At its core, a Plasma-Enhanced Chemical Vapor Deposition (PECVD) gas supply system provides a controlled mixture of gases that are essential for both depositing thin films and cleaning the reaction chamber. Common gases include precursors like Silane (SiH4), reactants like Ammonia (NH3) and Nitrous Oxide (N2O), inert carrier gases like Argon (Ar) and Nitrogen (N2), and cleaning agents like Carbon Tetrafluoride (CF4) mixed with Oxygen (O2).

The function of a PECVD gas supply is not merely to pipe in chemicals, but to precisely meter and mix different categories of gas—precursors, reactants, and etchants—that serve as the fundamental building blocks and maintenance tools for creating high-quality thin films.

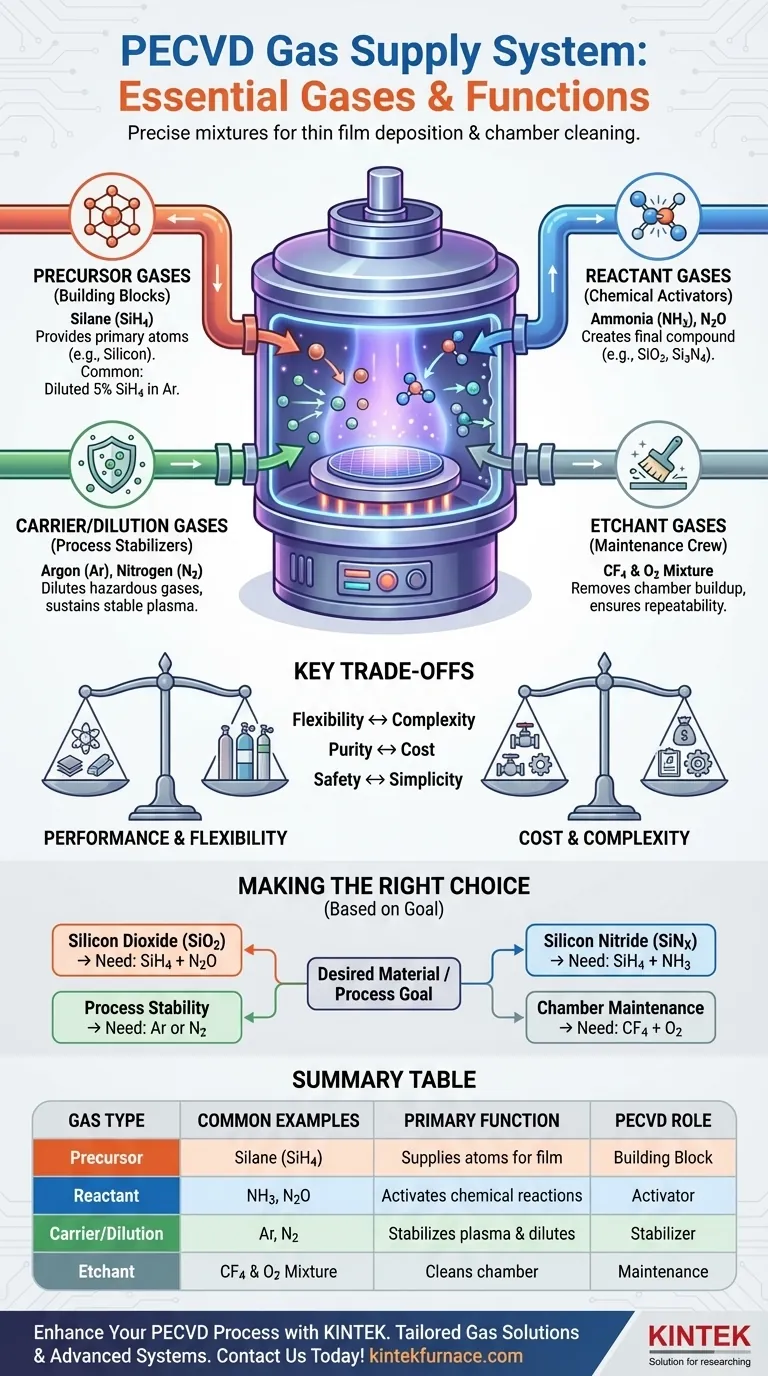

The Functional Roles of PECVD Gases

To truly understand the gas supply, you must think in terms of function. Each gas serves a distinct purpose in the deposition or cleaning process, and they are almost always used in combination.

Precursor Gases: The Film's Building Blocks

A precursor gas is the primary source of the atoms you intend to deposit onto your substrate. These gases are selected to break down easily in the plasma.

The most common precursor is Silane (SiH4), which is the source of silicon (Si) for depositing silicon-based films like silicon dioxide and silicon nitride. For safety and process control, it is often supplied diluted in a carrier gas, such as 5% SiH4 in Argon.

Reactant Gases: The Chemical Activators

Reactant gases are introduced alongside the precursor to create the final, desired chemical compound for the film. They react with the dissociated precursor in the plasma environment.

Common reactants include:

- Nitrous Oxide (N2O) or Oxygen (O2) to provide the oxygen for Silicon Dioxide (SiO₂) films.

- Ammonia (NH3) to provide the nitrogen for Silicon Nitride (Si₃N₄) films.

Carrier and Dilution Gases: The Process Stabilizers

Inert gases play a crucial supporting role. They do not become part of the final film but are vital for controlling the process.

Their two main functions are dilution and plasma stability. Gases like Argon (Ar) and Nitrogen (N2) are used to dilute hazardous or highly reactive precursors like SiH4. This makes the process safer and allows for finer control over the reaction rate. These gases also help sustain a stable and uniform plasma within the chamber.

Etchant Gases: The Maintenance Crew

Over time, the desired film material will coat not only the substrate but also the internal walls of the PECVD chamber. This buildup must be removed to prevent contamination and ensure process repeatability.

A dedicated mixture of gases, such as Carbon Tetrafluoride (CF4) and Oxygen (O2), is used for in-situ plasma cleaning. This gas mixture forms a reactive plasma that etches away the unwanted deposits, effectively resetting the chamber for the next run.

Understanding the Trade-offs

The choice and configuration of a gas supply system involve critical trade-offs between performance, safety, and cost.

Process Flexibility vs. System Complexity

A system designed to handle a wide array of precursors, reactants, and etchants offers tremendous process flexibility. However, each additional gas line adds significant complexity, cost, and potential points of failure through its own mass flow controller, valves, and plumbing.

Gas Purity vs. Material Cost

High-purity gases are essential for creating high-quality, defect-free electronic and optical films. However, increasing purity from 99.99% to 99.9999% can increase the cost exponentially. Using lower-purity gas is cheaper but risks introducing contaminants that degrade film performance.

Safety Protocols vs. Operational Simplicity

Many essential PECVD gases are hazardous. Silane (SiH4) is pyrophoric (ignites spontaneously in air), and Ammonia (NH3) is toxic and corrosive. Handling these gases requires sophisticated safety interlocks, gas detection systems, and emergency protocols, adding significant overhead compared to working only with inert gases like Argon.

Making the Right Choice for Your Goal

Your choice of gases is determined entirely by the material you intend to deposit and the processes you need to run.

- If your primary focus is depositing Silicon Dioxide (SiO₂): You will need a silicon precursor like Silane (SiH4) and an oxygen source like Nitrous Oxide (N2O).

- If your primary focus is depositing Silicon Nitride (SiNₓ): You will need a silicon precursor (SiH4) and a nitrogen source, typically Ammonia (NH3).

- If your primary focus is process control and stability: You will use inert carrier gases like Argon (Ar) or Nitrogen (N2) to manage reactant concentrations and sustain the plasma.

- If your primary focus is chamber maintenance: You require a dedicated line for etchant gases, such as a mixture of Carbon Tetrafluoride (CF4) and Oxygen (O2).

By understanding these distinct gas categories, you can effectively translate your desired film properties into a specific and controllable gas recipe for your PECVD system.

Summary Table:

| Gas Type | Common Examples | Primary Function |

|---|---|---|

| Precursor | Silane (SiH4) | Supplies atoms for film deposition (e.g., silicon) |

| Reactant | Ammonia (NH3), Nitrous Oxide (N2O) | Activates chemical reactions to form films (e.g., silicon nitride) |

| Carrier/Dilution | Argon (Ar), Nitrogen (N2) | Stabilizes plasma and dilutes reactive gases |

| Etchant | CF4 and O2 mixture | Cleans chamber by removing unwanted deposits |

Ready to enhance your PECVD process with tailored gas solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, whether you're working on semiconductor devices, optical coatings, or other thin film applications. Contact us today to discuss how our expertise can optimize your lab's efficiency and film quality!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the advantages of PECVD? Enable Low-Temp, High-Quality Film Deposition

- Is PECVD directional? Understanding Its Non-Line-of-Sight Advantage for Complex Coatings

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition