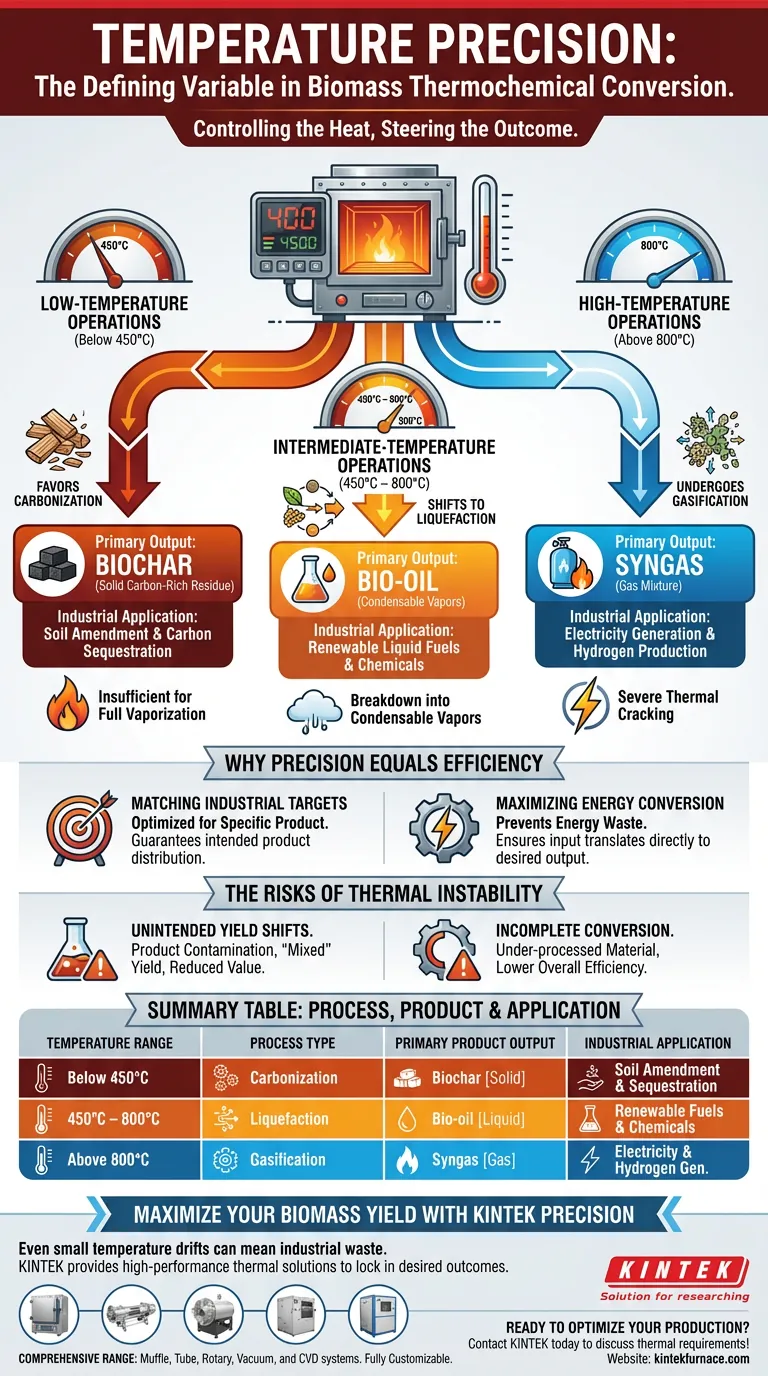

Temperature is the defining variable that dictates the outcome of biomass thermochemical conversion. In industrial high-temperature furnaces, the specific heat level applied effectively steers the chemical reaction. Precision is critical because it determines whether the final output is a solid (biochar), a liquid (bio-oil), or a gas (syngas).

Precise temperature control acts as a selector switch for reaction pathways. By maintaining specific thermal zones, operators can maximize the yield of desired products while optimizing overall energy conversion efficiency.

The Mechanics of Product Distribution

Low-Temperature Operations (Below 450°C)

When the furnace temperature is maintained below 450°C, the process favors carbonization.

In this range, the thermal energy is insufficient to fully vaporize the biomass structure. Consequently, the primary output becomes biochar, a solid carbon-rich residue.

Intermediate-Temperature Operations (450°C – 800°C)

Increasing the temperature to a window between 450°C and 800°C shifts the reaction toward liquefaction.

At these levels, the biomass components break down into condensable vapors. This effectively maximizes the production of bio-oil, which is the target for many liquid fuel applications.

High-Temperature Operations (Above 800°C)

When temperatures exceed 800°C, the reaction undergoes gasification.

The intense heat causes severe thermal cracking of the biomass. This shifts the primary output away from liquids and solids, converting the material almost entirely into syngas.

Why Precision Equals Efficiency

Matching Industrial Targets

Industrial facilities generally optimize for a specific product, not a random mixture.

High-precision control ensures the furnace environment remains locked within the specific thermal window required for that product. This guarantees that the product distribution matches the intended industrial targets.

Maximizing Energy Conversion

Inaccurate temperature control results in energy waste.

If the goal is bio-oil, heating beyond 800°C wastes energy by converting valuable liquid potential into gas. Precision ensures input energy translates directly into the desired output form.

The Risks of Thermal Instability

Unintended Yield Shifts

A lack of precision leads to product contamination.

Fluctuating temperatures create a "mixed" yield, where bio-oil might be degraded by syngas or contaminated with excess char. This reduces the purity and market value of the final product.

Incomplete Conversion

Drifting below target temperatures can result in under-processed material.

If the furnace fails to hold the minimum required heat, the biomass may not fully convert. This leaves unreacted material that lowers the overall efficiency of the operation.

Aligning Temperature with Production Goals

Success in thermochemical conversion depends on strict adherence to the thermal thresholds of your desired output.

- If your primary focus is Biochar Production: Maintain furnace temperatures strictly below 450°C to maximize solid carbon retention.

- If your primary focus is Bio-oil Synthesis: Stabilize operations between 450°C and 800°C to facilitate optimal liquefaction.

- If your primary focus is Syngas Generation: Push temperatures above 800°C to ensure complete gasification of the biomass.

Ultimately, precision in temperature control is the difference between a random chemical reaction and a targeted, efficient industrial process.

Summary Table:

| Temperature Range | Process Type | Primary Product Output | Industrial Application |

|---|---|---|---|

| Below 450°C | Carbonization | Biochar (Solid) | Soil amendment & carbon sequestration |

| 450°C – 800°C | Liquefaction | Bio-oil (Liquid) | Renewable liquid fuels & chemicals |

| Above 800°C | Gasification | Syngas (Gas) | Electricity generation & hydrogen production |

Maximize Your Biomass Yield with KINTEK Precision

In the world of thermochemical conversion, even a small temperature drift can be the difference between a high-value product and industrial waste. KINTEK provides the high-performance thermal solutions you need to lock in your desired outcomes.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab and industrial high-temperature furnaces are fully customizable to meet your unique biomass processing needs, ensuring stable thermal zones and superior energy conversion efficiency.

Ready to optimize your production? Contact KINTEK today to discuss your specific thermal requirements with our engineering team!

Visual Guide

References

- Jean de Dieu Marcel Ufitikirezi, Luboš Smutný. Agricultural Waste Valorization: Exploring Environmentally Friendly Approaches to Bioenergy Conversion. DOI: 10.3390/su16093617

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Which methanol dissociation reaction is appropriate for carburizing or neutral hardening? Ensure Clean, Controlled Heat Treatment

- What are the main application fields of atmosphere furnaces? Essential for Metal, Electronics, and R&D

- Why is a controlled atmosphere sintering furnace required for porous metal? Ensure Strength and Prevent Oxidation

- Why is high-temperature annealing in an Air Atmosphere Furnace necessary for YAG ceramics after vacuum sintering? Achieve Optical Clarity and Mechanical Stability

- What role does an atmosphere box furnace play in material synthesis and preparation? Unlock Precision in Advanced Material Creation

- What gases are commonly used in gas quenching applications? Optimize Cooling for Superior Metal Properties

- What is the mechanism by which a reducing atmosphere improves Mn-Zn ferrite performance? Unlocking Magnetic Excellence

- What type of pumps are used in low vacuum atmosphere furnaces? Rotary Vane Pumps for Efficient Heat Treatment