A tube furnace generates high temperatures by converting electrical energy into heat through a process known as electrical resistance heating. Specialized heating elements, strategically placed around a central ceramic tube, resist the flow of an electrical current. This resistance causes the elements to heat up intensely, radiating thermal energy into the furnace's core and onto the sample inside. The entire assembly is encased in high-grade thermal insulation to trap this heat, allowing the furnace to reach very high temperatures efficiently.

The effectiveness of a tube furnace stems from a simple but powerful combination: high-resistance heating elements generate the heat, dense insulation contains it, and a sophisticated control system regulates it with high precision.

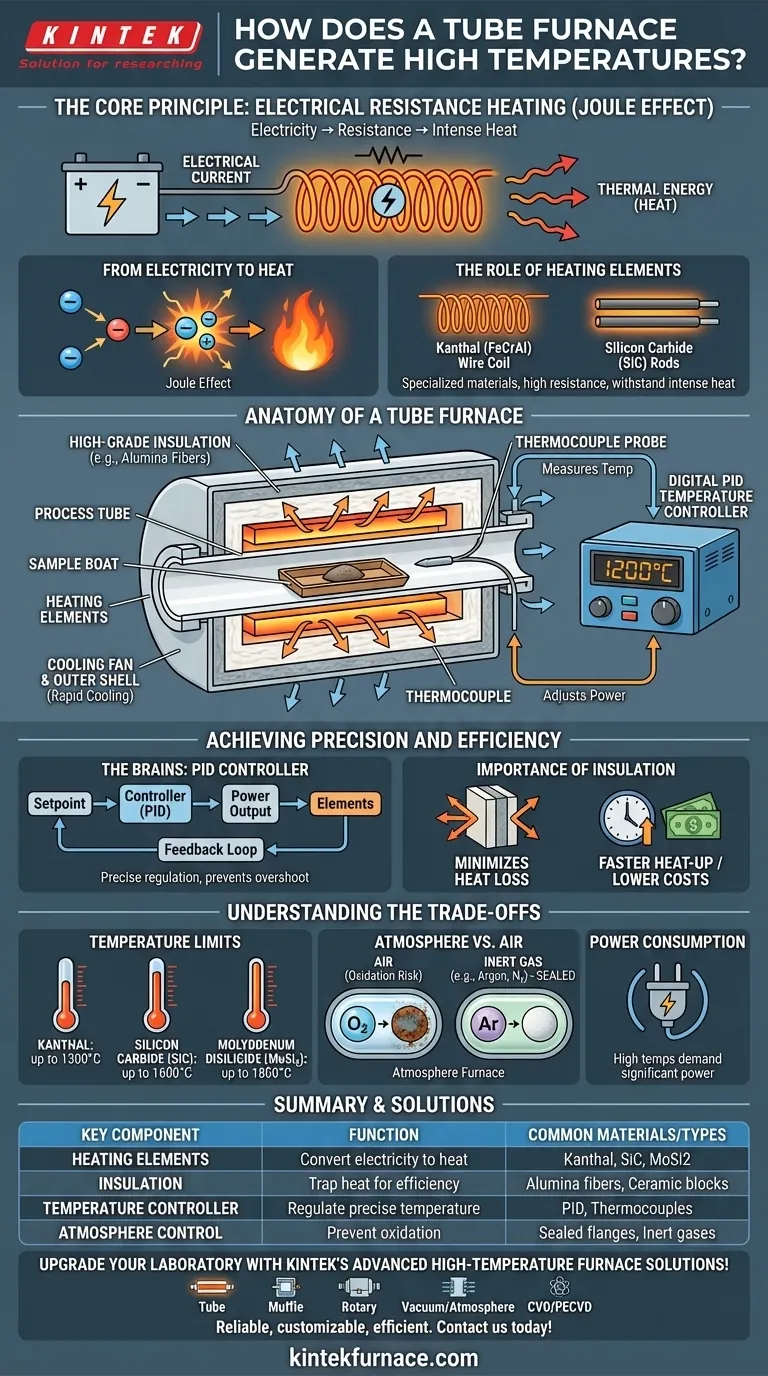

The Core Principle: Electrical Resistance Heating

The fundamental mechanism behind a tube furnace is the Joule effect, a basic principle of physics. This process is engineered into a highly controlled and efficient system.

From Electricity to Heat

At its heart, the furnace operates like a simple resistor. When an electric current is passed through a material with high electrical resistance, the electrical energy cannot pass through easily. This energy is converted directly into thermal energy, or heat.

The Role of Heating Elements

To generate extreme temperatures, the furnace uses heating elements made from specialized materials chosen for two key properties: high electrical resistance and the ability to withstand intense heat without melting or degrading.

Common materials include Kanthal (an iron-chromium-aluminum alloy), which is often wound into a wire coil, and Silicon Carbide (SiC) rods. These elements are arranged around the exterior of the central process tube.

The Insulating Matrix

The heating elements are embedded within a thermally insulating matrix. This insulation, often made of high-purity alumina or other ceramic fibers, is critical. It prevents heat from escaping into the surrounding environment, focusing all the thermal energy inward toward the central tube. This is the key to both reaching high temperatures and maintaining energy efficiency.

Achieving Precision and Efficiency

Generating heat is only half the battle. A tube furnace's real value lies in its ability to achieve and hold a precise temperature setpoint reliably and efficiently.

The Brains of the Operation: The Temperature Controller

A modern tube furnace uses an advanced digital temperature controller, typically a PID (Proportional-Integral-Derivative) controller. A thermocouple probe placed near the heating elements constantly measures the temperature and sends this reading back to the controller.

The controller compares the actual temperature to your desired setpoint and precisely adjusts the amount of power sent to the heating elements, preventing overshoot and maintaining a highly stable thermal environment.

The Importance of High-Grade Insulation

Efficiency is a direct result of minimizing heat loss. Tube furnaces use multi-layered insulation, such as double-layer air-cooled shells and lightweight alumina fiber blocks. This design ensures that the energy consumed is used for heating the sample, not the lab, leading to faster heat-up times and lower operational costs.

Rapid Heating and Cooling Cycles

The combination of powerful heating elements and effective insulation allows for a rapid temperature rise. Furthermore, some models incorporate cooling fans between the insulation layers. These fans can be activated to quickly cool the furnace's exterior and, by extension, the interior chamber, reducing the cycle time between experiments.

Understanding the Trade-offs

While highly effective, the design of a tube furnace involves specific engineering choices and limitations that you must understand.

Temperature Limits of Heating Elements

The maximum achievable temperature of a furnace is determined entirely by its heating element material.

- Kanthal (FeCrAl) elements are common and cost-effective for temperatures up to approximately 1300°C.

- Silicon Carbide (SiC) and Molybdenum Disilicide (MoSi2) elements are required for higher-temperature applications, reaching up to 1600°C and 1800°C, respectively.

Atmosphere vs. Air

Heating a sample in the presence of air will cause oxidation at high temperatures. If your process is sensitive to oxygen, you need an "atmosphere tube furnace." These models have sealed flanges and gas ports that allow you to purge the air and fill the tube with an inert gas like argon or nitrogen.

Power Consumption

While tube furnaces are designed for efficiency, reaching and maintaining very high temperatures still demands significant electrical power. The term "low energy consumption" is relative to older, less insulated furnace designs. The power requirements for a high-temperature furnace should not be underestimated.

Making the Right Choice for Your Application

Your specific goal will determine the type of furnace you need.

- If your primary focus is general heating up to 1200°C: A furnace with Kanthal (FeCrAl) heating elements is the most cost-effective and reliable choice.

- If your primary focus is high-temperature processing above 1400°C: You must specify a furnace with Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2) elements.

- If your primary focus is preventing oxidation of your sample: Ensure you select a sealed "atmosphere" tube furnace capable of being purged with an inert gas.

Understanding these core principles empowers you to select and operate a tube furnace with maximum efficiency and precision.

Summary Table:

| Key Component | Function | Common Materials/Types |

|---|---|---|

| Heating Elements | Convert electrical energy to heat via resistance | Kanthal (up to 1300°C), Silicon Carbide (up to 1600°C), Molybdenum Disilicide (up to 1800°C) |

| Insulation | Trap heat for efficiency and high temperatures | Alumina fibers, ceramic blocks |

| Temperature Controller | Regulate and maintain precise temperatures | PID controllers with thermocouples |

| Atmosphere Control | Prevent oxidation in sensitive processes | Sealed flanges for inert gases (e.g., argon, nitrogen) |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable tube furnaces, muffle furnaces, rotary furnaces, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs—whether for general heating, high-temperature processing, or oxidation-sensitive applications. Contact us today to discuss how our furnaces can enhance your efficiency and precision!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide