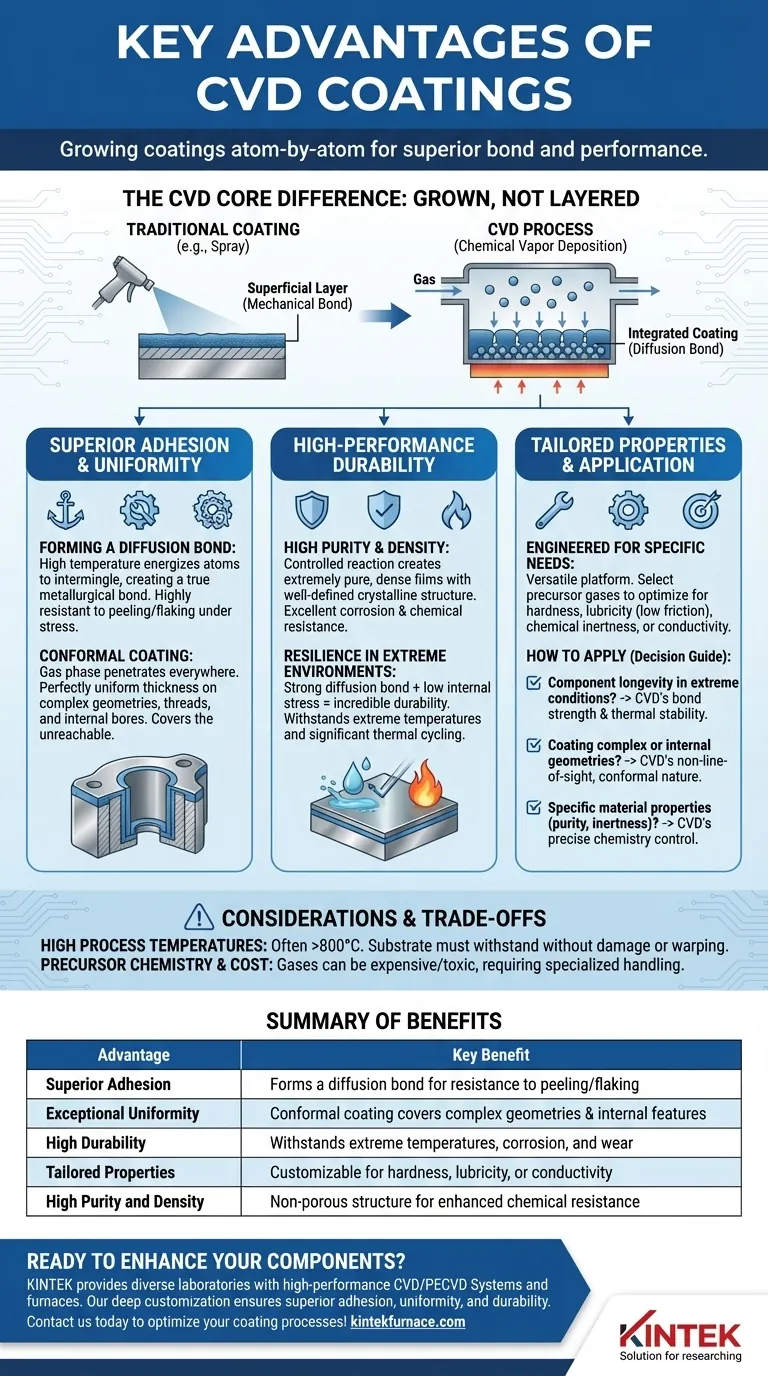

At its core, Chemical Vapor Deposition (CVD) creates coatings with superior adhesion, exceptional uniformity on complex shapes, and high-performance durability. Unlike methods that simply layer material onto a surface, CVD uses a chemical reaction to "grow" the coating directly on the substrate, integrating it at an atomic level. This fundamental difference is the source of its key advantages.

While many coating technologies cover a surface, few truly become a part of it. The primary advantage of CVD is its ability to form a dense, uniform, and exceptionally bonded film from a gas phase, making the coating an integral part of the component itself rather than just a superficial layer.

The Foundation: Why CVD Excels in Adhesion and Uniformity

The unique advantages of CVD stem directly from its fundamental process: building a solid film atom-by-atom from chemical precursors in a gas state.

From Gas to Solid: The Principle of Reaction

The CVD process involves introducing precursor gases into a reaction chamber containing the part to be coated. When these gases are heated, they decompose and react on the hot surface of the part, depositing a thin, solid film.

This process is not mechanical or line-of-sight; it is a chemical reaction occurring wherever the gas can reach the energized surface.

Creating a Diffusion Bond: Beyond Simple Adhesion

The high temperatures involved in many CVD processes energize the atoms of both the substrate and the depositing material. This energy allows them to intermingle at the interface, forming a diffusion bond.

This is not simple stickiness. It is a true metallurgical or chemical bond, resulting in exceptional adhesion that makes the coating highly resistant to peeling or flaking, even under significant stress.

Conformal Coating: Covering the Unreachable

Because the coating is formed from a gas, it can penetrate and coat any surface it can reach. This is known as a conformal coating.

This allows CVD to provide a perfectly uniform film thickness on highly complex geometries, including threads, sharp corners, and even certain internal bores and channels where line-of-sight methods like spraying or PVD would fail.

Unlocking Superior Performance Characteristics

The quality of the film created by CVD translates directly into tangible performance benefits for the coated component.

High Purity and Density for Durability

The controlled chemical reaction allows for the creation of films that are extremely pure and dense, with a well-defined crystalline structure.

This dense, non-porous structure is key to providing excellent resistance to corrosion and chemical attack, as there are no pathways for corrosive agents to reach the substrate. It also contributes to superior wear resistance.

Resilience in Extreme Environments

The combination of a strong diffusion bond and a pure, dense film with low internal stress gives CVD coatings incredible durability.

They can withstand extreme temperatures and significant thermal cycling without delaminating. This makes them ideal for components used in aerospace, automotive engines, and industrial processing where temperature fluctuation is common.

Tailored Properties for Specific Applications

CVD is not a single coating but a versatile platform. By carefully selecting the precursor gases, the properties of the final film can be precisely engineered.

This allows for the creation of coatings optimized for specific needs, such as high hardness, lubricity (low friction), chemical inertness, or electrical conductivity.

Understanding the Trade-offs and Considerations

No technology is a universal solution. To make an informed decision, it's critical to understand the operational context of CVD.

The Impact of High Process Temperatures

Traditional CVD processes often require high temperatures (often >800°C) to drive the necessary chemical reactions. This can be a significant limitation.

Substrate materials must be able to withstand these temperatures without being damaged or undergoing undesirable changes, such as the softening or warping of certain heat-treated steels. This factor must be a primary consideration during material selection.

Precursor Chemistry and Cost

The gases used in CVD can be expensive, toxic, or corrosive, requiring specialized handling equipment and safety protocols. These factors contribute to the overall cost and complexity of the operation.

While the performance benefits often justify the investment, CVD may not be the most cost-effective solution for simple applications where a less durable coating is sufficient.

How to Apply This to Your Engineering Goal

Your choice to use CVD should be driven by the specific problem you are trying to solve.

- If your primary focus is component longevity in extreme conditions: CVD's exceptional bond strength and thermal stability are your greatest assets for preventing wear, corrosion, and heat-related failure.

- If your primary focus is coating complex or internal geometries: CVD's non-line-of-sight, gas-phase nature is often the only technically viable solution for ensuring complete and uniform coverage.

- If your primary focus is achieving specific material properties (e.g., high purity, inertness): The precise control over precursor chemistry makes CVD a superior choice for custom-engineering surface performance.

- If your primary focus is coating a temperature-sensitive material on a tight budget: You must carefully evaluate if a lower-temperature CVD variant is suitable or if a different coating technology is a more practical fit.

By understanding its foundational principles, you can leverage CVD not just as a coating, but as a fundamental design tool to solve your most demanding engineering challenges.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Adhesion | Forms a diffusion bond for resistance to peeling and flaking |

| Exceptional Uniformity | Conformal coating covers complex geometries and internal features |

| High Durability | Withstands extreme temperatures, corrosion, and wear |

| Tailored Properties | Customizable for hardness, lubricity, or conductivity |

| High Purity and Density | Non-porous structure for enhanced chemical resistance |

Ready to enhance your components with advanced CVD coatings? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-performance solutions like our CVD/PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior adhesion, uniformity, and durability in extreme conditions. Contact us today to discuss how we can optimize your coating processes!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics