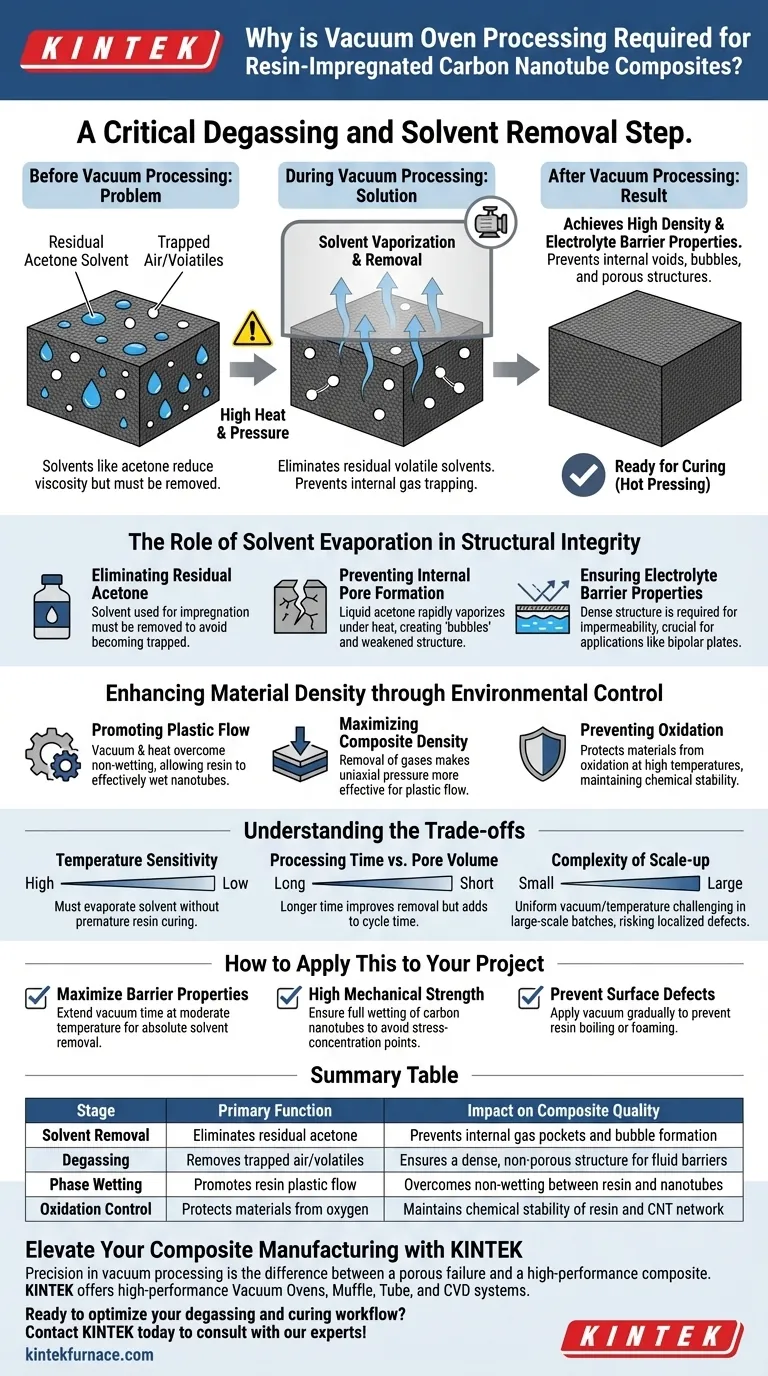

Vacuum oven processing is a critical degassing and solvent removal step. It serves as the primary safeguard against structural defects by removing residual solvents—specifically acetone—before the resin undergoes final curing. Without this phase, the subsequent application of heat and pressure would trigger solvent vaporization within the material, leading to the formation of internal voids and porous structures that compromise the composite's integrity.

Vacuum oven processing eliminates residual volatile solvents to prevent internal gas trapping and "bubble" formation. This step is essential for achieving the high density and electrolyte barrier properties required for functional horizontally aligned carbon nanotube (HACN) composites.

The Role of Solvent Evaporation in Structural Integrity

Eliminating Residual Acetone

Resin impregnation often utilizes acetone as a solvent to reduce viscosity and ensure the resin fully penetrates the carbon nanotube (CNT) network. If this solvent is not removed before the curing process begins, it becomes trapped within the matrix.

Preventing Internal Pore Formation

During the subsequent high-pressure hot pressing phase, any remaining liquid acetone will rapidly vaporize due to elevated temperatures. This creates internal gas pockets or "bubbles" that result in a porous, weakened final structure.

Ensuring Electrolyte Barrier Properties

For applications like bipolar plates (HACN-BP), the material must be completely impermeable to fluids. Vacuum processing ensures a dense structure, which is the only way to provide the effective barrier properties needed to prevent electrolyte leakage.

Enhancing Material Density through Environmental Control

Promoting Plastic Flow and Rearrangement

A vacuum environment, particularly when combined with heat, helps overcome the physical barriers of non-wetting between different material phases. By removing air and volatiles, the resin can more effectively wet the nanotubes.

Maximizing Composite Density

The removal of gases allows the application of uniaxial pressure to be more effective. Instead of compressing trapped air, the pressure works to promote the plastic flow of the materials, resulting in a significantly higher-density composite.

Preventing Oxidation

While primarily critical in metallic-reinforced composites, the vacuum environment also protects the materials from oxidation at high temperatures. This ensures that the chemical properties of both the resin and the carbon nanotubes remain stable throughout the thermal cycle.

Understanding the Trade-offs

Temperature Sensitivity

The vacuum oven temperature must be high enough to evaporate the solvent but low enough to avoid premature resin curing. If the resin begins to cross-link too early, it will trap the remaining solvent, defeating the purpose of the vacuum stage.

Processing Time vs. Pore Volume

Increasing the duration of the vacuum cycle improves the removal of volatiles, leading to a more reliable part. However, this adds significant cycle time to the manufacturing process, requiring a balance between production throughput and material quality.

Complexity of Scale-up

While effective for small-scale plates, maintaining a uniform vacuum and temperature profile across large-scale batches can be challenging. Inconsistent vacuum processing leads to localized defects, where some areas of a composite plate are dense while others remain porous.

How to Apply This to Your Project

When preparing resin-impregnated nanotubes for curing, your processing parameters should align with your final performance requirements.

- If your primary focus is maximizing barrier properties: Extend the vacuum processing time at a moderate temperature to ensure the absolute removal of all volatile solvents before applying pressure.

- If your primary focus is high mechanical strength: Use the vacuum stage to ensure the resin fully wets the carbon nanotubes, as any residual solvent will create stress-concentration points that lead to premature failure.

- If your primary focus is preventing surface defects: Ensure the vacuum is applied gradually to prevent the resin from "boiling" or foaming, which can displace the aligned nanotubes.

Proper vacuum processing transforms a potentially porous mixture into a high-performance, dense composite suitable for demanding electrochemical environments.

Summary Table:

| Stage | Primary Function | Impact on Composite Quality |

|---|---|---|

| Solvent Removal | Eliminates residual acetone | Prevents internal gas pockets and bubble formation |

| Degassing | Removes trapped air/volatiles | Ensures a dense, non-porous structure for fluid barriers |

| Phase Wetting | Promotes resin plastic flow | Overcomes non-wetting between resin and nanotubes |

| Oxidation Control | Protects materials from oxygen | Maintains chemical stability of resin and CNT network |

Elevate Your Composite Manufacturing with KINTEK

Precision in vacuum processing is the difference between a porous failure and a high-performance composite. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Ovens, Muffle, Tube, and CVD systems designed to provide the rigorous environmental control needed for carbon nanotube and advanced material research.

Whether you need customizable thermal profiles to prevent premature curing or superior vacuum integrity for degassing, our lab solutions are engineered for your unique needs.

Ready to optimize your degassing and curing workflow? Contact KINTEK today to consult with our experts!

Visual Guide

References

- Jae‐Moon Jeong, Seong Su Kim. Aligned Carbon Nanotube Polymer Nanocomposite Bipolar Plates Technology for Vanadium Redox Flow Batteries. DOI: 10.1002/eem2.70030

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of using a vacuum environment in heat treatment? Achieve Superior Metallurgical Control

- What are the main advantages of vacuum heat treatment? Achieve Superior Metallurgical Outcomes and Cost Efficiency

- Why is a vacuum environment important in a vacuum furnace? Ensure Purity and Precision in Material Processing

- Why is vacuum degassing equipment utilized in the preparation of low-alloy fire-resistant steel? | KINTEK Solutions

- Why is a laboratory vacuum oven with nitrogen protection used for alumina dehydration? Ensure High-Purity Surfaces

- Why is a vacuum preheating furnace used for aluminum foam sandwich panels? Ensure High-Strength Metallic Bonding

- What role does an industrial high-temperature vacuum furnace play in the post-treatment of semiconductor nanocrystals?

- What are the benefits of using vacuum and controlled environments in sintering furnaces? Achieve Superior Material Quality and Efficiency