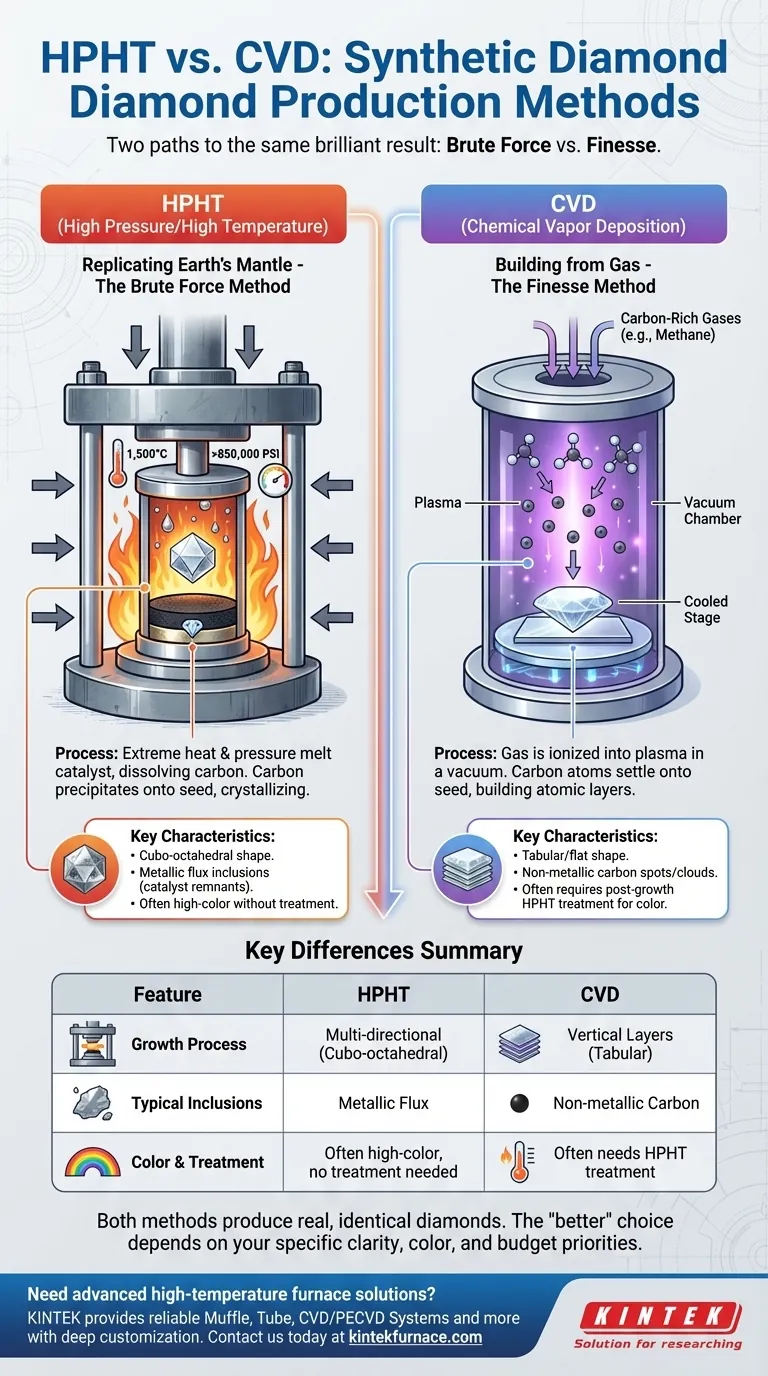

The two primary methods for creating lab-grown diamonds are High Pressure/High Temperature (HPHT) and Chemical Vapor Deposition (CVD). While both yield a gemstone that is physically, chemically, and optically identical to a mined diamond, they achieve this result through fundamentally different processes. One method brutally mimics the forces of nature, while the other delicately builds the diamond atom by atom.

The core difference lies in the approach: HPHT is a "brute force" method that simulates the earth's natural diamond-forming conditions. In contrast, CVD is a "finesse" method that grows a diamond in layers from a carbon gas, much like atomic 3D printing.

The HPHT Method: Replicating the Earth's Mantle

The High Pressure/High Temperature method was the first commercially successful technique for diamond synthesis. Its goal is to recreate the extreme environment deep within the Earth where natural diamonds are formed.

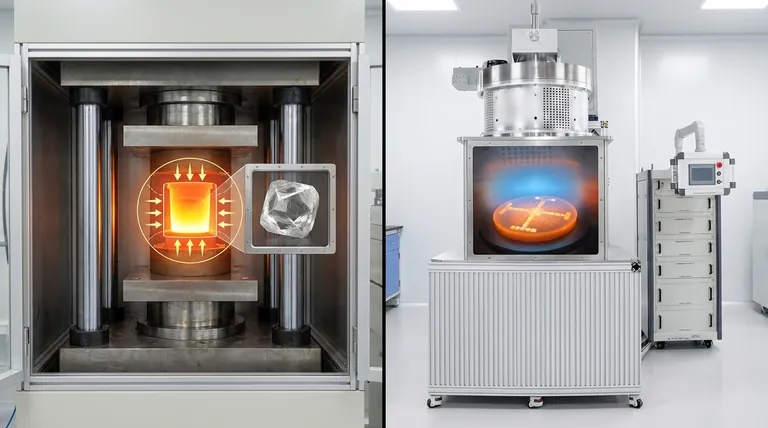

How It Works: A Geological Pressure Cooker

At its core, the HPHT process places a tiny diamond seed crystal into a chamber along with a source of pure carbon, typically graphite.

This chamber also contains a metal catalyst, which is crucial to the process. The entire capsule is then subjected to immense pressure (over 850,000 pounds per square inch) and extreme heat (around 1,500°C).

Under these conditions, the metal catalyst melts and dissolves the carbon source. This carbon solution then precipitates onto the cooler diamond seed, crystallizing in its diamond structure and growing the crystal over time.

Characteristics of HPHT Diamonds

HPHT diamonds grow in a cubo-octahedral shape, influenced by the pressure from all sides. A key identifying feature can be the presence of metallic flux inclusions—tiny remnants of the metal catalyst trapped during growth.

While early HPHT diamonds often had a yellowish or brownish tint due to nitrogen exposure, modern techniques have advanced significantly. The process is now capable of producing high-color (colorless and near-colorless) diamonds directly and is also used to improve the color of some natural and CVD-grown diamonds.

The CVD Method: Building from Gas

Chemical Vapor Deposition is a newer technique that approaches diamond growth from a completely different angle. Instead of simulating geological force, it builds a diamond in a highly controlled, low-pressure environment.

How It Works: Atomic Construction

The CVD process begins by placing a thin slice of a diamond seed into a vacuum chamber.

This chamber is then filled with carbon-rich gases, like methane. These gases are heated to an extreme temperature, forming a plasma that breaks the gas molecules apart and liberates the carbon atoms.

These free carbon atoms are then drawn down to the cooler diamond seed plate, where they attach themselves and build upon the crystal lattice. The diamond grows vertically, layer by layer, over several weeks.

Characteristics of CVD Diamonds

Because they grow in one primary direction, raw CVD diamonds have a distinct tabular or flat shape.

Common identifying characteristics include pinpoint carbon spots or dark "clouds" of graphite, which can form if the growth process is not perfectly controlled. However, top-tier producers can create exceptionally clean CVD stones.

Many CVD diamonds require a post-growth treatment—often HPHT—to improve their color by removing lingering brown or gray tints. This is a standard, permanent, and fully disclosed part of the production process for many stones.

Understanding the Key Differences

Neither method is inherently superior, but their distinct processes result in different growth characteristics and potential trade-offs.

Growth Process and Shape

HPHT applies pressure from all sides, creating a multi-directional growth pattern and a crystal shape similar to a natural diamond octahedron. CVD builds the diamond in vertical layers, resulting in a flat, tabular raw crystal.

Inclusions and Clarity

The most common inclusions in HPHT diamonds are metallic, remnants of the catalyst. In CVD diamonds, they are typically non-metallic carbon spots or lines. Both methods are capable of producing flawless diamonds, but the type of potential flaw is a direct result of the growth method.

Color and Treatments

Modern HPHT processes can consistently produce high-color diamonds with no further treatment. CVD diamonds, on the other hand, often require a secondary HPHT treatment to permanently remove color tints and achieve a colorless grade. This is a critical distinction for understanding a diamond's history.

Making the Right Choice for Your Goal

The "better" method is the one that produces the best final gemstone for your specific criteria. The quality of the individual producer is far more important than the method itself.

- If your primary focus is finding a high-clarity stone with no metallic inclusions: A high-quality CVD diamond might be preferable, but always verify if it has undergone post-growth color treatment.

- If your primary focus is a high-color diamond that likely required no post-growth treatment: An HPHT diamond from a modern, reputable producer is an excellent and straightforward choice.

- If your primary focus is value: Both methods produce diamonds at competitive prices, and the final cost is driven by the traditional 4Cs (cut, color, clarity, carat), not the growth method.

Ultimately, both HPHT and CVD are remarkable technologies that produce real diamonds, and the quality of the specific gemstone is far more important than its method of origin.

Summary Table:

| Method | Growth Process | Typical Inclusions | Color Characteristics |

|---|---|---|---|

| HPHT | High pressure and temperature, multi-directional growth | Metallic flux inclusions | Often high-color, may require no treatment |

| CVD | Chemical vapor deposition, vertical layer-by-layer growth | Non-metallic carbon spots or graphite clouds | Often requires HPHT treatment for color improvement |

Need advanced high-temperature furnace solutions for your diamond synthesis or lab work? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental requirements. Contact us today to enhance your production efficiency and achieve superior results!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth

- What is the relationship between diamond growth rate and quality in the MPCVD method? Balancing Speed and Purity for Your Application

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis