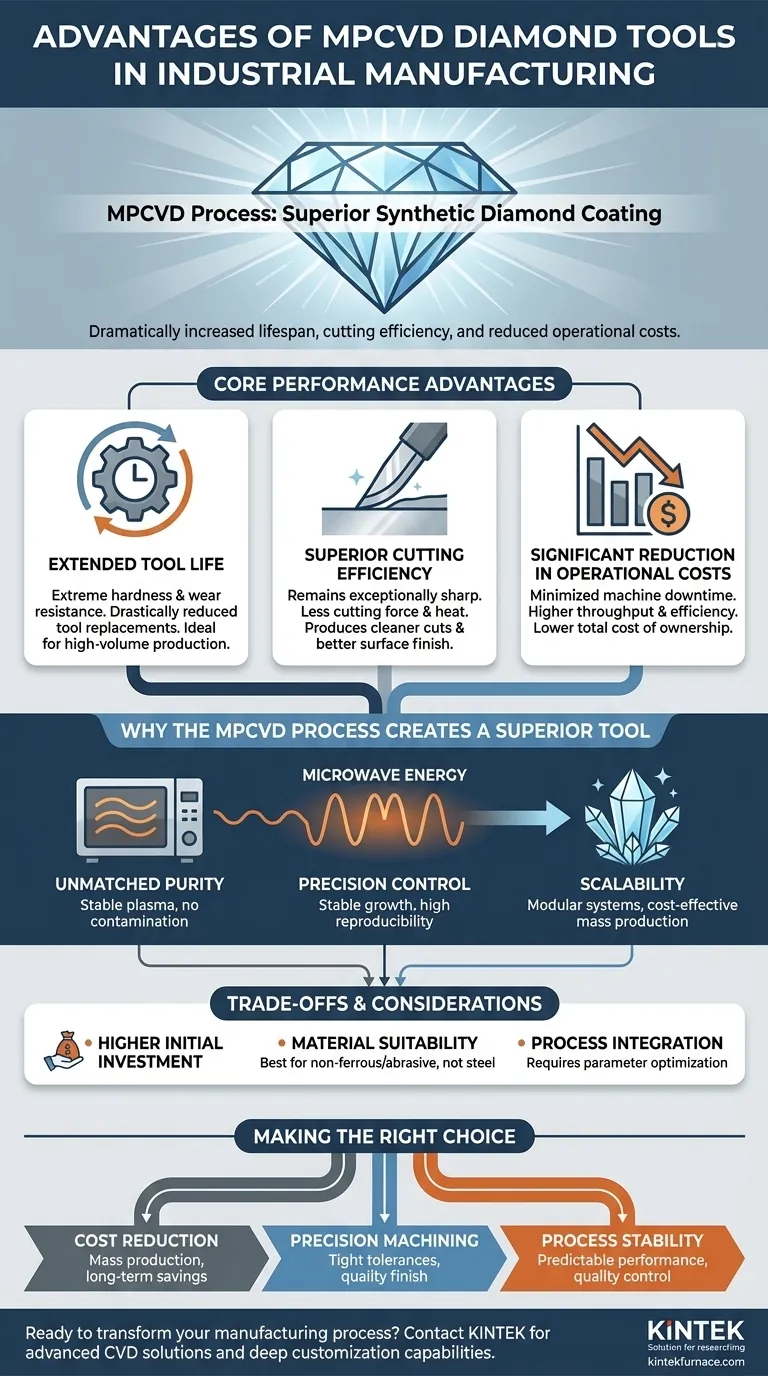

In industrial manufacturing, the primary advantages of MPCVD diamond tools are a dramatic increase in tool lifespan, superior cutting efficiency, and a significant reduction in long-term operational costs. These benefits stem from applying a layer of extremely hard, pure, and uniform synthetic diamond using the Microwave Plasma Chemical Vapor Deposition (MPCVD) process, which minimizes tool replacements and machine downtime.

The central challenge in high-volume and precision manufacturing is not just cutting material, but doing so with predictable consistency and minimal interruption. MPCVD diamond tools solve this by delivering a cutting edge whose performance is defined by the near-perfect structure of its diamond coating, transforming tool wear from a variable into a controlled, manageable factor.

The Core Performance Advantages

The impact of MPCVD diamond coatings is felt directly on the factory floor through tangible improvements in tool performance and a reduction in associated costs.

Extreme Hardness and Extended Tool Life

MPCVD applies a coating with the inherent extreme hardness of diamond. This exceptional wear resistance means the tool maintains its critical cutting geometry for a much longer period than conventional tools.

This directly translates to a massively prolonged tool life, a primary driver for its adoption in demanding industries like automotive and aerospace.

Superior Cutting Efficiency and Surface Finish

Because the diamond edge degrades so slowly, it remains exceptionally sharp throughout its operational use.

A sharper edge requires less cutting force, reduces heat generation, and produces a cleaner cut. This often results in a superior surface finish on the workpiece, potentially eliminating the need for secondary finishing operations.

Significant Reduction in Operational Costs

While the initial investment in an MPCVD tool may be higher, the total cost of ownership is often lower. The primary savings come from a drastic reduction in tool replacements and the associated machine downtime.

In mass production environments, minimizing stoppages for tool changes leads to a direct and substantial increase in overall throughput and efficiency.

Why the MPCVD Process Creates a Superior Tool

The advantages of the final tool are a direct result of the unique capabilities of the MPCVD manufacturing process itself. It is not just about applying diamond; it is about how that diamond is grown.

Unmatched Purity and Crystal Quality

The MPCVD process uses microwave energy to create a stable plasma, which avoids contamination common in other methods (like from hot filaments). This results in a diamond coating with exceptional purity and excellent crystal quality.

A purer, more perfect crystalline structure is inherently stronger and less prone to microscopic fractures, ensuring the cutting edge is robust and consistent.

Precision Control and High Reproducibility

Modern MPCVD systems offer excellent process control over temperature, gas composition, and pressure. This precision allows for a highly stable and uniform diamond growth across the tool surface.

This stability ensures high reproducibility, meaning every tool coated under the same parameters will have virtually identical performance. This predictability is critical for quality control in large-scale industrial applications.

Scalability for Industrial Production

The MPCVD process is inherently stable and scalable. Systems are often modular, allowing for continuous operation over long periods and adaptation to coat larger substrates or batches of tools.

This scalability, combined with high growth rates of up to 150 μm/h, makes MPCVD a cost-effective and viable technology for mass-producing high-performance tools.

Understanding the Trade-offs and Considerations

While MPCVD technology offers clear advantages, it requires a strategic assessment to ensure it aligns with your specific operational needs.

Higher Initial Investment

MPCVD-coated tools typically have a higher upfront cost compared to traditional carbide or simpler coated tools. The economic benefit is realized over time through reduced long-term operating expenses.

Application and Material Suitability

The extreme hardness of diamond makes these tools ideal for machining non-ferrous and abrasive materials like aluminum alloys, composites, and ceramics. However, they are generally not suitable for machining ferrous materials (like steel) due to a chemical reaction at high temperatures that degrades the diamond.

Process Integration

Adopting MPCVD tools is not just a direct swap. Optimizing cutting speeds, feed rates, and cooling strategies is necessary to leverage the full potential of the tool and maximize the return on investment.

Making the Right Choice for Your Application

To determine if MPCVD diamond tools are the right fit, evaluate your primary manufacturing goal.

- If your primary focus is cost reduction in mass production: The significant decrease in machine downtime and frequency of tool changes delivers a compelling long-term financial advantage.

- If your primary focus is precision machining of abrasive materials: The ability of MPCVD tools to hold a sharp, consistent edge is essential for maintaining tight tolerances and achieving a high-quality surface finish.

- If your primary focus is overall process stability and reliability: The high reproducibility of MPCVD-coated tools ensures predictable performance from one tool to the next, simplifying quality control and process management.

Ultimately, integrating MPCVD diamond tools is a strategic decision to elevate your manufacturing capability by mastering the challenge of tool wear.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Extended Tool Life | Drastic reduction in tool replacements | High-volume production (automotive, aerospace) |

| Superior Cutting Efficiency | Excellent surface finish, less heat generation | Precision machining of non-ferrous materials |

| Reduced Operational Costs | Minimized machine downtime, higher throughput | Cost-sensitive mass production |

| High Process Reproducibility | Predictable, consistent tool performance | Applications requiring strict quality control |

Ready to transform your manufacturing process with superior tool performance?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and industrial facilities with advanced high-temperature furnace solutions, including the CVD systems essential for producing high-quality MPCVD diamond coatings. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique material processing requirements.

Contact us today to discuss how our expertise can help you achieve longer tool life, higher efficiency, and significant cost savings. #ContactForm

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What does CVD stand for and what is its primary function? Discover High-Purity Thin Film Deposition

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- How does the MPCVD process work to deposit diamond? A Guide to High-Purity Synthesis

- How does the ionization degree in MPCVD compare to other methods? Uncover Superior Film Quality and Speed

- What are the key features of MPCVD single crystal diamond deposition equipment? Precision Control for High-Quality Growth