In short, Chemical Vapor Deposition (CVD) is a cornerstone technology used across high-tech industries to create exceptionally thin, high-performance coatings. Its primary applications are in manufacturing semiconductors and integrated circuits, applying protective wear-resistant coatings for aerospace and automotive parts, and creating biocompatible surfaces for medical implants.

The true value of CVD is not in any single application, but in its fundamental ability to build materials atom by atom. This allows for the creation of ultra-pure, perfectly uniform films that give ordinary surfaces extraordinary properties.

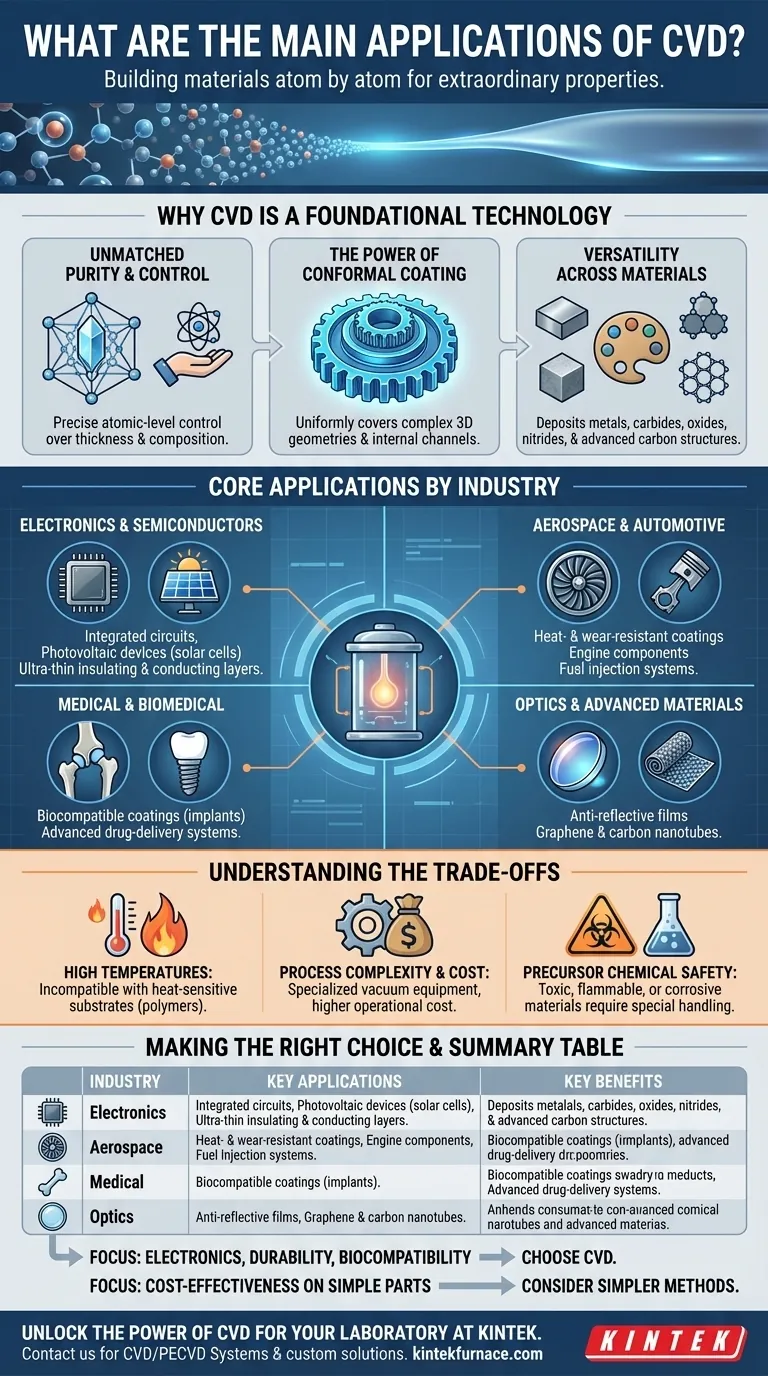

Why CVD is a Foundational Technology

Before looking at specific products, it’s critical to understand what makes the CVD process so uniquely powerful. Its advantages are the reason it has been adopted in so many demanding fields.

Unmatched Purity and Control

CVD allows for the deposition of films with extremely high purity. The process gives engineers precise, atomic-level control over the thickness and chemical composition of the coating, ensuring consistent performance.

The Power of Conformal Coating

A key advantage of CVD is its ability to create conformal coatings. This means the film perfectly and uniformly covers every surface of an object, including complex, three-dimensional geometries and internal channels that are impossible to coat with traditional line-of-sight methods.

Versatility Across Materials

The CVD process is not limited to a single type of material. It is highly versatile and can be used to deposit a wide range of substances, including metals, hard carbides, stable oxides, nitrides, and advanced carbon structures like graphene.

Core Applications by Industry

This unique combination of control, conformity, and versatility allows CVD to solve critical challenges across several key industries.

Electronics and Semiconductors

This is arguably the most significant application of CVD. The entire digital world is built on silicon chips, which rely on CVD to deposit the ultra-thin insulating, conducting, and semiconducting layers that form integrated circuits. It's also used to create the efficient layers in photovoltaic devices (solar cells).

Aerospace and Automotive

In environments defined by high heat and extreme friction, CVD provides critical protection. It's used to apply heat- and wear-resistant coatings on jet engine turbine blades and durable, low-friction coatings on automotive engine components and fuel injection systems, improving longevity and fuel efficiency.

Medical and Biomedical

When a material must safely interact with the human body, CVD is essential. It's used to apply inert, biocompatible coatings on medical implants like artificial joints and dental implants to prevent rejection. The technology is also being explored for advanced drug-delivery systems.

Optics and Advanced Materials

CVD is used to apply specialized coatings on lenses and optical instruments, such as anti-reflective films. Beyond this, it is a primary method for producing cutting-edge materials like graphene and carbon nanotubes, which have unique thermal, mechanical, and electrical properties for next-generation applications.

Understanding the Trade-offs

While powerful, CVD is not a universal solution. Its precision comes with specific constraints that make it unsuitable for certain applications.

High Temperatures and Substrate Limits

Many CVD processes require very high temperatures, often several hundred degrees Celsius. This makes the process incompatible with heat-sensitive substrate materials, such as many polymers or plastics.

Process Complexity and Cost

CVD is a sophisticated, vacuum-based process that requires specialized equipment and careful control of precursor gases. This complexity makes it significantly more expensive than simpler coating methods like painting or electroplating, especially for large-scale production.

Precursor Chemical Safety

The "vapor" in Chemical Vapor Deposition comes from precursor chemicals, which can be toxic, flammable, or corrosive. These materials require specialized handling, storage, and safety protocols, adding to the operational overhead.

Making the Right Choice for Your Goal

Selecting CVD depends entirely on whether its unique capabilities justify its complexity and cost for your specific objective.

- If your primary focus is electronic performance and precision: CVD is the non-negotiable industry standard for creating the pure, uniform films required for semiconductors.

- If your primary focus is durability in harsh environments: CVD provides unmatched heat, corrosion, and wear resistance for critical aerospace and automotive components.

- If your primary focus is biocompatibility: CVD is the proven method for creating safe, inert surfaces on medical devices that will be placed inside the human body.

- If your primary focus is cost-effectiveness on simple parts: For non-critical applications that don't require atomic precision or conformal coating, simpler methods are often more practical.

Ultimately, CVD empowers engineers and scientists to design materials from the atom up, redefining performance across countless industries.

Summary Table:

| Industry | Key Applications | Key Benefits |

|---|---|---|

| Electronics & Semiconductors | Integrated circuits, solar cells | High purity, precise control, uniform films |

| Aerospace & Automotive | Turbine blades, engine components | Wear resistance, heat protection, longevity |

| Medical & Biomedical | Implants, drug-delivery systems | Biocompatibility, safety, inert surfaces |

| Optics & Advanced Materials | Anti-reflective films, graphene | Conformal coating, versatility, unique properties |

Unlock the Power of CVD for Your Laboratory

At KINTEK, we specialize in providing advanced high-temperature furnace solutions, including our CVD/PECVD Systems, to help you achieve precise, high-performance coatings. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs in semiconductors, aerospace, medical devices, and more.

Contact us today to discuss how our tailored solutions can enhance your research and production efficiency!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- Why is maintaining gas pipelines important in MPCVD equipment? Ensure Purity and Safety in Crystal Growth

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- What are some applications of MPCVD? Unlock High-Purity Diamond for Advanced Engineering