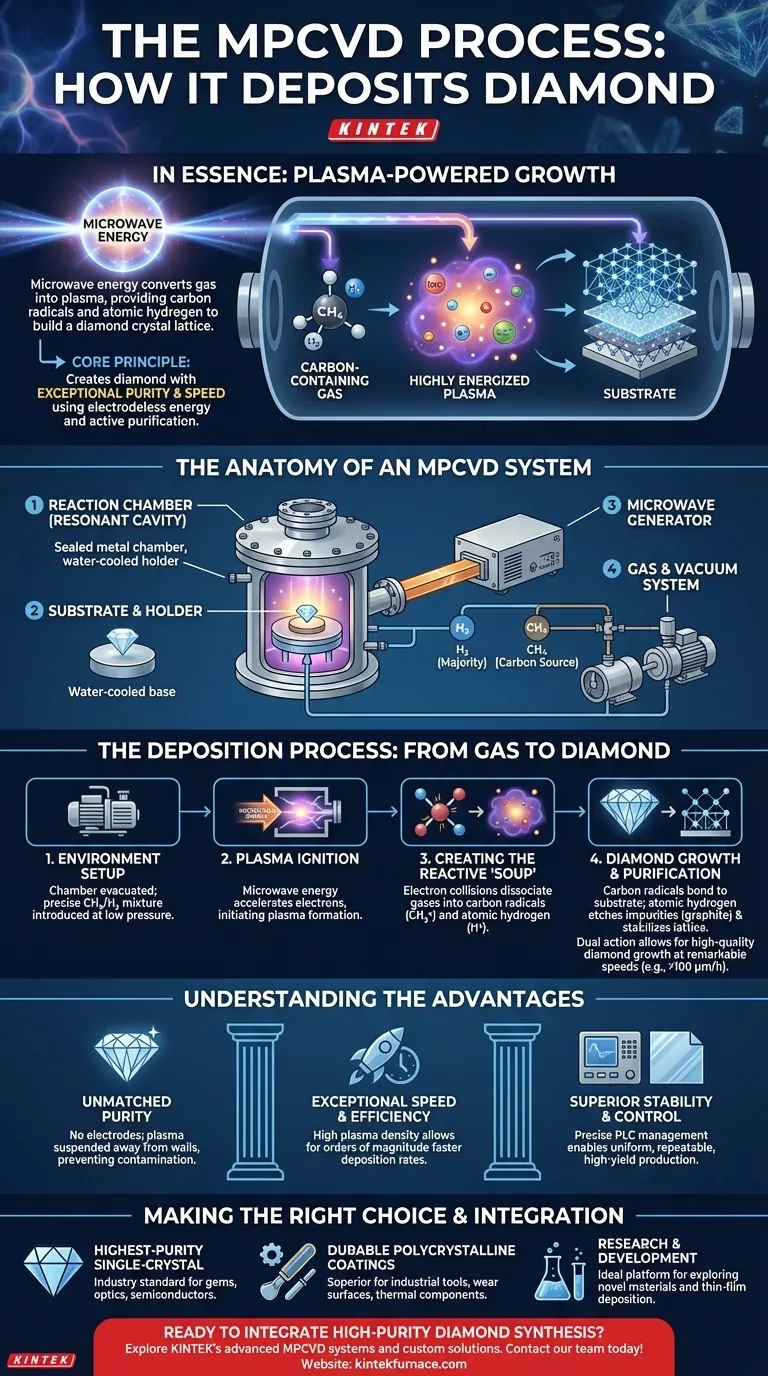

In essence, the Microwave Plasma Chemical Vapor Deposition (MPCVD) process grows diamond by using focused microwave energy to convert a carbon-containing gas into a highly energized plasma. Inside a vacuum chamber, this plasma provides the specific atomic ingredients—namely carbon radicals and atomic hydrogen—that are necessary to build a diamond crystal lattice layer by layer on a substrate, while simultaneously etching away any non-diamond impurities.

The core principle of MPCVD is not just creating diamond, but creating it with exceptional purity and speed. It achieves this by using clean, electrodeless microwave energy to generate a precisely controlled plasma that both deposits carbon atoms and actively purifies the growing diamond film.

The Anatomy of an MPCVD System

To understand the process, you must first understand the primary components of the equipment. Each part serves a critical function in creating the perfect conditions for diamond growth.

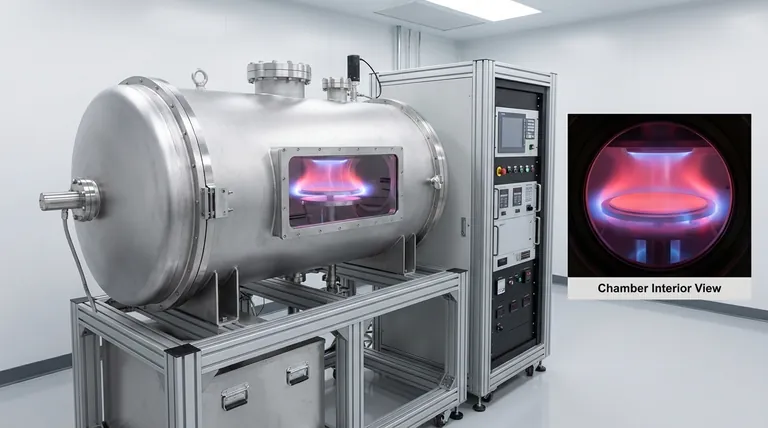

The Reaction Chamber and Substrate

The entire process takes place within a sealed, stainless steel reaction chamber, often called a resonant cavity. Inside, a substrate (a small diamond seed or another material) is placed on a water-cooled holder. This substrate is the foundation upon which the new diamond will grow.

The Microwave Generator

A high-power microwave generator, similar in principle to a microwave oven but far more powerful and precise, channels electromagnetic energy into the chamber. This energy is the engine that drives the entire reaction.

The Gas and Vacuum System

A sophisticated system of pumps first removes all air from the chamber to create an ultra-high vacuum. Then, a gas delivery system introduces a precise mixture of precursor gases—typically methane (CH₄) as the carbon source and an overwhelming majority of hydrogen (H₂).

The Deposition Process: From Gas to Diamond

With the system prepared, the deposition process unfolds in a precise, four-step sequence.

Step 1: Creating the Ideal Environment

The chamber is evacuated to low pressure, creating a pristine environment free of contaminants like nitrogen and oxygen. The carbon-source and hydrogen gas mixture is then introduced and maintained at a specific, low pressure.

Step 2: Plasma Ignition

The microwave generator is activated, flooding the chamber with electromagnetic energy. This energy doesn't heat the gas directly. Instead, it grabs free electrons in the gas and accelerates them, causing them to oscillate violently.

Step 3: Creating the Reactive "Soup"

These hyper-energized electrons collide with the methane and hydrogen gas molecules. These collisions are so forceful they rip the molecules apart, a process called dissociation, and knock off more electrons, creating a chain reaction of ionization. The result is a glowing ball of plasma—a superheated gas composed of ions, electrons, carbon radicals (like CH₃•), and critically, atomic hydrogen (H•).

Step 4: Diamond Growth and Purification

Carbon-containing radicals from the plasma descend and bond to the substrate surface, forming the diamond's crystal structure. Simultaneously, the abundant atomic hydrogen performs two critical functions:

- It preferentially etches away any carbon atoms that misalign into a non-diamond form (like graphite).

- It stabilizes the diamond lattice by terminating "dangling" bonds on the growth surface, preventing defects.

This dual action of deposition and purification is what allows MPCVD to produce exceptionally high-quality diamond at remarkable speeds, with some systems achieving growth rates over 100 µm/h.

Understanding the Advantages

MPCVD is widely regarded as a superior method for diamond synthesis for several key reasons that stem directly from its design.

Unmatched Purity

Because the plasma is generated by microwaves, there are no electrodes inside the chamber that could erode and contaminate the diamond. Furthermore, the plasma is suspended in the center of the chamber, preventing contact with the walls and further ensuring the purity of the final product.

Exceptional Speed and Efficiency

The high density of the plasma created by the microwaves leads to a supersaturated environment of reactive species. This allows for deposition rates that are orders of magnitude higher than many competing methods, making it commercially viable for producing both industrial and gem-quality diamonds.

Superior Stability and Control

Modern MPCVD systems use advanced PLC controls to precisely manage gas flow, pressure, and microwave power. The process is stable over a wide range of pressures and allows for uniform deposition over large areas, enabling repeatable, high-yield production runs.

Making the Right Choice for Your Goal

Understanding the fundamentals of MPCVD helps you decide where and how to apply this powerful technology.

- If your primary focus is creating the highest-purity single-crystal diamonds: MPCVD is the undisputed industry standard for applications in gem production, high-performance optics, and next-generation semiconductors.

- If your primary focus is producing durable polycrystalline coatings: MPCVD offers a superior combination of speed, quality, and control for coating industrial tools, wear surfaces, and thermal management components.

- If your primary focus is research and development: The stability and wide operational window of MPCVD make it an ideal platform for exploring novel materials and pushing the boundaries of thin-film deposition.

Ultimately, the MPCVD process represents a mastery of plasma physics, enabling the controlled creation of one of nature's most extreme materials.

Summary Table:

| Process Step | Key Action | Outcome |

|---|---|---|

| 1. Environment Setup | Chamber evacuated, precursor gases (CH₄/H₂) introduced. | Creates a pristine, low-pressure environment for reaction. |

| 2. Plasma Ignition | Microwave energy accelerates electrons in the gas. | Initiates the chain reaction leading to plasma formation. |

| 3. Gas Dissociation | Energetic electrons collide with and break apart gas molecules. | Creates a reactive plasma of carbon radicals and atomic hydrogen. |

| 4. Growth & Purification | Carbon radicals deposit on substrate; atomic hydrogen etches non-diamond carbon. | Builds a high-purity diamond crystal lattice layer by layer. |

Ready to Integrate High-Purity Diamond Synthesis into Your Work?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced MPCVD systems and other high-temperature furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements for growing single-crystal or polycrystalline diamond films.

Explore how our expertise can advance your research or production—contact our team today to discuss your project!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What does CVD stand for and what is its primary function? Discover High-Purity Thin Film Deposition

- What advantages do MPCVD diamond tools offer in industrial applications? Maximize Lifespan & Efficiency

- What is Microwave Plasma Chemical Vapor Deposition (MPCVD)? Unlock Ultra-Pure Diamond Synthesis

- What are the differences in film quality between PVD and CVD? Discover the Best Method for Your Application

- Can the reducing atmosphere be replaced with other gaseous mediums? Explore Advanced Surface Engineering Solutions