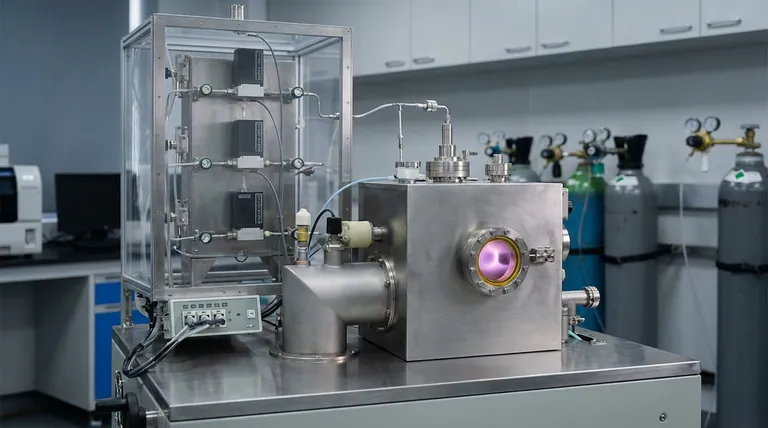

A Plasma Assisted Chemical Vapor Deposition (PACVD) system prepares friction-reducing layers by utilizing a plasma glow discharge to initiate the decomposition of specific gaseous precursors.

This high-energy process breaks down compounds like Tetramethylsilane (Si(CH3)4) and Acetylene (C2H2) within a vacuum chamber. The resulting chemical reaction deposits a silicon-doped diamond-like carbon (DLC:Si) film onto a base layer (such as CrAlSiN), creating a composite surface with excellent self-lubricating properties.

Core Takeaway PACVD distinguishes itself by using plasma energy rather than just thermal energy to drive chemical reactions. This allows for the precise synthesis of advanced, low-friction materials like silicon-doped diamond-like carbon (DLC:Si) that significantly enhance tool performance.

The Deposition Mechanism

Plasma Glow Discharge

The core of the PACVD system is the generation of a plasma glow discharge.

This discharge provides the necessary energy to initiate chemical reactions that might otherwise require excessive heat. It acts as the catalyst for breaking down the chemical bonds of the source gases.

Precursor Decomposition

The system utilizes specific gaseous precursors to build the friction-reducing layer.

According to the primary technical data, Tetramethylsilane and Acetylene are introduced into the chamber. The plasma environment decomposes these gases into their reactive atomic constituents.

Formation of DLC:Si Films

The decomposed elements react and condense onto the substrate surface.

This process results in the growth of silicon-doped diamond-like carbon (DLC:Si) films. When applied over nitride layers like CrAlSiN, this topcoat provides the critical "self-lubricating" characteristic and a very low coefficient of friction.

The General Process Flow

Transport and Introduction

Before the plasma activates, the precursor gases must be transported into the reaction chamber.

The reactants are moved to the substrate surface via convection or diffusion within a controlled vacuum environment. This ensures a uniform distribution of the gas mixture before the reaction begins.

Surface Adsorption and Reaction

Once the plasma generates reactive species, they diffuse through the boundary layer.

These species adsorb onto the substrate surface. Here, heterogeneous reactions occur, transforming the gaseous reactants into a solid, cohesive film on the tool or component.

Desorption and Exhaust

As the solid coating forms, the chemical reaction simultaneously generates volatile by-products.

These by-products must detach (desorb) from the surface to prevent contamination. The system’s exhaust mechanism continuously removes these waste gases from the reaction chamber to maintain purity.

Understanding the Trade-offs

Process Complexity

PACVD is more complex than simple thermal treatments.

It requires precise control over vacuum pressure, gas flow rates, and plasma power. Any deviation in these variables can affect the stoichiometry of the DLC:Si layer, potentially compromising its friction-reducing capabilities.

Environmental Requirements

The process dictates a strict vacuum environment.

Unlike simple dip-coatings, the substrate must be held in a vacuum chamber where high-temperature gaseous materials and plasma can be managed safely. This limits the size and throughput of the batch based on the chamber dimensions.

Making the Right Choice for Your Project

To determine if PACVD is the correct solution for your surface engineering needs, consider your specific performance targets:

- If your primary focus is extreme friction reduction: Prioritize PACVD for its ability to deposit silicon-doped diamond-like carbon (DLC:Si), which offers superior self-lubricating properties.

- If your primary focus is coating adhesion on complex geometries: Ensure your substrate material (e.g., nitrides like CrAlSiN) is compatible with the PACVD process to guarantee a robust composite structure.

By leveraging the high-energy efficiency of plasma discharge, you can achieve surfaces that offer both durability and exceptional lubricity.

Summary Table:

| Feature | PACVD Process Detail |

|---|---|

| Energy Source | Plasma Glow Discharge (Electric Field) |

| Key Precursors | Tetramethylsilane (Si(CH3)4) & Acetylene (C2H2) |

| Resulting Layer | Silicon-doped Diamond-Like Carbon (DLC:Si) |

| Core Mechanism | Chemical vapor decomposition via plasma energy |

| Primary Benefit | Self-lubricating surface with low friction coefficient |

| Substrate Compatibility | Works with base layers like CrAlSiN nitrides |

Elevate Your Tooling Performance with KINTEK

Unlock the full potential of advanced surface engineering. Backed by expert R&D and manufacturing, KINTEK offers high-performance CVD and PACVD systems, alongside a comprehensive range of muffle, tube, rotary, and vacuum high-temp furnaces—all customizable for your unique material science needs.

Whether you are developing self-lubricating DLC films or high-durability composite coatings, our technical experts are ready to design the perfect thermal and plasma solution for your laboratory.

Contact KINTEK Today to Optimize Your Coating Process

References

- Sergey N. Grigoriev, Anna A. Okunkova. Increasing the Wear Resistance of Stamping Tools for Coordinate Punching of Sheet Steel Using CrAlSiN and DLC:Si Coatings. DOI: 10.3390/technologies13010030

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

People Also Ask

- What is Inductively Coupled Plasma Chemical Vapor Deposition (ICP-CVD)? Achieve Superior Low-Temperature Thin Films

- What are the main technologies for thin film deposition? Choose PVD, CVD, or PECVD for Your Needs

- How can film properties be tuned in PECVD? Master Key Parameters for Optimal Film Control

- What are the hardware specifications for PECVD systems? Key Components for Precise Thin Film Deposition

- How does the PECVD system handle passivation layers in PERC solar cells? Boost Efficiency with Precision Deposition

- What happens during the chemical reactions and deposition phase of PECVD? Master Low-Temperature Thin Film Deposition

- What are the applications of plasma enhanced chemical vapor deposition? Key Uses in Electronics, Optics & Materials

- What gases are supplied in the PECVD gas supply system? Optimize Your Thin Film Deposition Process