient air. It ensures that the chemical changes occurring on the substrate are driven strictly by the intended heat treatment parameters.

The Two-Step Heat Treatment

Inside this controlled atmosphere, the substrate undergoes a specific two-step thermal cycle.

This thermal profile is designed not just to heat the part, but to condition the bond coat chemically and physically. It prepares the surface for the subsequent deposition of the ceramic topcoat.

Optimizing the Interface Layer

Formation of Alpha-Alumina

The critical output of this process is the pre-formation of an alpha-alumina ($\alpha-Al_2O_3$) layer.

Unlike mixed oxides that might form in open air, the tube furnace ensures this layer is dense and uniform. This specific crystalline structure provides superior adherence and stability.

Controlling Thermally Grown Oxides (TGO)

The pre-formed alpha-alumina layer acts as a protective barrier or template.

During actual service, this layer significantly slows the growth of Thermally Grown Oxides (TGO). By regulating how fast the oxide thickens under operational heat, the treatment prevents the rapid buildup of internal pressure.

Extending Component Life

Rapid TGO growth is a primary cause of coating failure due to stress accumulation.

By delaying the onset of these critical stresses, the tube furnace treatment directly contributes to a longer thermal cycle life for the coated component.

Understanding the Necessity of Control

The Risk of Improper Oxidation

Without the precise environment of a tube furnace, the bond coat may oxidize unevenly or form less stable oxide phases.

If the initial oxide layer is porous or chemically mixed, it cannot effectively retard TGO growth during service. This leads to premature spallation (flaking) of the topcoat.

Process Stability vs. Speed

While adding a heat treatment step increases process time, it is a trade-off for predictability.

Skipping this controlled pre-oxidation relies on the uncertain formation of oxides during the initial service cycles, which often leads to inconsistent performance and reduced durability.

Making the Right Choice for Your Goal

To maximize the performance of your thermal barrier coatings, consider how this heat treatment aligns with your objectives:

- If your primary focus is maximizing service life: Implement the tube furnace treatment to ensure a dense alpha-alumina layer forms, which delays stress-induced failure.

- If your primary focus is process reliability: Use the high-purity argon environment to eliminate variables and ensure a uniform starting condition for every substrate.

Controlled pre-oxidation is not just a heating step; it is a foundational process that defines the longevity of the entire coating system.

Summary Table:

| Process Phase | Function | Key Outcome |

|---|---|---|

| Argon Atmosphere | High-purity environment | Prevents uncontrolled ambient oxidation |

| Two-Step Thermal Cycle | Controlled heating | Conditions surface for ceramic deposition |

| Alpha-Alumina Formation | Dense, stable oxide growth | Forms a uniform, adherent $\alpha-Al_2O_3$ layer |

| TGO Management | Regulated growth rates | Minimizes stress and delays coating failure |

Maximize Your Coating Longevity with KINTEK Precision

Don't let uncontrolled oxidation compromise your thermal barrier systems. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Tube, Muffle, Vacuum, and CVD systems tailored for critical pre-oxidation and heat treatment protocols. Whether you require standard lab high-temp furnaces or a fully customizable solution to meet unique research needs, our technology ensures the thermal stability and process reliability your substrates demand.

Ready to extend the operational life of your components? Contact our technical experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- Robert Vaßen. Insight into the Process-Microstructure-Property Relationship: Single Splat Analysis, Adhesion Testing, and Thermal Cycling of Inner Diameter (ID) Thermal Barrier Coatings. DOI: 10.21203/rs.3.rs-8250483/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is a high-precision laboratory balance installed in a tube furnace? Master Thermal Isolation for Precise Data

- How does an alumina tube furnace work? Achieve Precise, Contamination-Free Heating

- What are the key heat treatment processes performed in horizontal furnaces? Master Annealing, Hardening, and More

- Why is a tube furnace with an argon atmosphere required for zeolite stabilization? Protect Your Material Structure

- Why is a silicate glass fixed-bed reactor used instead of stainless steel? Ensure Pure Methanol Decomposition Data

- Why are high-temperature tube furnaces essential for perovskite catalysts? Precision Shaping & Crystallization

- How does a high-temperature tube furnace facilitate Fe-Nx-C electrocatalyst formation? Expert Synthesis Insights

- How does a tube furnace generate high temperatures? Efficient, Precise Heating for Your Lab