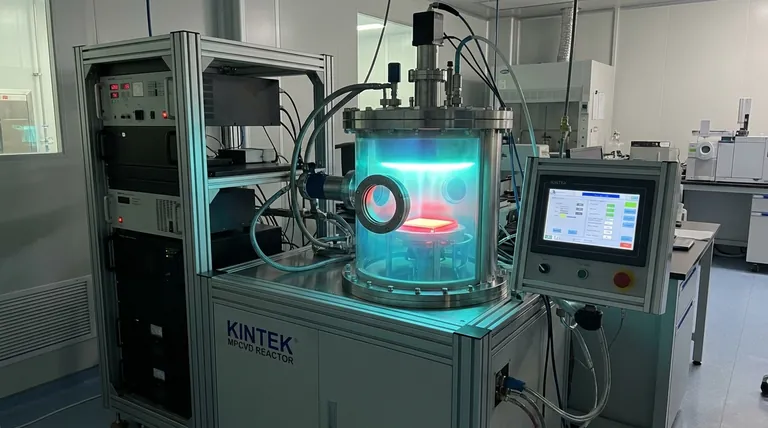

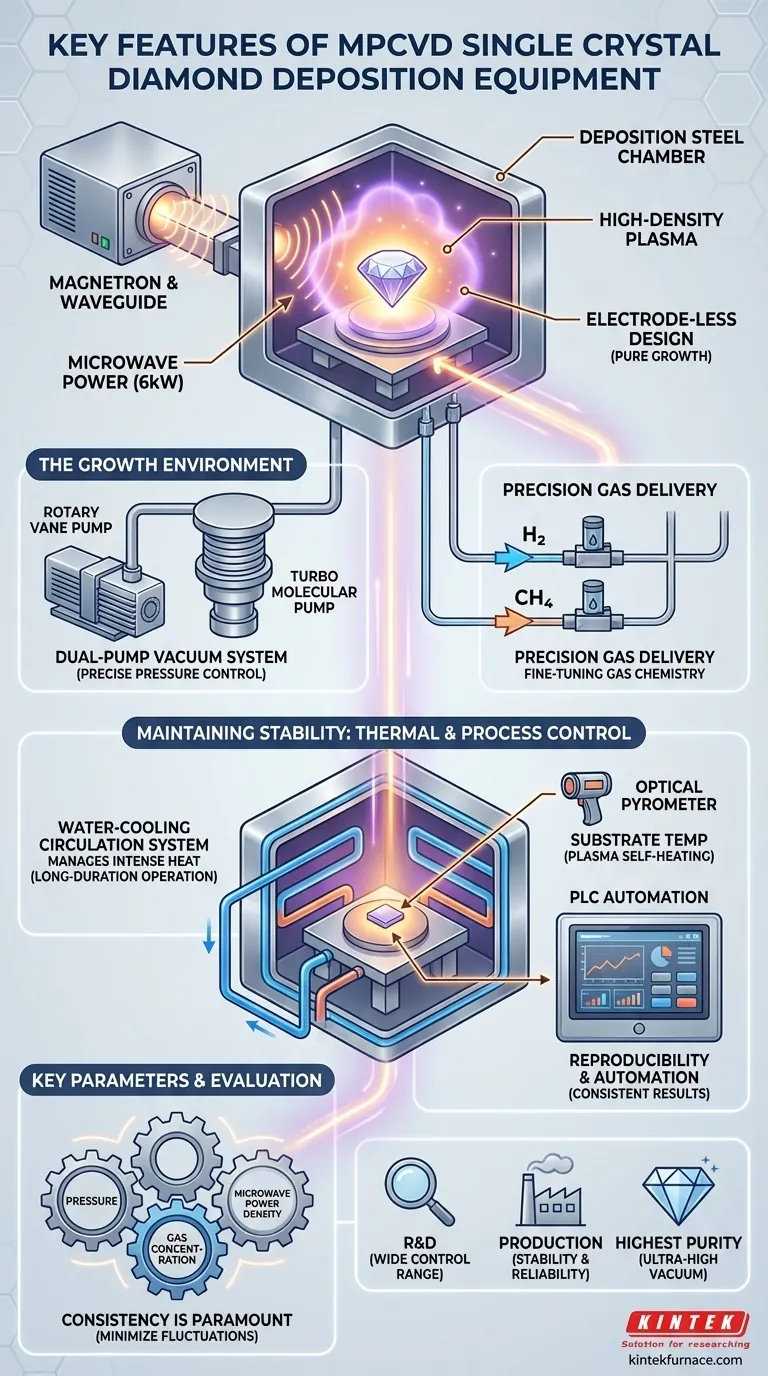

At its core, MPCVD single crystal diamond deposition equipment is a highly controlled system integrating a high-power microwave generator, a vacuum chamber, precision gas delivery, and advanced thermal management. Key features typically include a 6kW microwave plasma system within a stainless steel cavity, a water-cooled substrate stage and chamber, a dual-pump vacuum system for precise pressure control, and PLC-based automation for process reproducibility. These components work together to create the ideal conditions for diamond growth.

The design of MPCVD equipment is entirely focused on one objective: creating and maintaining an exceptionally pure and stable high-density plasma environment. Each component, from the vacuum pumps to the water cooling, works in concert to precisely control the temperature, pressure, and gas chemistry required for high-quality, reproducible diamond synthesis.

The Heart of the System: Microwave Plasma Generation

The process begins and ends with the quality of the plasma. The microwave system is engineered to generate a stable, dense, and pure plasma cloud, which is the foundational requirement for growing diamond.

The Microwave Generator and Waveguide

The system is powered by a microwave generator, typically a magnetron head, which produces the energy needed to ignite and sustain the plasma. This energy is channeled through a waveguide and into the deposition chamber.

Creating High-Density Plasma

Microwaves excite the process gases (like hydrogen and a carbon source), stripping electrons and creating a plasma state. The electromagnetic field causes violent oscillations and collisions, dramatically increasing the gas ionization to produce a high-density plasma rich in the atomic carbon required for diamond deposition.

Why an Electrode-less Design Matters

A key advantage of MPCVD is its electrode-less design. Unlike other methods, there are no internal filaments or electrodes that can degrade and contaminate the diamond. This enhances the purity of the final crystal and improves the overall energy efficiency of the system.

The Growth Environment: The Deposition Chamber

The chamber is the sealed environment where the reaction occurs. Its design is critical for maintaining purity and controlling the physical conditions of the growth process.

The Vacuum System

To ensure purity, the chamber must operate under a controlled vacuum. MPCVD systems use a two-part vacuum system: a rotary vane mechanical pump for initial roughing and a turbo molecular pump to achieve the high vacuum needed to remove contaminants. This allows for automatic and precise control of deposition pressure.

Precision Gas Delivery

The quality of the diamond is directly influenced by the chemistry of the plasma. The equipment includes a gas flow system that allows for the precise mixture and control of multiple gases, enabling fine-tuning of the growth recipe for specific outcomes.

Substrate and Chamber Construction

The deposition chamber itself is typically a stainless steel cavity with a dedicated substrate stage where the seed crystal is placed. Both the chamber walls and the stage are actively cooled to manage the intense heat generated by the plasma.

Maintaining Stability: Thermal and Process Control

Growing a single crystal of diamond can take hundreds of hours. Stability is not a feature; it is a fundamental necessity. The equipment's control systems are designed for reliable, long-duration operation.

The Critical Role of Cooling

High-power plasma generates immense heat. A robust cooling water circulation system is essential. This system cools both the substrate stage and the chamber walls, preventing overheating and ensuring the stable, long-term operation required for growing large, high-quality crystals.

Achieving Substrate Temperature

The substrate is heated to the optimal growth temperature directly by the microwave plasma itself in a process called plasma self-heating. This temperature is monitored by a non-contact optical pyrometer, allowing for precise and stable thermal control without introducing potential contaminants.

Automation and Reproducibility

Modern MPCVD equipment features PLC (Programmable Logic Controller) automation managed through a touch screen interface. This allows operators to save and load specific process recipes, ensuring that growth parameters are identical from run to run. This automation is the key to achieving reproducible sample quality.

Understanding the Key Parameters

While the equipment provides the necessary tools, the quality of the diamond ultimately depends on the skill of the operator in balancing several critical process variables.

The Interplay of Process Variables

The final diamond quality is a result of a complex interplay between pressure, gas concentration, and microwave power density. The MPCVD system gives the operator fine control over these inputs, but achieving optimal results requires careful experimentation and recipe development.

Consistency is a Prerequisite

For high-quality single-crystal growth, the stability of every parameter is paramount. Even minor fluctuations in microwave power, gas pressure, or temperature can introduce defects into the crystal lattice, degrading its quality. The equipment's primary job is to minimize these fluctuations.

How to Evaluate MPCVD Equipment for Your Goal

When selecting a system, your specific application should guide your priorities.

- If your primary focus is research and development: You need a system with the widest possible range of precise control over all parameters (gas flow, pressure, power) to explore different growth recipes.

- If your primary focus is high-volume production: You need a system built for stability, reliability, and long-duration runs, with robust automation and cooling to ensure reproducibility.

- If your primary focus is growing the highest-purity crystals: You must prioritize features that minimize contamination, such as an ultra-high vacuum system and a proven electrode-less plasma source design.

Understanding how these core features enable precise environmental control is the key to successfully selecting and operating MPCVD equipment.

Summary Table:

| Key Feature | Function | Benefit |

|---|---|---|

| Microwave Plasma System (6kW) | Generates high-density, electrode-less plasma | Pure, contaminant-free diamond growth |

| Dual-Pump Vacuum System | Achieves and maintains high vacuum | Removes contaminants, ensures process purity |

| Water-Cooling System | Manages heat from plasma | Enables stable, long-duration operation |

| PLC Automation | Controls pressure, temperature, gas flow | Guarantees recipe reproducibility and consistency |

Ready to achieve unparalleled precision in your single crystal diamond research or production? At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced MPCVD solutions tailored to your unique needs. Whether you require deep customization for R&D exploration or a robust system for high-volume production, our expertise ensures you get the reliable, high-purity results you demand. Contact our experts today to discuss how our MPCVD equipment can accelerate your innovation!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- Can the reducing atmosphere be replaced with other gaseous mediums? Explore Advanced Surface Engineering Solutions

- How does the ionization degree in MPCVD compare to other methods? Uncover Superior Film Quality and Speed

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What advantages do MPCVD diamond tools offer in industrial applications? Maximize Lifespan & Efficiency