The quartz tube acts as the critical high-temperature reaction center in Chemical Vapor Deposition (CVD) systems, specifically chosen to withstand the rigorous conditions required for synthesizing 2D Transition Metal Dichalcogenides (TMDs). It provides a physically stable vessel that resists temperatures up to 800 °C without deformation while remaining chemically inert against corrosive gases like H2S (hydrogen sulfide), ensuring the synthesized materials remain free of impurity ions.

Core Takeaway The quartz tube is not merely a container; it is an active isolation barrier that ensures semiconductor-grade purity. Its primary function is to resist the corrosive sulfurization process and extreme thermal stress, preventing the leaching of impurities that would otherwise degrade the electrical performance of sensitive 2D materials.

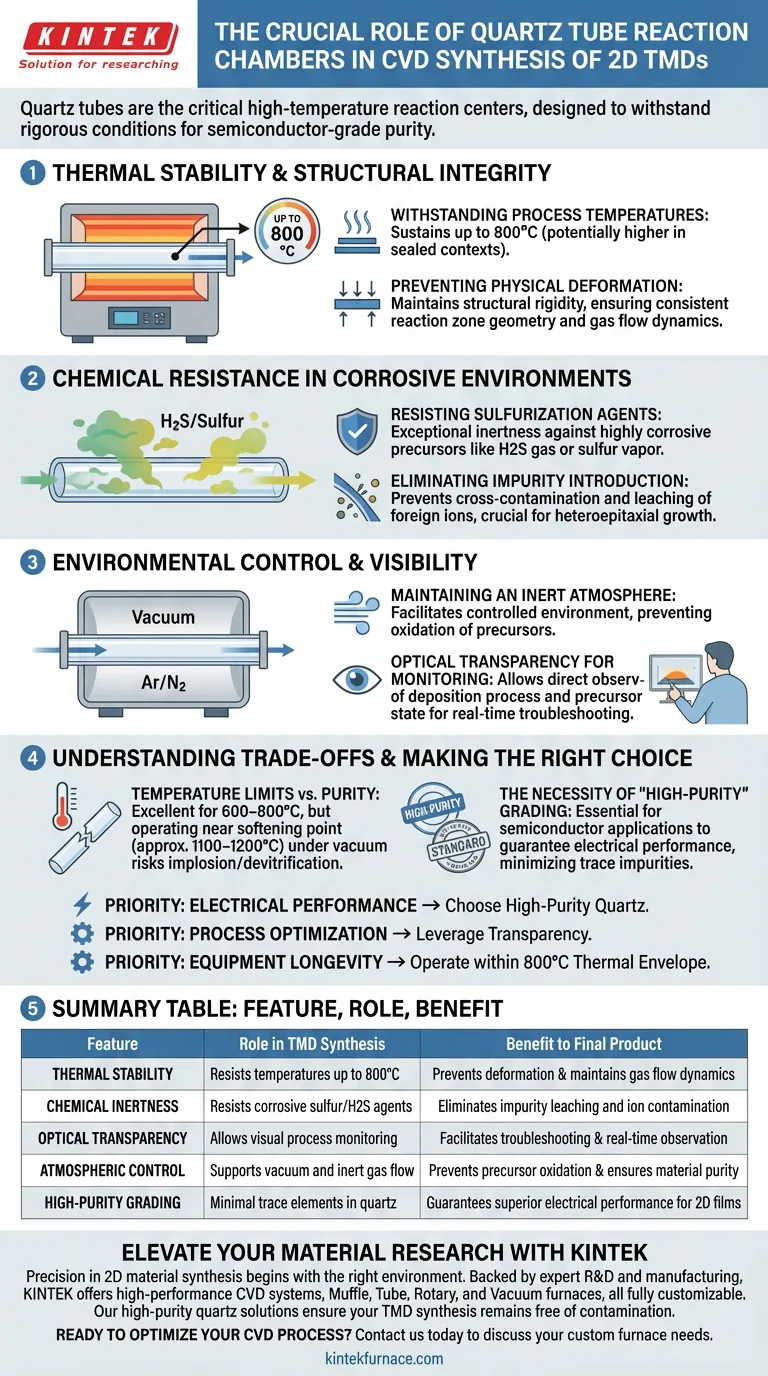

Thermal Stability and Structural Integrity

Withstanding Process Temperatures

Synthesis of TMDs requires elevated temperatures to facilitate the chemical reaction. An industrial-grade quartz tube acts as a robust chamber capable of sustaining temperatures up to 800 °C (and potentially higher in specific sealed contexts).

Preventing Physical Deformation

At these high processing temperatures, many materials soften or warp. Quartz maintains its structural rigidity, ensuring the geometry of the reaction zone remains constant. This stability is vital for maintaining consistent gas flow dynamics across the substrate.

Chemical Resistance in Corrosive Environments

Resisting Sulfurization Agents

TMD synthesis often involves highly corrosive precursors, such as H2S gas or sulfur vapor. The quartz tube exhibits exceptional chemical inertness, resisting corrosion that would rapidly degrade metal or lower-grade ceramic chambers.

Eliminating Impurity Introduction

The most critical role of the quartz tube is preventing cross-contamination. By resisting chemical erosion, the tube ensures that no foreign ions from the chamber walls leach into the reaction environment. This is essential for the heteroepitaxial growth of materials like MoS2, where even trace impurities can ruin electrical interfaces.

Environmental Control and Visibility

Maintaining an Inert Atmosphere

The tube facilitates a controlled environment, often under vacuum or inert gas flow. It prevents the oxidation of precursors and ensures that the raw materials (such as metal and sulfur powders) react only with each other, rather than with atmospheric oxygen.

Optical Transparency for Monitoring

Unlike opaque ceramic tubes, quartz offers optical transparency. This allows operators to directly observe the deposition process and the state of the precursors. This visibility is crucial for troubleshooting and ensuring the "clean" environment required to prevent thin film contamination is maintained.

Understanding the Trade-offs

Temperature Limits vs. Purity

While quartz is excellent for TMD synthesis (typically 600–800 °C), it has an upper thermal limit compared to alumina ceramics. Operating quartz too close to its softening point (approx. 1100–1200 °C) under vacuum can lead to implosion or devitrification (crystallization), which ruins the tube.

The Necessity of "High-Purity" Grading

Not all quartz is created equal. Standard fused silica may contain trace impurities that diffuse at high temperatures. For semiconductor applications, you must utilize high-purity industrial-grade quartz to guarantee the electrical performance of the final 2D material.

Making the Right Choice for Your Goal

When selecting a reaction chamber for TMD synthesis, align your choice with your specific research or production metric:

- If your primary focus is electrical performance: Prioritize high-purity quartz grades to eliminate ion leaching and ensure a pristine semiconductor interface.

- If your primary focus is process optimization: Leverage the transparency of the quartz to visually monitor precursor volatilization and flow dynamics in real-time.

- If your primary focus is equipment longevity: Ensure you operate strictly within the 800 °C thermal envelope referenced to prevent deformation over repeated heating cycles.

The success of CVD synthesis relies on the quartz tube serving as an invisible shield—chemically inert, thermally stable, and transparent.

Summary Table:

| Feature | Role in TMD Synthesis | Benefit to Final Product |

|---|---|---|

| Thermal Stability | Resists temperatures up to 800°C | Prevents deformation & maintains gas flow dynamics |

| Chemical Inertness | Resists corrosive sulfur/H2S agents | Eliminates impurity leaching and ion contamination |

| Optical Transparency | Allows visual process monitoring | Facilitates troubleshooting & real-time observation |

| Atmospheric Control | Supports vacuum and inert gas flow | Prevents precursor oxidation & ensures material purity |

| High-Purity Grading | Minimal trace elements in quartz | Guarantees superior electrical performance for 2D films |

Elevate Your Material Research with KINTEK

Precision in 2D material synthesis begins with the right environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance CVD systems, Muffle, Tube, Rotary, and Vacuum furnaces, all fully customizable to meet your unique laboratory requirements. Our high-purity quartz solutions ensure your TMD synthesis remains free of contamination while providing the thermal stability needed for consistent results.

Ready to optimize your CVD process? Contact us today to discuss your custom furnace needs and see how our expertise can drive your innovation forward.

Visual Guide

References

- Jungtae Nam, Keun‐Soo Kim. Tailored Synthesis of Heterogenous 2D TMDs and Their Spectroscopic Characterization. DOI: 10.3390/nano14030248

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the role of a horizontal oxidation furnace? Enhancing Silicon Micro-Tip Diffusion Barriers

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- How is the CVD process environment created? Master Precise Control for Superior Thin Films

- Why are graphene nanoribbons considered potential candidates for digital devices? Unlock Next-Gen Electronics

- What role does ultra-high vacuum PVD play in Pulsed Irradiation Synthesis? Build Pure Precursors for Metal Chalcogenides

- What types of materials can be synthesized using CVD? Unlock High-Purity Films for Electronics and More

- What are the key advantages of CVD coatings? Achieve Superior Durability and Uniformity for Complex Parts

- What is the function of a radio frequency (RF) plasma sputtering system? Precision PtNP Underlayer Fabrication