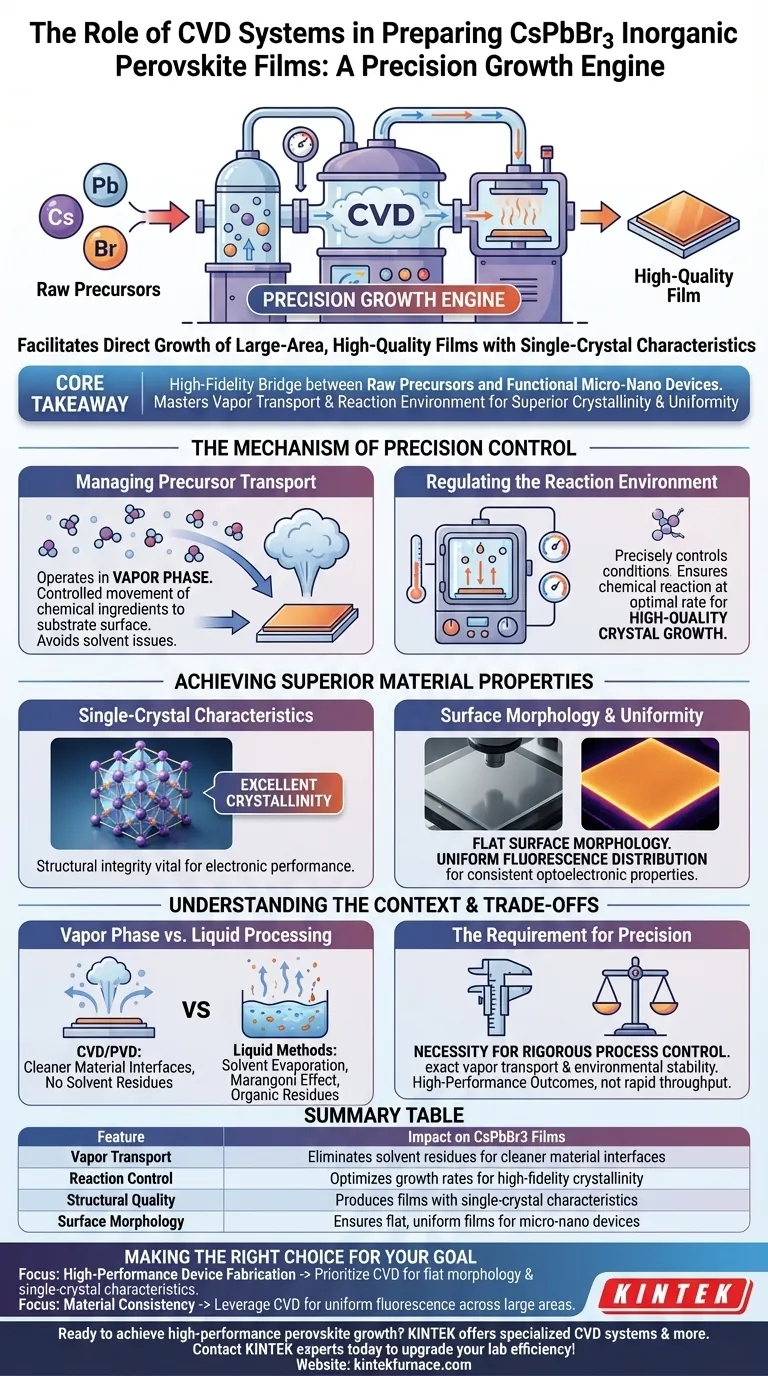

A Chemical Vapor Deposition (CVD) system serves as a precision growth engine for preparing CsPbBr3 inorganic perovskite films. It facilitates the direct growth of large-area, high-quality films that exhibit single-crystal characteristics on a target substrate.

Core Takeaway The CVD system functions as a high-fidelity bridge between raw precursors and functional micro-nano devices. By mastering the vapor transport and reaction environment, it produces CsPbBr3 films with superior crystallinity and surface uniformity that are difficult to achieve through standard solution-based methods.

The Mechanism of Precision Control

Managing Precursor Transport

The fundamental role of the CVD system is to manage the transport of precursor vapors.

Unlike liquid methods where precursors are dissolved in solvents, CVD operates in the vapor phase. This allows for the controlled movement of chemical ingredients to the substrate surface.

Regulating the Reaction Environment

Success in growing inorganic perovskites relies on a stable reaction environment.

The CVD system allows you to precisely control the conditions under which the CsPbBr3 forms. This regulation ensures the chemical reaction occurs at the optimal rate for high-quality crystal growth.

Achieving Superior Material Properties

Single-Crystal Characteristics

The most significant output of a properly tuned CVD process is the structural quality of the film.

The system enables the growth of films with excellent crystallinity, often possessing characteristics similar to single crystals. This structural integrity is vital for the electronic performance of the final material.

Surface Morphology and Uniformity

For micro-nano devices, the physical landscape of the film is as important as its internal structure.

CVD systems produce films with a flat surface morphology. Furthermore, they ensure a uniform fluorescence distribution, indicating that the optoelectronic properties are consistent across the entire large-area film.

Understanding the Context and Trade-offs

Vapor Phase vs. Liquid Processing

While liquid-based methods (like inkjet printing) focus on managing solvent evaporation and preventing effects like the Marangoni effect, vapor deposition takes a different approach.

CVD, similar to Physical Vapor Deposition (PVD), operates in a regime that avoids organic solvent residues. This eliminates "solvent-induced etching" problems often found in liquid processing, resulting in cleaner material interfaces.

The Requirement for Precision

The primary trade-off of using a CVD system is the necessity for rigorous process control.

Because the system relies on the exact transport of vapors and environmental stability, deviation in these parameters can disrupt the growth of single-crystal characteristics. It is a method designed for high-performance outcomes rather than rapid, low-fidelity throughput.

Making the Right Choice for Your Goal

If your primary focus is High-Performance Device Fabrication: Prioritize CVD to obtain the flat morphology and single-crystal characteristics required for efficient micro-nano devices.

If your primary focus is Material Consistency: Leverage the CVD system's ability to create uniform fluorescence distribution across large areas, ensuring reliable performance data.

The CVD system transforms volatile precursors into a robust, high-quality material platform essential for advanced inorganic perovskite applications.

Summary Table:

| Feature | Impact on CsPbBr3 Films |

|---|---|

| Vapor Transport | Eliminates solvent residues for cleaner material interfaces |

| Reaction Control | Optimizes growth rates for high-fidelity crystallinity |

| Structural Quality | Produces films with single-crystal characteristics |

| Surface Morphology | Ensures flat, uniform films for micro-nano devices |

Ready to achieve high-performance perovskite growth?

Backed by expert R&D and manufacturing, KINTEK offers specialized CVD systems, Tube, Rotary, Vacuum, and Muffle furnaces, all customizable for your unique lab requirements. Our technology empowers you to master vapor transport and reaction environments to produce superior CsPbBr3 films with unmatched consistency.

Contact KINTEK experts today to upgrade your lab efficiency!

Visual Guide

References

- Qi Han, Ji Li. Inorganic perovskite-based active multifunctional integrated photonic devices. DOI: 10.1038/s41467-024-45565-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why use high-precision temperature control in CVD for ITO thin films? Master Atom-Level Engineering Accuracy

- How does the material state differ between CVD and PVD processes? Uncover Key Differences for Better Coatings

- How do the process environments of PVD and CVD differ? Key Differences in Vacuum and Chemical Reactions

- What are the different types of CVD processes? Explore Key Variants for Thin Film Deposition

- What are the main applications of CVD? Discover High-Performance Coating Solutions

- What protective functions does a circulating water cooling system provide during CVD? Secure Vacuum Integrity Today

- How do IoT gas sensors and Autoencoders contribute to CVD furnace safety? Enhance Pipeline Integrity and Monitoring

- What is the typical deposition rate of CVD furnaces? Optimize Your Film Growth for Superior Results