The installation of an oxygen analyzer at the exhaust end is the definitive safety checkpoint for preventing catastrophic failure in a Roll-to-Roll (R2R) system. It serves as the primary verification tool to confirm that the reaction chamber is chemically inert before high-risk operations begin. Without this specific data point, introducing flammable precursor gases into a heated environment would rely on guesswork, creating an immediate and severe risk of explosion.

The analyzer acts as a critical "hard stop" in the safety protocol. By verifying that residual oxygen levels have dropped below 0.5% before allowing the introduction of explosive gases like acetylene, it provides the essential interlocking data necessary to prevent oxidation and ensure safe, continuous operation.

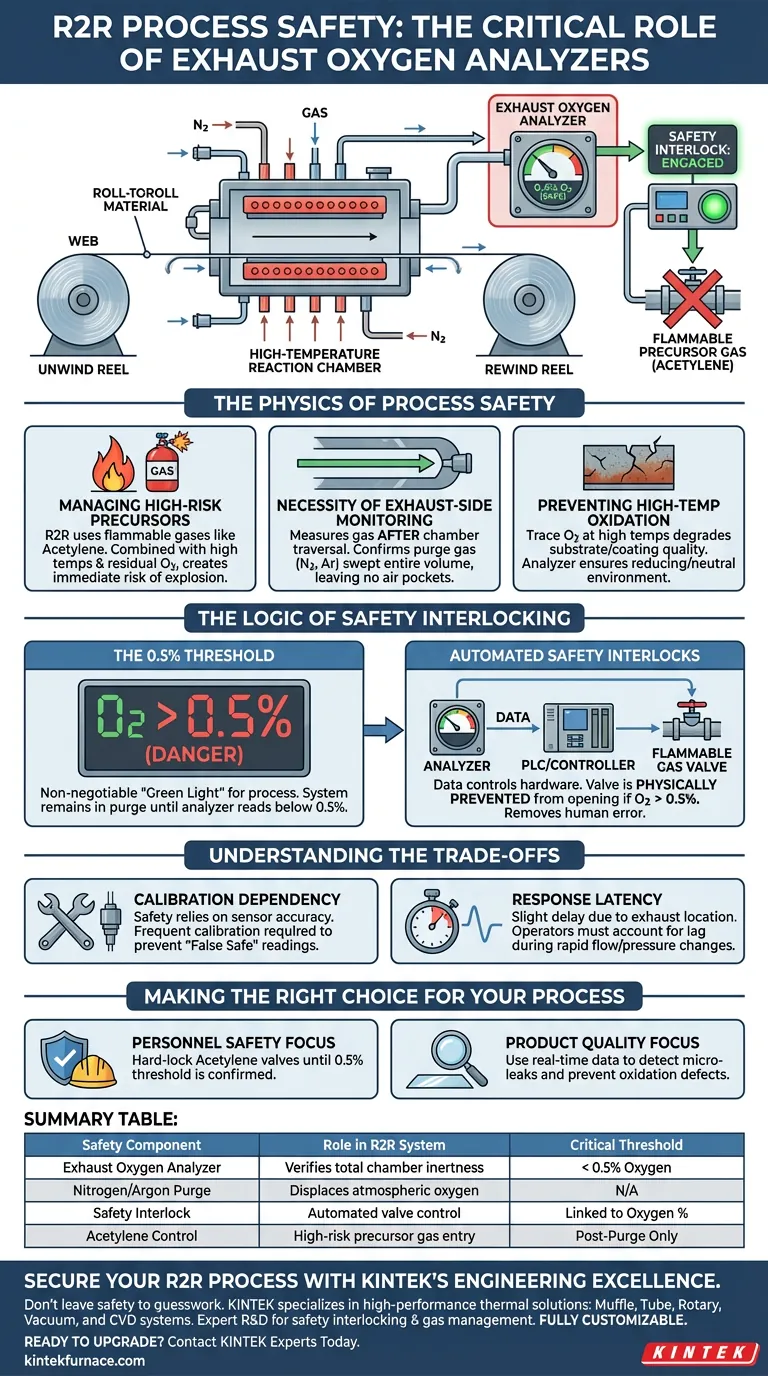

The Physics of Process Safety

Managing High-Risk Precursors

R2R systems frequently require the use of flammable and explosive gases, such as acetylene, to facilitate reactions.

These gases are highly unstable in the presence of oxidizers.

Because the system operates at elevated temperatures, the combination of acetylene and residual atmospheric oxygen creates a perfect environment for immediate combustion or explosion.

The Necessity of Exhaust-Side Monitoring

Placing the analyzer at the exhaust end is a strategic design choice, not arbitrary.

It measures the gas after it has traversed the entire reaction chamber.

This confirms that the purging gas (usually nitrogen or argon) has successfully swept the entire volume of the chamber, leaving no pockets of air behind.

Preventing High-Temperature Oxidation

Beyond the risk of explosion, oxygen causes rapid oxidation of the materials being processed.

At high temperatures, even trace amounts of oxygen can degrade the quality of the substrate or the coating.

The analyzer ensures the environment is chemically reducing or neutral, protecting the integrity of the product.

The Logic of Safety Interlocking

The 0.5% Threshold

The primary reference establishes a strict safety limit: the oxygen concentration must be below 0.5%.

This is the non-negotiable "Green Light" for the process.

Until the analyzer reads below this specific value, the system remains in a purging state.

Automated Safety Interlocks

The data provided by the analyzer does more than inform the operator; it controls the hardware.

This creates a safety interlock: the valves for flammable gases (acetylene) are physically prevented from opening if the oxygen level is above the threshold.

This mechanism removes the potential for human error, ensuring that dangerous gases cannot be introduced into an oxygen-rich environment.

Understanding the Trade-offs

Calibration Dependency

The safety of the entire system relies heavily on the accuracy of the sensor.

If the analyzer is not calibrated frequently, it may report a "false safe" (a low reading when oxygen is actually high).

Operators must treat sensor maintenance with the same priority as the operation of the furnace itself.

Response Latency

Because the analyzer is located at the exhaust, there is a slight delay between a change in the chamber and the reading on the sensor.

Operators must account for this lag time.

Rapid changes in flow or pressure might not be immediately reflected in the oxygen reading, requiring conservative operational changes.

Making the Right Choice for Your Process

To ensure the safety and longevity of your R2R system, your operational protocols must center around this critical data point.

- If your primary focus is Personnel Safety: Ensure your control software is programmed to hard-lock acetylene valves until the 0.5% threshold is confirmed by the analyzer.

- If your primary focus is Product Quality: Use the real-time data from the analyzer to detect micro-leaks in the vacuum or sealing system that could introduce oxidation defects.

True process safety is achieved when you treat the oxygen analyzer not as a monitor, but as the master key to your reaction chamber.

Summary Table:

| Safety Component | Role in R2R System | Critical Threshold |

|---|---|---|

| Exhaust Oxygen Analyzer | Verifies total chamber inertness before gas introduction | < 0.5% Oxygen |

| Nitrogen/Argon Purge | Displaces atmospheric oxygen and creates a neutral environment | N/A |

| Safety Interlock | Automated valve control preventing flammable gas entry | Linked to Oxygen % |

| Acetylene Control | High-risk precursor gas entry only after safety verification | Post-Purge Only |

Secure Your R2R Process with KINTEK’s Engineering Excellence

Don't leave your laboratory's safety to guesswork. At KINTEK, we specialize in high-performance thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Our expert R&D team understands the critical necessity of safety interlocking and precise gas management for Roll-to-Roll operations.

Whether you need a custom-built high-temperature furnace or expert guidance on integrating safety analyzers into your workflow, our systems are fully customizable to meet your unique research and manufacturing needs.

Ready to upgrade your lab’s safety and precision? Contact KINTEK Experts Today

Visual Guide

References

- Jean‐Luc Meunier, Jason R. Tavares. Continuous Reactive-Roll-to-Roll Growth of Carbon Nanotubes for Fog Water Harvesting Applications. DOI: 10.3390/c10010009

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What type of power supply is used in CVD furnaces? Discover Precision SCR Systems for Superior Thin Films

- What are the techniques for vapor deposition? PVD vs. CVD for Superior Thin-Film Coatings

- What is the function of the 800 °C argon heat treatment in CNT prep? Mastering Roll-to-Roll Substrate Engineering

- How does MOCVD work? A Guide to Atomic-Level Thin Film Deposition

- What are the advantages of using a CVD tube furnace for preparing gate media? Achieve Superior Film Control and Purity

- What are the key considerations for selecting a CVD furnace for laboratory use? Optimize Your Lab's CVD Setup

- How do quartz tube dimensions influence MoS2 CVD synthesis? Optimize Flow for High-Quality Monolayers

- What role does Chemical Vapor Deposition (CVD) equipment play in the processing of composite nanomaterials?