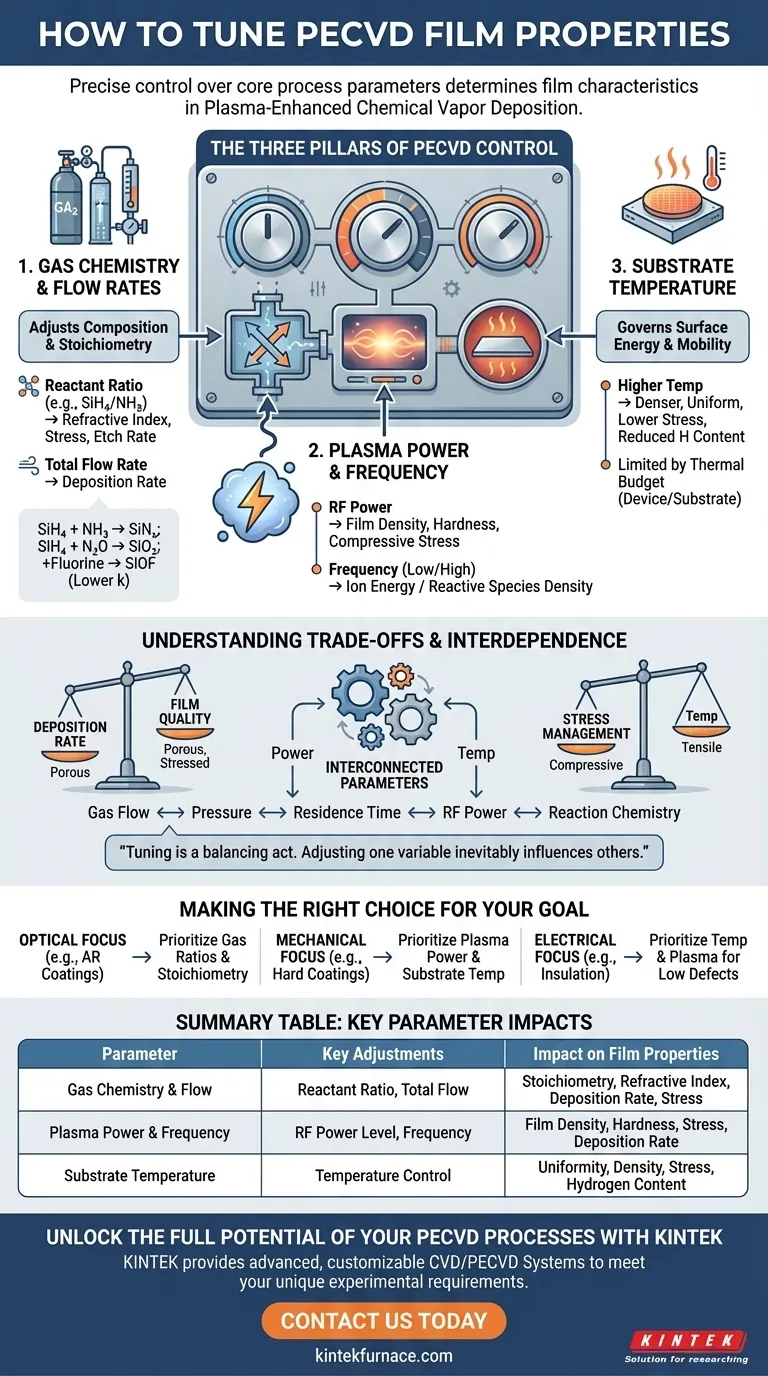

In Plasma-Enhanced Chemical Vapor Deposition (PECVD), film properties are tuned by precisely adjusting the core process parameters. The primary levers you can control are the reactant gas composition and flow rates, the plasma power and frequency, and the substrate temperature, each of which systematically alters the resulting film's chemical, optical, and mechanical characteristics.

The key to mastering PECVD is understanding that its parameters are not independent dials. Tuning a film for a specific application is a balancing act, where adjusting one variable—like gas flow—inevitably influences others and requires a holistic approach to process control.

The Three Pillars of PECVD Control

Achieving a target film property, whether it's a specific refractive index or a desired level of stress, depends on manipulating three fundamental aspects of the deposition environment.

1. Gas Chemistry and Flow Rates

The gases you introduce into the chamber are the literal building blocks of your film. Their composition and flow directly dictate the film's stoichiometry and deposition rate.

### Defining the Film's Composition

The choice of precursor gases determines the fundamental material being deposited. For example, using silane (SiH₄) and ammonia (NH₃) will produce silicon nitride (SiNₓ), while using silane and nitrous oxide (N₂O) produces silicon dioxide (SiO₂).

### Tuning Stoichiometry

By adjusting the ratio of the reactant gases, you can fine-tune the film's stoichiometry. In a silicon nitride deposition, changing the SiH₄/NH₃ ratio directly alters the silicon-to-nitrogen content, which in turn modifies the film's refractive index, stress, and etch rate.

### Expanding Material Possibilities

You can introduce additional gases to create more complex films. Adding a fluorine-containing gas, for instance, enables the deposition of fluorinated silicon dioxide (SiOF), which has a lower dielectric constant than standard SiO₂.

### Controlling Deposition Rate

Higher total gas flow rates generally increase the deposition rate by supplying more precursor material to the reaction zone. However, this must be balanced, as excessively high flow can reduce the time precursors spend in the plasma, leading to inefficient chemical reactions.

2. Plasma Power and Frequency

The plasma is the engine of the PECVD process, providing the energy needed to break down reactant gases into reactive species. Controlling the plasma is critical for tuning film density and stress.

### Impact of Plasma Power

Increasing the RF power energizes the plasma, leading to a higher degree of gas dissociation and increased ion bombardment of the substrate. This typically results in a denser, harder film. However, excessive power can increase compressive stress and may cause substrate damage.

### The Role of Frequency

The RF frequency used to generate the plasma also plays a role. Lower frequencies tend to increase ion energy, promoting film densification, while higher frequencies can produce a higher density of reactive species, which can increase the deposition rate.

3. Substrate Temperature

Temperature governs the energy available at the film's growth surface, influencing how deposited atoms arrange themselves.

### Enhancing Film Quality

Higher substrate temperatures provide more energy to the atoms landing on the surface. This increased surface mobility allows them to find more stable bonding sites, resulting in a denser, more uniform film with lower intrinsic stress and reduced hydrogen content.

### Managing Thermal Constraints

The maximum usable temperature is often limited by the thermal budget of the substrate or the device already fabricated on it. PECVD's primary advantage is its ability to produce high-quality films at lower temperatures than conventional CVD.

Understanding the Trade-offs

Process optimization is rarely about maximizing a single parameter. More often, it involves navigating competing factors to find an acceptable balance.

### Deposition Rate vs. Film Quality

A common trade-off exists between deposition speed and film quality. While high power and flow rates can increase throughput, they can also lead to more porous, less uniform, or highly stressed films. High-quality optical or electronic films often require slower, more controlled deposition conditions.

### Stress Management

Film stress (either compressive or tensile) is a critical property that can cause film cracking, delamination, or wafer bowing. Stress is influenced by nearly all parameters: higher plasma power increases compressive stress due to ion bombardment, while thermal mismatch and gas chemistry also play significant roles. Managing stress requires careful, multi-parameter optimization.

### The Interdependence of Parameters

It is crucial to recognize that these parameters are interconnected. Changing the gas flow rate alters the pressure and the residence time of molecules in the plasma, which may require an adjustment in RF power to maintain the desired reaction chemistry. Effective process development involves co-optimizing these variables.

Making the Right Choice for Your Goal

Your optimization strategy should be driven by the most critical property for your application.

- If your primary focus is optical properties (e.g., anti-reflection coatings): Concentrate on meticulously controlling the gas ratios to tune the film's stoichiometry and achieve the target refractive index.

- If your primary focus is mechanical properties (e.g., hard coatings): Prioritize optimizing plasma power and substrate temperature to increase film density and hardness while managing intrinsic stress.

- If your primary focus is electrical properties (e.g., insulation): Focus on temperature and plasma conditions to minimize hydrogen content and create a dense, pure film with a low defect density.

Ultimately, PECVD is a powerful and versatile tool that offers exceptional control once you understand the interplay between its core parameters.

Summary Table:

| Parameter | Key Adjustments | Impact on Film Properties |

|---|---|---|

| Gas Chemistry and Flow Rates | Ratio of reactant gases, total flow rates | Alters stoichiometry, refractive index, deposition rate, and stress |

| Plasma Power and Frequency | RF power level, frequency settings | Influences film density, hardness, stress, and deposition rate |

| Substrate Temperature | Temperature control during deposition | Affects film uniformity, density, stress, and hydrogen content |

Unlock the Full Potential of Your PECVD Processes with KINTEK

Struggling to achieve the precise film properties your experiments demand? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including our specialized CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether you're tuning optical, mechanical, or electrical properties.

Ready to optimize your PECVD results? Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and success!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency