A circulating water cooling system serves as the primary line of defense against thermal degradation in large-scale CVD operations. Its explicit function is to actively regulate the temperature of vacuum tube furnace flange seals, vacuum gaskets, and sensitive power supply components. By absorbing and dissipating the intense heat generated during synthesis, it prevents the physical breakdown of sealing materials and ensures the structural integrity of electrical systems.

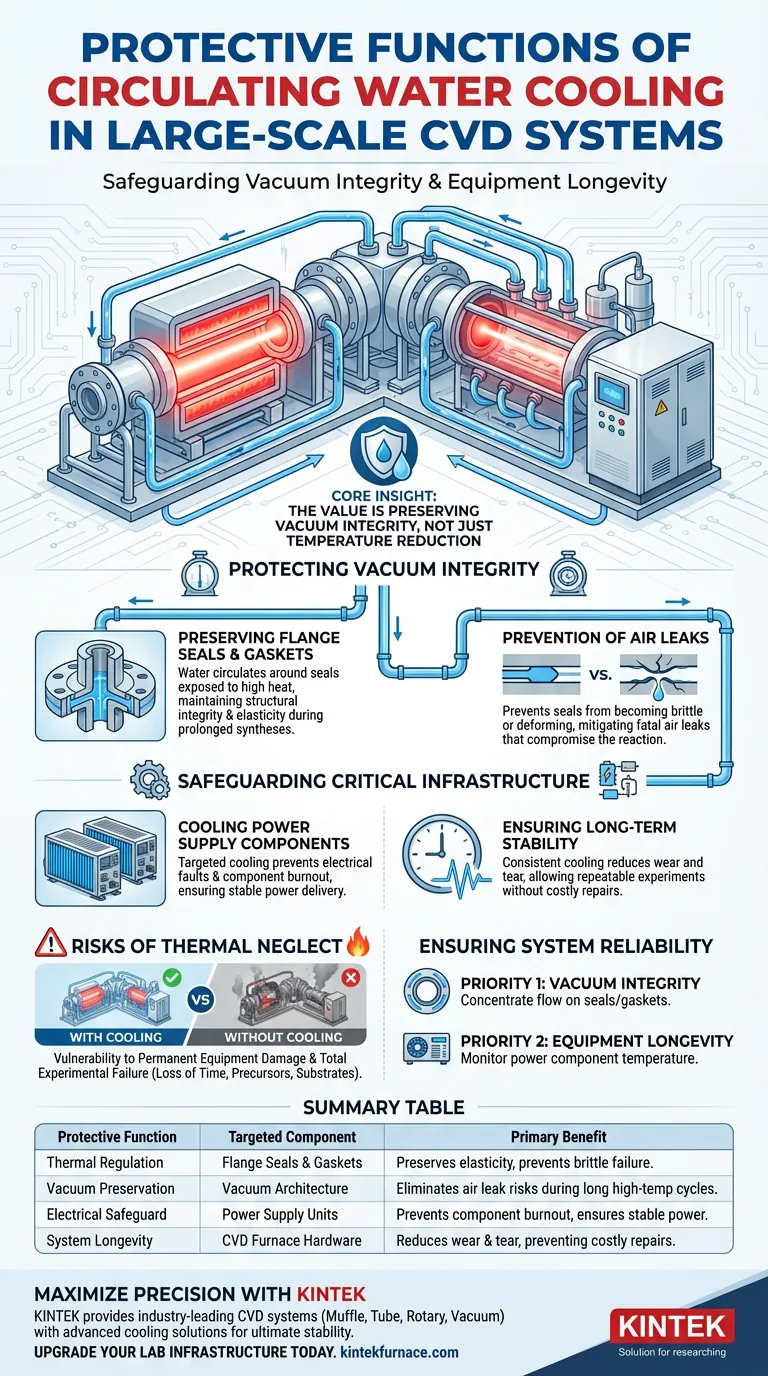

Core Insight: The value of a cooling system is not merely temperature reduction; it is the preservation of vacuum integrity. By protecting seals from overheating, the system prevents air leaks that would otherwise compromise the reaction environment, ensuring both experimental success and the long-term longevity of the equipment.

Protecting Vacuum Integrity

High-quality Chemical Vapor Deposition (CVD) relies on maintaining a pristine vacuum environment. The circulating water system is essential for sustaining this condition under thermal stress.

Preserving Flange Seals and Gaskets

CVD synthesis processes typically involve maintaining high temperatures for several hours.

During these prolonged cycles, static components like flange seals and vacuum gaskets are exposed to significant thermal radiation.

The water cooling system circulates fluid around these specific points to maintain their structural integrity and elasticity.

The Prevention of Air Leaks

If sealing materials overheat, they become brittle or deform, leading to immediate failure.

This failure creates a pathway for external air to penetrate the chamber.

By keeping these seals cool, the system effectively mitigates the risk of air leaks, which are fatal to the chemical deposition process.

Safeguarding Critical Infrastructure

Beyond the vacuum chamber, the cooling system protects the expensive hardware required to run the operation.

Cooling Power Supply Components

The system provides targeted cooling to critical power supply components.

These components generate their own internal heat during operation and are often located near the high-temperature furnace zones.

Active cooling prevents electrical faults and component burnout, ensuring the power delivery remains stable throughout the synthesis.

Ensuring Long-Term Stability

Consistent cooling is the key to the long-term stable operation of the entire CVD system.

Without this thermal management, the wear and tear on the system would accelerate drastically.

This protective function allows for repeatable experiments without the need for frequent, costly repairs.

Understanding the Risks of Thermal Neglect

While the cooling system adds complexity to the setup, the trade-off of operating without it is unacceptable risk.

Vulnerability to Equipment Damage

The primary reference highlights that cooling mitigates the risk of equipment damage.

Neglecting the cooling loop does not just ruin an experiment; it can permanently damage the furnace hardware and vacuum architecture.

The Cost of Experimental Failure

A single failure in a seal or power component leads to total experimental failure.

This results in the loss of valuable time, precursors, and substrates.

The cooling system functions as an insurance policy against these operational losses.

Ensuring System Reliability

To maximize the lifespan and efficiency of your CVD system, consider the following priorities:

- If your primary focus is Vacuum Integrity: Ensure the cooling flow is concentrated on flange seals and gaskets to prevent air leaks during long syntheses.

- If your primary focus is Equipment Longevity: Monitor the temperature of power supply components to prevent electrical burnout and reduce maintenance costs.

The circulating water cooling system is the foundational component that transforms a high-temperature furnace into a stable, reliable tool for precision material synthesis.

Summary Table:

| Protective Function | Targeted Component | Primary Benefit |

|---|---|---|

| Thermal Regulation | Flange Seals & Gaskets | Preserves seal elasticity and prevents brittle failure |

| Vacuum Preservation | Vacuum Architecture | Eliminates air leak risks during long high-temp cycles |

| Electrical Safeguard | Power Supply Units | Prevents component burnout and ensures stable power delivery |

| System Longevity | CVD Furnace Hardware | Reduces wear and tear, preventing costly mechanical repairs |

Maximize Your Lab’s Precision with KINTEK

Don't let thermal degradation compromise your synthesis results. KINTEK provides industry-leading CVD systems designed for ultimate stability and longevity. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which can be customized with advanced cooling solutions to meet your unique research needs.

Ready to upgrade your laboratory infrastructure? Contact our experts today to discover how our high-temperature furnace solutions can ensure the long-term success of your materials research.

Visual Guide

References

- Mitigating Silicon Amorphization in Si–Gr Anodes: A Pathway to Stable, High‐Energy Density Anodes for Li‐Ion Batteries. DOI: 10.1002/smll.202504704

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the process advantages of using an evaporation system with a rotating stage for TMO films? Achieve Uniformity

- What is a CVD furnace and what is its primary function? Discover Precision Thin-Film Deposition

- What role does a thermal evaporation coating system play in GeCC synthesis? Precision Seeding for Nanowire Growth

- How does a Molecular Turbo Pump contribute to ZTO thin film quality? Master High-Vacuum Deposition Precision

- What is the application of CVD in cutting tools? Boost Tool Life and Machining Efficiency

- How does CVD compare to other thin film deposition methods? Discover the Best Fit for Your Lab

- What role does a quartz tube reaction chamber play in CVD synthesis? Ensuring Purity in 2D TMD Growth

- How does a recirculating chiller influence the quality of polymer films in iCVD? Achieve Superior Surface Smoothness