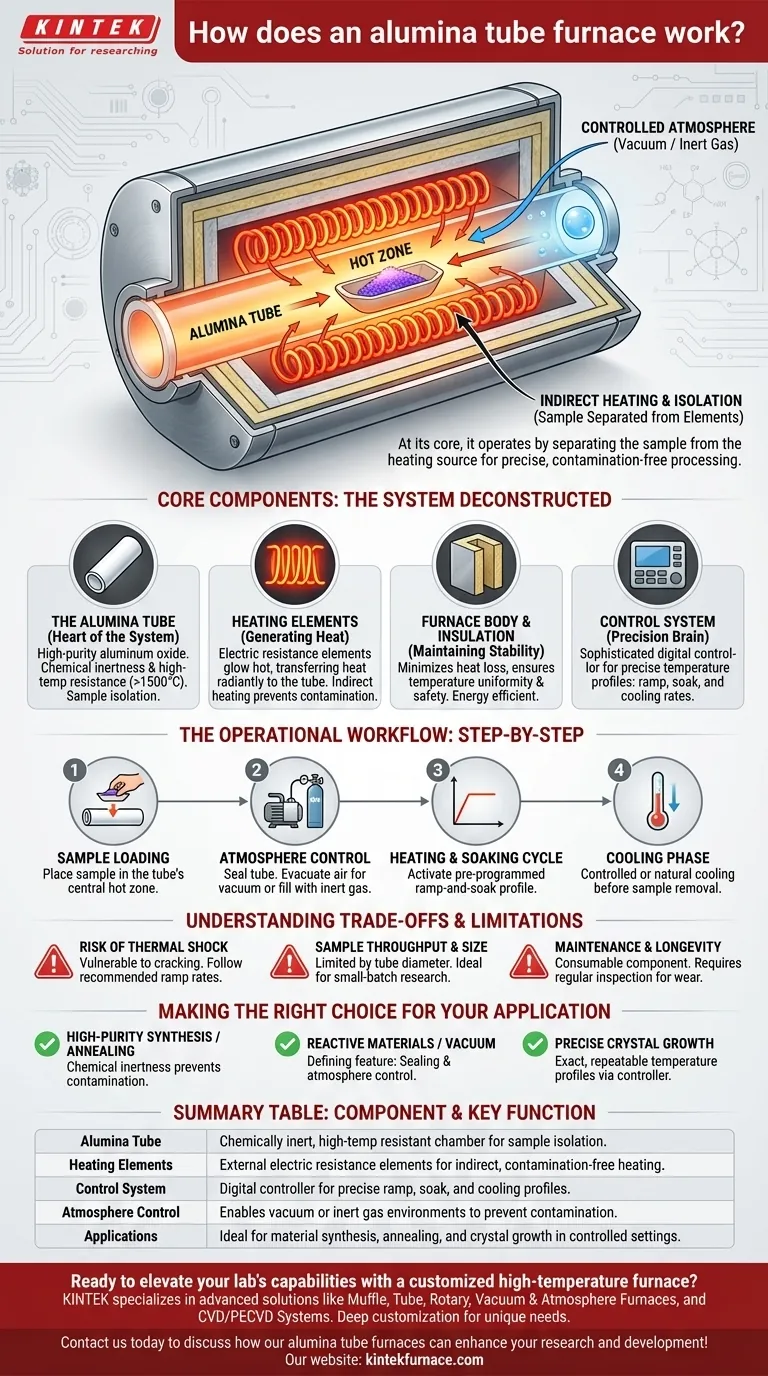

At its core, an alumina tube furnace operates by separating the sample from the heating source. Samples are placed inside a chemically inert, high-purity alumina tube, which is then heated externally by electric resistance elements. This indirect heating method allows for extremely precise temperature control and the ability to maintain a controlled atmosphere (like a vacuum or inert gas) around the sample, free from contamination by the heating elements.

The fundamental design principle of an alumina tube furnace is isolation. By using a thermally stable and chemically non-reactive alumina tube, it creates a pristine micro-environment for material processing that is completely separate from the furnace's heating mechanism.

Deconstructing the Core Components

To truly understand its function, we must first look at the key parts that make up the system. Each component serves a specific purpose that contributes to the furnace's precision and reliability.

The Alumina Tube: The Heart of the System

The central component is the tube itself, typically made of high-purity aluminum oxide (alumina). This material is chosen for its exceptional properties: high-temperature resistance (often exceeding 1500°C) and chemical inertness.

This means the tube will not react with or contaminate the sample being heated, which is critical for high-purity research and materials science.

The Heating Elements: Generating Controlled Heat

The heat is generated by electric resistance heating elements that surround the outside of the alumina tube. These elements are housed within the main furnace body.

When electricity passes through them, they glow hot, transferring heat radiantly to the alumina tube, which in turn heats the sample inside. This separation prevents any potential contamination of the sample from the elements themselves.

The Furnace Body and Insulation: Maintaining Stability

The furnace's outer casing and internal insulation are designed to contain the immense heat generated. High-quality refractory materials minimize heat loss, ensuring temperature stability inside the furnace and keeping the exterior safe to touch.

This insulation is crucial for both energy efficiency and the uniform distribution of heat along the length of the tube.

The Control System: Precision at Your Fingertips

A sophisticated digital controller is the brain of the operation. It allows the user to program precise temperature profiles, including the rate of temperature increase (ramp), the duration at a target temperature (soak), and the cooling rate.

The Operational Workflow Step-by-Step

The daily use of an alumina tube furnace follows a clear, methodical process designed to ensure repeatable and accurate results.

Step 1: Sample Loading

The process begins by placing the material or sample, often in a ceramic boat, inside the alumina tube. The tube is then carefully positioned so the sample sits in the furnace's central "hot zone" for the most uniform heating.

Step 2: Atmosphere Control

For many applications, controlling the atmosphere is essential. The ends of the tube can be sealed with flanges, allowing the air to be pumped out to create a vacuum or replaced with a specific gas (like argon or nitrogen) to create an inert environment.

Step 3: The Heating and Soaking Cycle

Once the furnace is sealed, the user activates the pre-programmed heating cycle. The furnace controller executes the ramp-and-soak profile, gradually bringing the sample to the desired processing temperature and holding it there with high precision.

Step 4: The Cooling Phase

After the heating process is complete, the furnace begins to cool down. This can be a natural, slow cooling process or a controlled ramp-down programmed by the user. The samples can only be safely removed after the furnace has cooled significantly.

Understanding the Trade-offs and Limitations

While powerful, an alumina tube furnace is a specialized tool with inherent trade-offs that every user must understand to operate it safely and effectively.

Risk of Thermal Shock

Alumina is a ceramic, and like most ceramics, it is vulnerable to thermal shock. Heating or cooling the tube too quickly can cause it to crack or shatter. Following the manufacturer's recommended ramp rates is not just a suggestion—it is critical for the longevity of the tube.

Sample Throughput and Size

Tube furnaces are ideal for laboratory-scale research and small-batch production. The diameter of the tube inherently limits the size and volume of the samples that can be processed at one time. They are not designed for high-throughput, industrial-scale manufacturing.

Maintenance and Tube Longevity

The alumina tube is a consumable component. Over time and with repeated thermal cycles, it will degrade and eventually require replacement. Regular inspection for cracks or signs of wear is a necessary part of routine maintenance.

Making the Right Choice for Your Application

An alumina tube furnace is an indispensable tool when used for the right task. Your specific goal determines whether its unique advantages are a perfect match for your needs.

- If your primary focus is high-purity material synthesis or annealing: The chemical inertness of the alumina tube and its separation from the heating elements is its greatest strength, preventing sample contamination.

- If your primary focus is working with reactive materials or in a vacuum: The ability to seal the tube and control the internal atmosphere is the defining feature you should leverage.

- If your primary focus is precise crystal growth or phase transitions: The furnace's sophisticated controller allows you to execute the exact, repeatable temperature profiles required for these sensitive processes.

Ultimately, the alumina tube furnace empowers you to achieve precise thermal processing in a perfectly controlled environment.

Summary Table:

| Component/Feature | Key Function |

|---|---|

| Alumina Tube | Chemically inert, high-temperature resistant chamber for sample isolation |

| Heating Elements | External electric resistance elements for indirect, contamination-free heating |

| Control System | Digital controller for precise ramp, soak, and cooling profiles |

| Atmosphere Control | Enables vacuum or inert gas environments to prevent sample contamination |

| Applications | Ideal for material synthesis, annealing, and crystal growth in controlled settings |

Ready to elevate your lab's capabilities with a customized high-temperature furnace? KINTEK specializes in advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring precise temperature control, contamination-free processing, and reliable performance. Contact us today to discuss how our alumina tube furnaces can enhance your research and development!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety