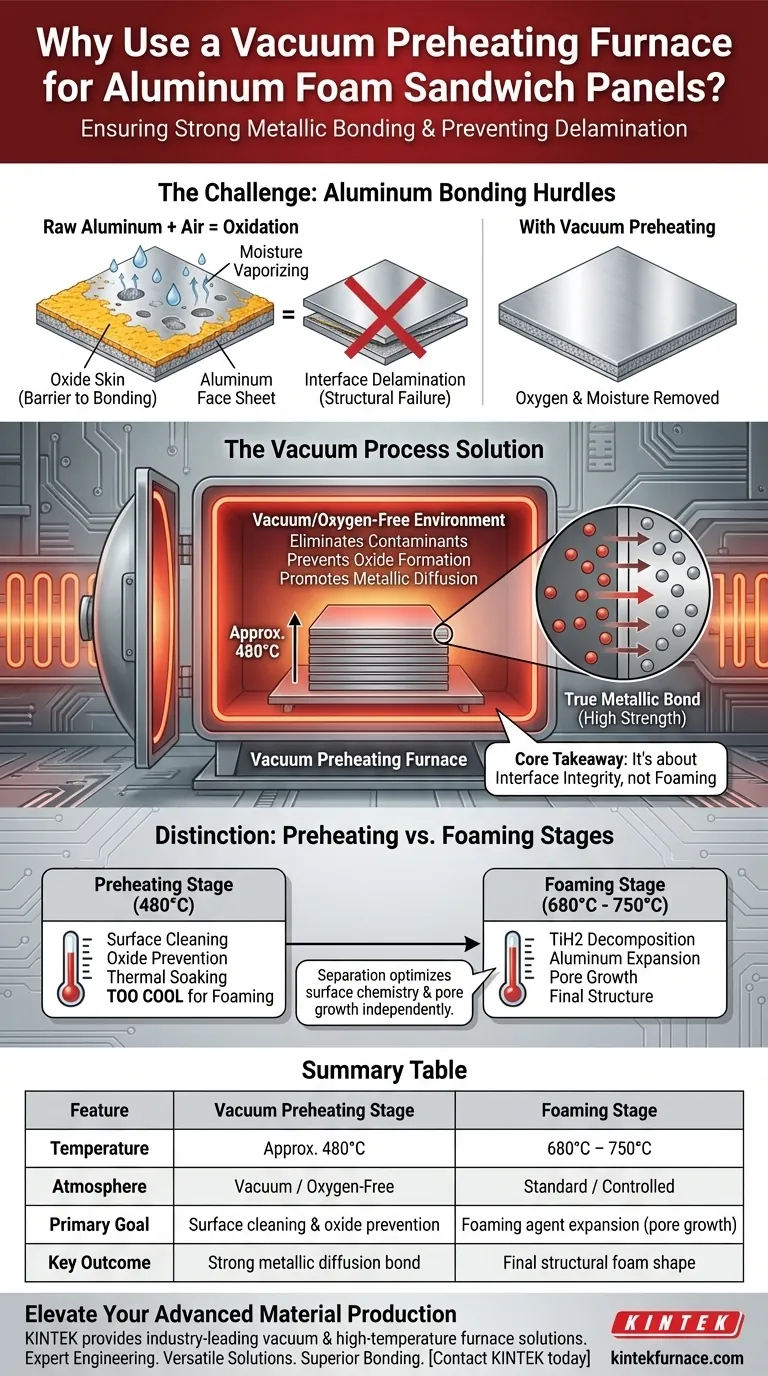

The primary function of a vacuum preheating furnace is to create a pristine, oxygen-free environment that prepares the sandwich panel blanks for bonding. By heating the materials to approximately 480°C, this process removes surface moisture and prevents the formation of oxide layers on the metal face sheets. This step is critical because it ensures the face sheets create a high-strength metallic bond with the foam core during the subsequent expansion phase, preventing structural failure.

Core Takeaway The vacuum preheating stage is not about expanding the foam, but about ensuring interface integrity. By eliminating oxygen and moisture, it prevents the face sheets from delaminating, ensuring the final sandwich panel functions as a single, cohesive structural unit.

The Challenge of Aluminum Bonding

The Oxidation Barrier

Aluminum creates a tough oxide skin almost instantly when exposed to air. While this protects raw aluminum, it acts as a barrier to bonding during the manufacturing of sandwich panels.

The Threat of Delamination

If this oxide layer is allowed to form or thicken during heating, the metal face sheets will not fuse with the molten foam core. This leads to interface delamination, where the face sheets peel away from the core, rendering the panel structurally useless.

Eliminating Contaminants

Surface moisture on the raw materials can vaporize and create voids or defects at the bond line. The vacuum furnace effectively removes this moisture before the critical bonding phase begins.

How the Vacuum Process Solves It

Creating an Oxygen-Free Zone

The furnace operates in a vacuum or low-oxygen environment. This allows the material to reach high temperatures (approx. 480°C) without reacting with the atmosphere.

Promoting Metallic Diffusion

Because the metal surfaces remain clean, atoms can diffuse between the face sheet and the core material. This results in a true metallic bond, which is significantly stronger than a mechanical or adhesive bond.

Thermal Stability

Heating the material to 480°C ensures the entire blank is thermally soaked and ready for the next stage. This uniform temperature profile prevents thermal shock when the panel enters the much hotter foaming furnace.

Distinction: Preheating vs. Foaming

The Preheating Stage (480°C)

It is crucial not to confuse preheating with the actual foaming process. The vacuum furnace holds the material at roughly 480°C, which is hot enough to condition the metal but too cool to trigger rapid foaming.

The Foaming Stage (680°C - 750°C)

After preheating, the panel is moved to a high-precision box furnace, as noted in supplementary technical data. Here, temperatures are raised to between 680°C and 750°C to decompose the foaming agent (TiH2) and expand the aluminum.

Why Separation Matters

Separating these stages allows you to optimize surface chemistry (in the vacuum furnace) independently of pore growth (in the high-temperature box furnace). Attempting to do both in a standard atmosphere would result in poor bonding and oxidized skins.

Understanding the Trade-offs

Process Complexity vs. Product Reliability

Implementing a vacuum stage adds capital cost and cycle time to the manufacturing process. However, skipping this step introduces a high risk of inconsistent bonding, making the final product unsuitable for load-bearing applications.

Temperature Limits

The preheating temperature must be strictly controlled around 480°C. If the vacuum furnace runs too hot, it may prematurely activate the foaming agent before the material is moved to the expansion chamber, ruining the pore structure.

Making the Right Choice for Your Goal

When designing your manufacturing workflow for aluminum foam sandwich panels, consider your performance requirements:

- If your primary focus is Structural Integrity: You must prioritize the vacuum preheating stage to prevent oxidation and ensure the face sheets cannot delaminate under load.

- If your primary focus is Pore Uniformity: Ensure your subsequent foaming furnace (not the preheater) has high-precision temperature control (680-750°C) to manage the expansion of the precursor.

Summary: The vacuum preheating furnace is the guardian of the bond line, ensuring that the high-performance foam core remains securely attached to its protective metal skin.

Summary Table:

| Feature | Vacuum Preheating Stage | Foaming Stage |

|---|---|---|

| Temperature | Approx. 480°C | 680°C – 750°C |

| Atmosphere | Vacuum / Oxygen-Free | Standard / Controlled |

| Primary Goal | Surface cleaning & oxide prevention | Foaming agent expansion (pore growth) |

| Key Outcome | Strong metallic diffusion bond | Final structural foam shape |

Elevate Your Advanced Material Production with KINTEK

Don't let oxidation compromise the structural integrity of your aluminum foam sandwich panels. KINTEK provides industry-leading vacuum and high-temperature furnace solutions designed for the most demanding R&D and manufacturing workflows.

Our Value to You:

- Expert Engineering: Backed by professional R&D, our systems ensure precise thermal profiles for both preheating and foaming stages.

- Versatile Solutions: Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our equipment is fully customizable to your unique material requirements.

- Superior Bonding: Our vacuum technology eliminates contaminants and oxide barriers, ensuring your panels achieve a true metallic bond without delamination.

Ready to optimize your lab's efficiency and product reliability? Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

References

- Xiaotong Lu, Xiaocheng Li. Pore Structure and Deformation Correlation of an Aluminum Foam Sandwich Subject to Three-Point Bending. DOI: 10.3390/ma17030567

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What processes are hot wall vacuum furnaces used for? Ideal for precise, uniform low-temperature heat treatments

- What processes can vacuum carburizing furnaces perform? Unlock Versatile Heat Treatment Solutions

- Why is an Ultra-High Vacuum (UHV) System Required for In2Se3? Achieving Atomic-Level Ferroelectric Clarity

- What temperature is vacuum brazing? Achieve Strong, Flux-Free Joints in a Controlled Environment

- What are the key properties of vacuum brazed connections? Achieve Strong, Clean, and Hermetic Joints

- What is the function of a molten salt electrochemical cell or furnace? Efficient Silicon Material Production Secrets

- What is the difference between a muffle furnace and a vacuum furnace? Choose the Right Heat for Your Process

- What are the main applications of vacuum furnaces? Achieve Superior Material Quality and Performance