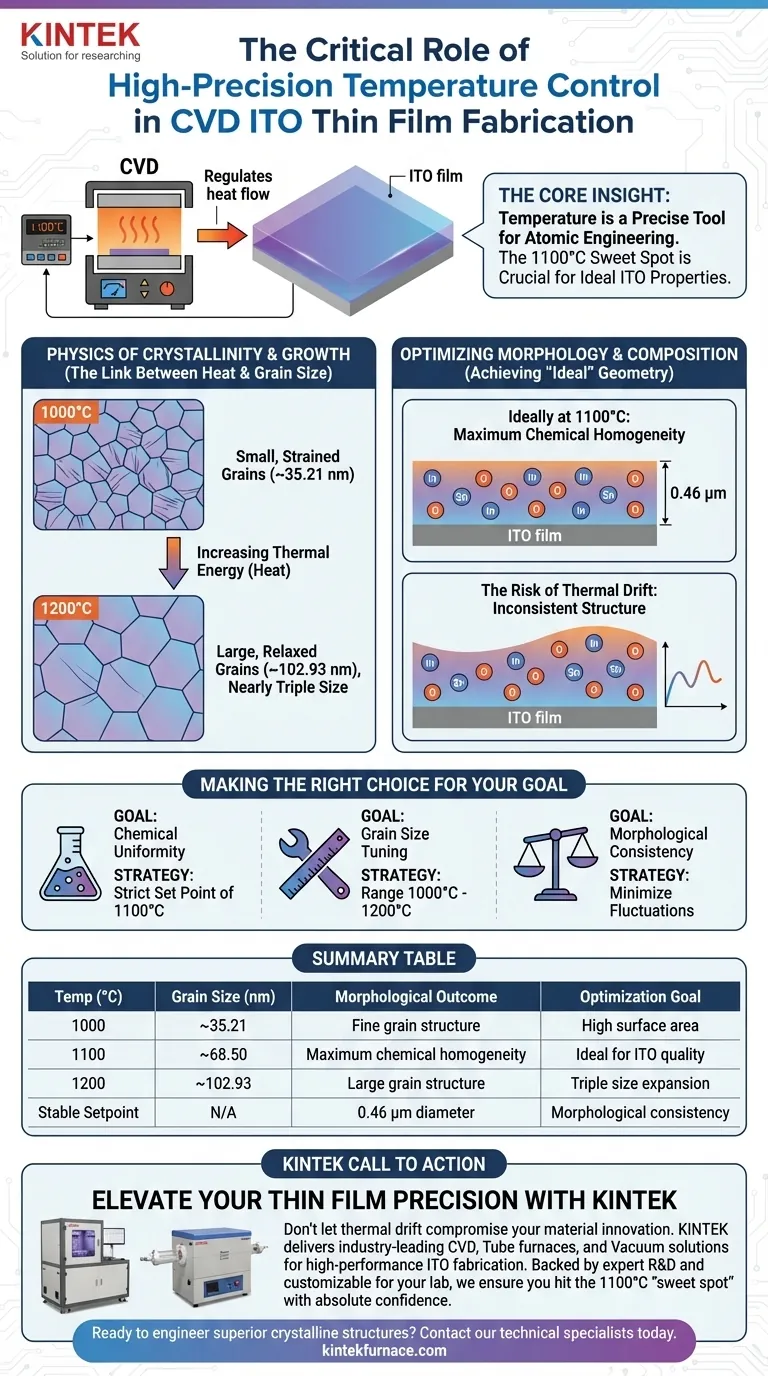

High-precision temperature control is the definitive variable for determining the structural quality of Indium Tin Oxide (ITO) thin films during Chemical Vapor Deposition (CVD).

Because the deposition temperature directly dictates the energy available for atomic arrangement, it governs critical properties such as grain size, lattice strain, and chemical uniformity. Without tight regulation, slight thermal deviations result in inconsistent film morphology, compromising the material's final performance.

The Core Insight Temperature in CVD is not merely an environmental condition; it is a precise tool for engineering microstructure. For ITO films, adhering to a specific optimal temperature—typically 1100°C—is the only way to simultaneously achieve ideal diameter uniformity, maximum chemical homogeneity, and the targeted grain size.

The Physics of Crystallinity and Growth

The Link Between Heat and Grain Size

In the CVD process, thermal energy drives the nucleation and growth of crystal grains.

Data indicates a sensitive correlation between temperature and grain magnitude. Increasing the process temperature from 1000°C to 1200°C can cause grain sizes to nearly triple, expanding from approximately 35.21 nm to 102.93 nm.

Managing Lattice Strain

This growth is not just cosmetic; it reflects the internal stress of the material.

Precise thermal regulation allows the lattice to relax and form a more perfect structure. By controlling the heat, you effectively manage lattice strain, ensuring the crystalline structure is stable rather than chaotic or defective.

Optimizing Morphology and Composition

Achieving the "Ideal" Geometry

Beyond simple grain size, the overall morphology of the film relies on thermal stability.

The goal is often to create a uniform structure, such as a consistent diameter of 0.46 micrometers. High-precision controllers ensure the furnace holds the exact conditions necessary for this specific geometry to form across the entire substrate.

The 1100°C Sweet Spot

While higher temperatures generally increase grain size, there is an optimal point for chemical composition.

Research identifies 1100°C as the critical threshold for ITO fabrication. At this specific temperature, the material achieves its highest chemical composition uniformity. Deviating from this set point risks introducing structural heterogeneity.

Understanding the Trade-offs

Temperature vs. Other Variables

While temperature is paramount for crystallinity, it cannot fix issues caused by poor vacuum or pressure control.

CVD relies on the gas phase mixing of reactants to ensure purity. Even with perfect temperature control, if the background pressure is not maintained (e.g., removing impurities via high vacuum before deposition), the purity of the film will suffer.

The Risk of Thermal Drift

Inaccurate controllers lead to thermal drift—gradual fluctuations in temperature over time.

Because the window for optimal ITO properties is specific (centering on 1100°C), drift can lead to a gradient of properties across the film. One section may have large, relaxed grains (103 nm), while another retains smaller, strained grains (35 nm), resulting in unpredictable device performance.

Making the Right Choice for Your Goal

To leverage temperature control effectively in your ITO fabrication process, align your thermal strategy with your specific material requirements:

- If your primary focus is Chemical Uniformity: Calibrate your controllers to maintain a strict set point of 1100°C to maximize compositional homogeneity.

- If your primary focus is Grain Size Tuning: Utilize the 1000°C to 1200°C range to dynamically adjust grain size between ~35 nm and ~103 nm based on your application's conductivity or transparency needs.

- If your primary focus is Morphological Consistency: Ensure your heating system minimizes fluctuations to achieve uniform structural diameters, such as the ideal 0.46 micrometers.

Precision in temperature control transforms CVD from a simple coating process into a method for exact atomic engineering.

Summary Table:

| Temperature (°C) | Grain Size (nm) | Morphological Outcome | Optimization Goal |

|---|---|---|---|

| 1000 | ~35.21 | Fine grain structure | High surface area |

| 1100 | ~68.50 | Maximum chemical homogeneity | Ideal for ITO quality |

| 1200 | ~102.93 | Large grain structure | Triple size expansion |

| Stable Setpoint | N/A | 0.46 μm diameter | Morphological consistency |

Elevate Your Thin Film Precision with KINTEK

Don't let thermal drift compromise your material innovation. KINTEK provides industry-leading CVD systems, Tube furnaces, and Vacuum solutions designed to deliver the rigorous temperature stability required for high-performance ITO fabrication.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique laboratory needs—ensuring you hit the 1100°C 'sweet spot' with absolute confidence every time.

Ready to engineer superior crystalline structures?

Contact our technical specialists today to find the perfect thermal solution for your research.

Visual Guide

References

- Muchammad Yunus, Azianty Saroni. Effect of Deposition Temperature on The Structural and Crystallinity Properties of Self-Catalyzed Growth Indium Tin Oxide (ITO) Thin Film Using CVD Technique. DOI: 10.24191/srj.v22i2.23000

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What industries commonly use PVD and CVD? Discover Key Applications in Tech and Manufacturing

- Why is diluted H2S gas preferred over solid sulfur for MoS2/WS2 synthesis? Precision CVD Control and Uniformity

- What role does a Chemical Vapor Deposition (CVD) system play in CsPbBr3 film growth? Master Single-Crystal Precision.

- What is the difference between CVD and Physical Vapor Deposition (PVD)? Choose the Right Coating Process

- Why must the deposition of an additional a-Si protective layer over a barrier layer be completed without breaking vacuum?

- Why is vacuum evaporation equipment necessary for g-C3N4 electronic devices? Achieving Atomic Interface Precision

- What roles do quartz boats and quartz tubes play in MoS2 CVD synthesis? Optimize Isotope-Engineered Monolayer Growth

- What is Chemical Vapor Deposition (CVD) used for? Unlock High-Performance Thin Films for Your Applications