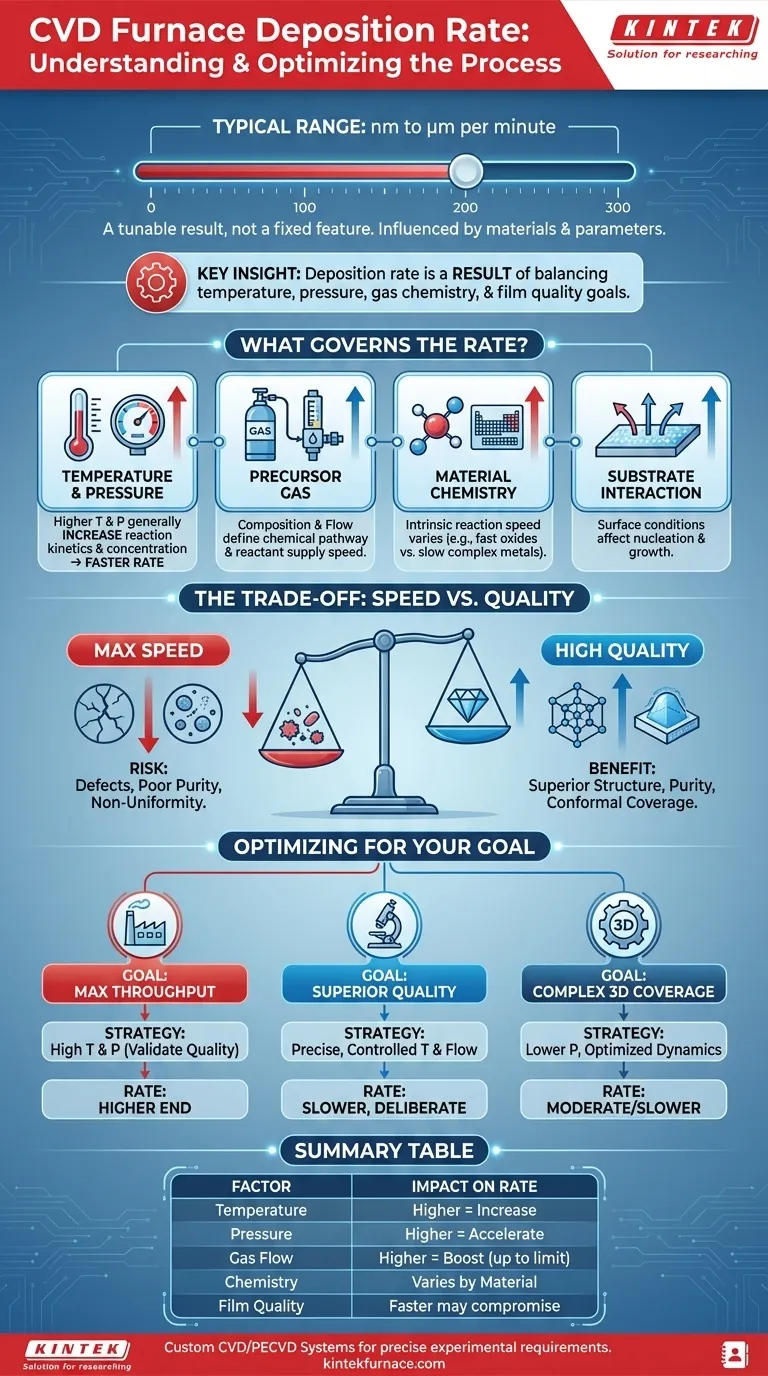

As a general benchmark, the deposition rate for a Chemical Vapor Deposition (CVD) furnace typically falls within a range of several nanometers to several micrometers per minute. This wide variation is not arbitrary; it is a direct consequence of the specific materials and process parameters being used. The rate is a highly tunable variable, not a fixed property of the furnace itself.

The crucial insight is that deposition rate is a result, not a feature. It is determined by a complex interplay between temperature, pressure, gas chemistry, and the desired film quality, which you must balance to achieve your specific engineering goal.

What Governs the Deposition Rate?

The final deposition rate is a function of several interdependent variables. Understanding these levers is essential for process control and optimization.

The Role of Temperature and Pressure

The CVD process is fundamentally driven by thermal energy. Higher temperatures generally increase the reaction kinetics, providing more energy for precursor molecules to decompose and form the film, leading to a faster deposition rate.

Similarly, higher pressure often increases the concentration of reactant species near the substrate surface, which can also accelerate the rate of deposition.

Precursor Gas Composition and Flow

The type of precursor gas and its concentration are primary factors. The chemical pathway of the deposition reaction dictates the intrinsic speed at which a film can form.

The flow rate of these gases into the chamber also plays a critical role. A higher flow rate can replenish reactants at the substrate surface more quickly, boosting the deposition rate up to a certain limit where the reaction becomes limited by temperature or surface chemistry.

The Chemistry of the Target Material

The material being deposited has a profound impact. Some materials, like certain oxides or nitrides, have chemical reactions that proceed very quickly under given conditions.

Others, particularly complex compounds or certain metals like tungsten, may have more intricate reaction mechanisms that naturally result in slower, more deliberate film growth.

Understanding the Trade-offs: Rate vs. Quality

Pursuing the maximum possible deposition rate almost always involves compromises. A faster process is not necessarily a better one.

The Risk of Poor Film Quality

Pushing for speed by dramatically increasing temperature or precursor concentration can lead to defects. This can manifest as poor crystal structure, increased impurities, or low film density.

For applications in semiconductors or optics, where material purity and structural perfection are paramount, a slower, more controlled deposition is often required to achieve the necessary quality.

Sacrificing Uniformity and Conformal Coverage

Extremely high deposition rates can lead to non-uniform film thickness across the substrate. This is especially true when coating complex, three-dimensional shapes.

Gas flow dynamics can create "shadowing" effects where some surfaces receive more precursor material than others. A slower, more deliberate process allows the gas to diffuse more evenly, resulting in a more conformal coating that uniformly covers all surfaces.

Optimizing Deposition Rate for Your Goal

The "correct" deposition rate is entirely dependent on your project's primary objective. Use the following guidelines to frame your approach.

- If your primary focus is maximum throughput and cost reduction: You will operate at the higher end of the temperature and pressure range for your material, but you must validate that the resulting film quality meets your minimum requirements.

- If your primary focus is superior film quality and uniformity: You will need to accept a slower deposition rate, using precisely controlled temperatures and gas flows to ensure a highly ordered and defect-free film structure.

- If your primary focus is coating complex 3D substrates: Your main challenge is conformal coverage, which often requires lower pressures and optimized gas dynamics, inherently favoring a more moderate or slower deposition rate.

Ultimately, treating the deposition rate as a tunable parameter, not a fixed limit, is the key to mastering the CVD process.

Summary Table:

| Factor | Impact on Deposition Rate |

|---|---|

| Temperature | Higher temperatures generally increase rate |

| Pressure | Higher pressure can accelerate rate |

| Gas Flow | Higher flow rates boost rate up to a limit |

| Material Chemistry | Intrinsic reaction speed varies by material |

| Film Quality | Faster rates may compromise quality and uniformity |

Ready to optimize your CVD processes with tailored furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including CVD/PECVD Systems, for diverse laboratories. Our strong deep customization capability ensures precise alignment with your unique experimental requirements, helping you achieve superior film quality, throughput, or conformal coverage. Contact us today to discuss how we can enhance your lab's performance!

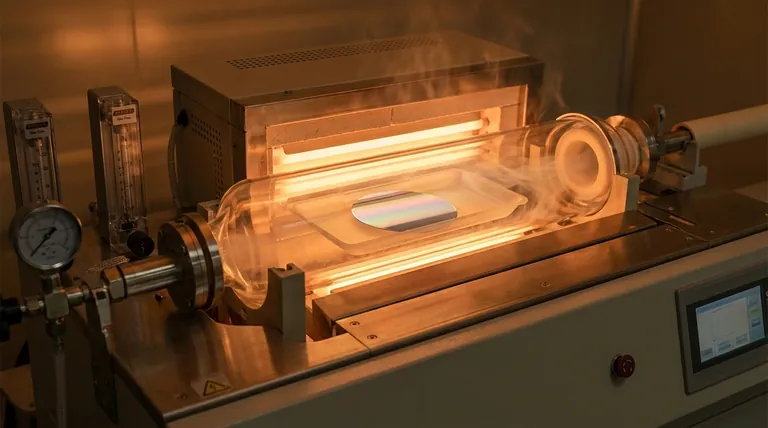

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab