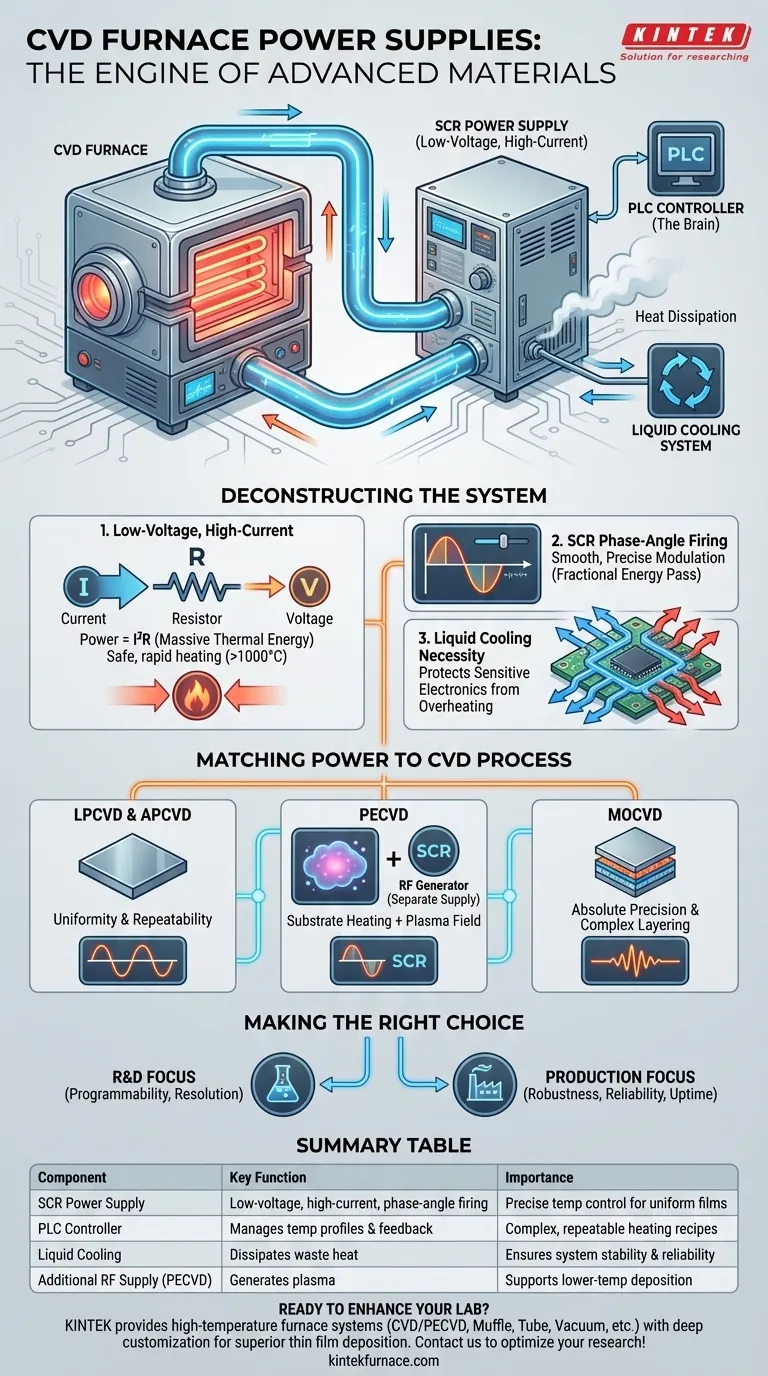

At its core, a Chemical Vapor Deposition (CVD) furnace uses a low-voltage, high-current Silicon-Controlled Rectifier (SCR) power supply. This system is specifically engineered for the extreme demands of the CVD process, where precise and stable temperature control is not just a feature, but the foundation of creating high-quality, uniform thin films and materials. The entire system is typically managed by a Programmable Logic Controller (PLC) and requires liquid cooling to handle the immense power involved.

The choice of a power supply in a CVD system is driven by one primary requirement: delivering vast amounts of thermal energy with exceptional precision. An SCR-based system is not merely providing electricity; it is the heart of the thermal control loop that dictates the success or failure of the deposition process.

Deconstructing the CVD Power Supply

To understand why this specific configuration is the industry standard, we must break down each component and its role in the complex thermal management of a CVD furnace.

Why Low Voltage and High Current?

The heating elements inside a CVD furnace are essentially large resistors. According to the principle of resistive heating (Power = Current² × Resistance), generating the high temperatures needed for deposition (often exceeding 1000°C) requires a massive amount of power.

Using a low-voltage, high-current approach is a practical and safe engineering solution. High current delivers the raw power needed for rapid heating, while keeping the voltage relatively low improves operational safety compared to a high-voltage equivalent.

The Role of the SCR (Silicon-Controlled Rectifier)

The SCR is the critical component for temperature regulation. Think of it as an incredibly fast and robust electronic switch or valve for electricity.

The power supply doesn't simply turn on and off. Instead, the SCRs use a technique called phase-angle firing to precisely "chop up" the AC power waveform, allowing only a specific fraction of the electrical energy to pass through to the heating elements. By adjusting this fraction thousands of times per second, the SCR provides exceptionally smooth and accurate power modulation.

The Necessity of Liquid Cooling

Managing high-current electricity is an inefficient process that generates significant waste heat within the power supply cabinet itself. The SCRs and other power electronics can be easily damaged or destroyed by overheating.

Liquid cooling (typically using deionized water) is not optional; it's a mandatory feature. It continuously circulates through the power supply, absorbing waste heat and transferring it away from the sensitive electronics, ensuring the system remains stable and reliable during long, high-temperature processing runs.

The Brains of the Operation: PLC Control

A Programmable Logic Controller (PLC) is a ruggedized industrial computer that serves as the master controller. It runs the heating "recipe" by executing a pre-programmed temperature profile.

The PLC constantly reads temperature data from thermocouples inside the furnace and, based on that feedback, commands the SCR driver board to adjust the power output. This closed-loop control allows for complex, multi-step processes with precise ramps and soaks, which are essential for advanced material synthesis.

Matching Power to the CVD Process

Different CVD techniques have unique requirements, but all rely on the foundational stability of the SCR power supply. The specific demands of the process highlight why this precision is so critical.

Uniformity in LPCVD and APCVD

In Low-Pressure (LPCVD) and Atmospheric Pressure (APCVD) systems, the reaction is primarily driven by thermal energy. Any fluctuation in temperature across the substrate results in non-uniform film thickness and inconsistent material properties. The stability of the SCR power supply is directly responsible for process repeatability and yield.

Additional Power Needs for PECVD

Plasma-Enhanced CVD (PECVD) uses plasma to enable deposition at lower temperatures. While the SCR power supply is still used for substrate heating, these systems require a separate, secondary power supply—typically a Radio Frequency (RF) generator—to create and sustain the plasma field itself.

Absolute Precision for MOCVD

Metal-Organic CVD (MOCVD) is used to create highly complex, layered structures for optoelectronics like LEDs and laser diodes. The chemical reactions are exquisitely sensitive to temperature variations. Here, the ultra-precise, PLC-driven control of the SCR power supply is not just beneficial, but an absolute necessity for fabricating functional devices.

Making the Right Choice for Your Goal

Understanding the power supply's function is key to evaluating any CVD system for your specific needs.

- If your primary focus is research and development: Your priority is the programmability and resolution of the PLC and SCR controller, as this will determine your ability to experiment with novel thermal profiles.

- If your primary focus is high-volume production: Your priority is the robustness and reliability of the system, particularly the efficiency of the liquid cooling, which dictates uptime and process consistency.

- If you are specifying or purchasing a new system: Scrutinize the power supply specifications as much as the reaction chamber, as its stability and control resolution will ultimately define the performance limits of the entire tool.

Ultimately, the power supply is the engine of the CVD furnace, and its precise control over thermal energy is what makes the synthesis of modern advanced materials possible.

Summary Table:

| Component | Key Function | Importance in CVD Process |

|---|---|---|

| SCR Power Supply | Provides low-voltage, high-current power with phase-angle firing | Enables precise temperature control for uniform thin films |

| PLC Controller | Manages temperature profiles and feedback loops | Allows complex, repeatable heating recipes |

| Liquid Cooling | Dissipates waste heat from power electronics | Ensures system stability and reliability during high-temperature runs |

| Additional RF Supply (for PECVD) | Generates plasma for lower-temperature deposition | Supports PECVD processes with separate power needs |

Ready to enhance your lab's capabilities with advanced CVD furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace systems, including CVD/PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for superior thin film deposition and material synthesis. Contact us today to discuss how our tailored power supply systems can optimize your research or production processes!

Visual Guide

Related Products

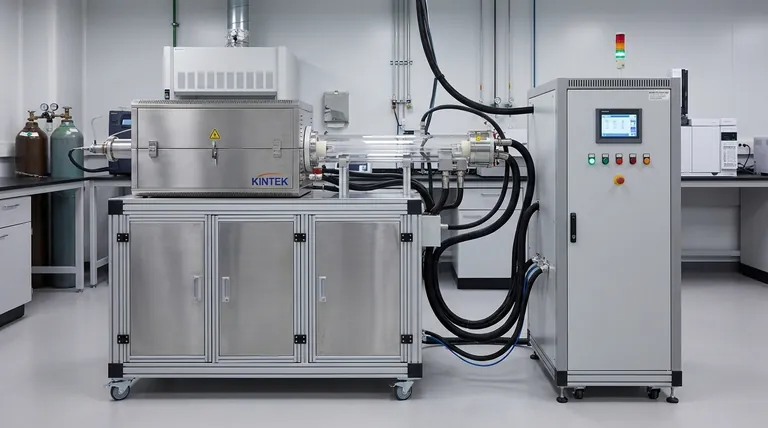

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis

- How does the gas control system in a CVD tube furnace enhance its functionality? Achieve Precise Thin Film Deposition

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility