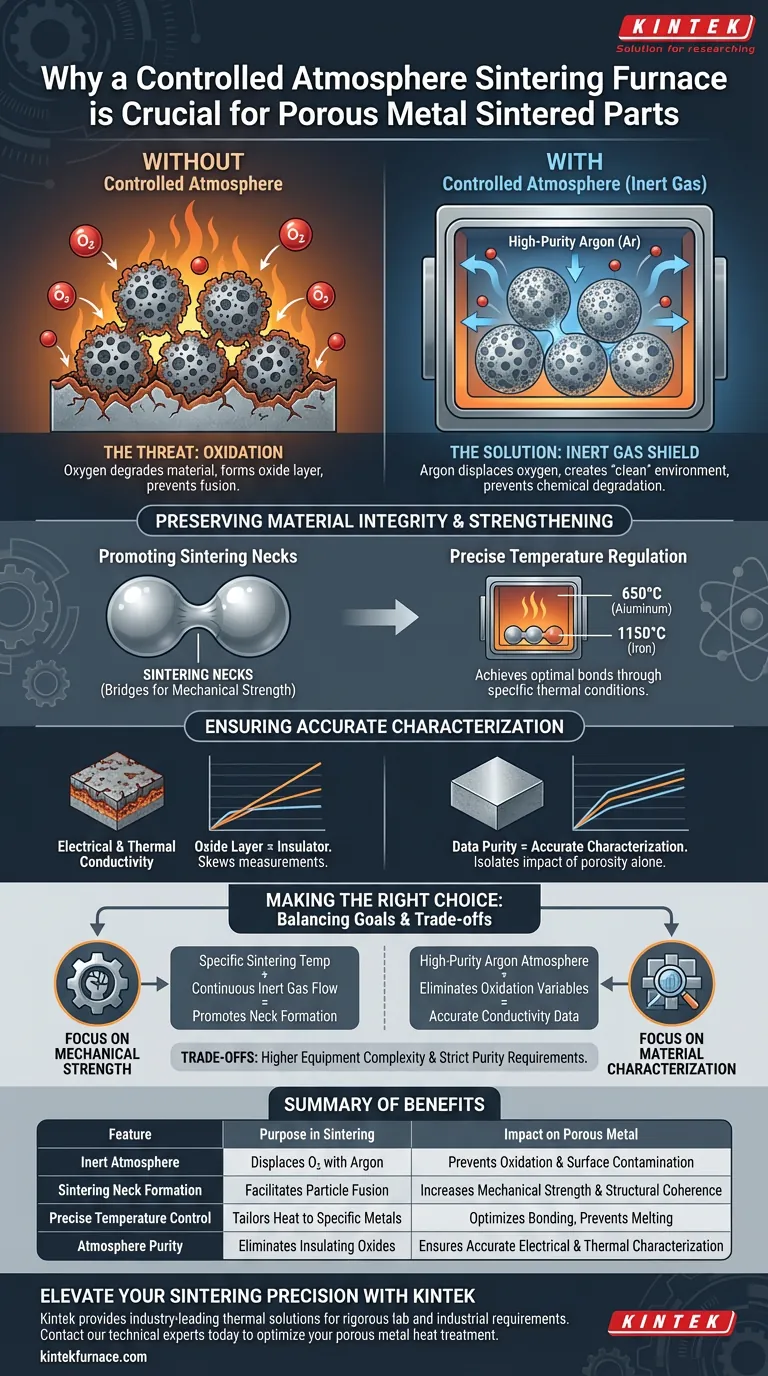

The primary necessity for a controlled atmosphere sintering furnace lies in its ability to isolate metal particles from oxygen while applying the intense heat required for bonding. Without this controlled environment, typically utilizing high-purity argon, metal particles would oxidize rather than fuse, compromising the structural and functional integrity of the final part.

Core Takeaway To achieve reliable mechanical strength in porous metal parts, you must eliminate oxidation during the heating process. A controlled atmosphere ensures that the formation of sintering necks and the resulting material properties are influenced only by the intended porosity, not by atmospheric contamination.

Preserving Material Integrity

The Threat of Oxidation

At elevated temperatures, metal particles are highly reactive to oxygen. Without protection, an oxide layer forms on the surface of the particles.

This oxidation acts as a barrier, preventing the metal from properly fusing. It degrades the material's inherent properties before the part is even finished.

The Shielding Role of Inert Gas

To act as a countermeasure, these furnaces utilize a controlled atmosphere, often composed of high-purity argon gas.

This inert gas displaces oxygen within the chamber. It creates a "clean" environment where the metal can undergo high-thermal treatment without chemically degrading.

Mechanisms of Strengthening

Promoting Sintering Necks

The ultimate goal of this heat treatment is mechanical strength. This is achieved through the formation of sintering necks.

These "necks" are bridges that form between individual metal particles, fusing them into a coherent structure. A controlled atmosphere is required to facilitate the clean surface contact necessary for these necks to grow.

Precise Temperature Regulation

Achieving these bonds requires specific thermal conditions tailored to the metal type.

For example, the furnace must maintain distinct temperatures such as 650°C for aluminum or 1150°C for iron. The furnace system regulates these temperatures precisely to optimize the sintering outcome for the specific material matrix.

Ensuring Accurate Characterization

Isolating the Impact of Porosity

When analyzing porous metal parts, engineers often measure effective electrical and thermal conductivity.

If the metal oxidizes, the oxide layer acts as an insulator, skewing these measurements.

Removing Variables

By preventing oxidation, the controlled atmosphere ensures data purity.

It guarantees that any changes in conductivity are the result of porosity alone. This allows researchers to accurately characterize how void spaces impact the material's performance without interference from surface impurities.

Understanding the Trade-offs

Equipment Complexity

While a standard muffle furnace can induce structural changes at the molecular level, it lacks the sophisticated gas control of a sintering furnace.

Using a controlled atmosphere system introduces higher complexity regarding gas flow management and seal integrity compared to open-air heat treatment.

Strict Purity Requirements

The effectiveness of the process is entirely dependent on the quality of the atmosphere.

If the argon gas is not of high purity, or if there is a leak in the system, partial oxidation can still occur. This leads to inconsistent mechanical strength and unreliable conductivity data.

Making the Right Choice for Your Goal

To select the correct heat treatment strategy, consider the material properties you are trying to optimize.

- If your primary focus is Mechanical Strength: Ensure your furnace can reach the specific sintering temperature (e.g., 1150°C for iron) while maintaining a continuous flow of inert gas to promote neck formation.

- If your primary focus is Material Characterization: Use a high-purity argon atmosphere to eliminate oxidation variables, ensuring your conductivity data reflects only the impact of the material's porosity.

Success in sintering porous metals depends not just on heat, but on the absolute purity of the environment in which that heat is applied.

Summary Table:

| Feature | Purpose in Sintering | Impact on Porous Metal |

|---|---|---|

| Inert Atmosphere | Displaces oxygen using high-purity argon | Prevents oxidation and surface contamination |

| Sintering Neck Formation | Facilitates particle fusion | Increases mechanical strength and structural coherence |

| Precise Temperature Control | Tailors heat to specific metals (e.g., 1150°C for iron) | Optimizes material bonding without melting |

| Atmosphere Purity | Eliminates insulating oxide layers | Ensures accurate electrical and thermal characterization |

Elevate Your Sintering Precision with KINTEK

Don't let oxidation compromise your material integrity. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed for rigorous lab and industrial requirements. Backed by expert R&D and precision manufacturing, our high-temp furnaces are fully customizable to meet your specific gas flow and atmospheric purity needs.

Ready to optimize your porous metal heat treatment? Contact our technical experts today to find the perfect furnace for your application.

Visual Guide

References

- J. M. Montes, Fátima Ternero. Effective Electrical and Thermal Conductivities of Porous Sintered Metallic Compacts. DOI: 10.1007/s11661-025-07876-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What role does an argon atmosphere play when sintering WC-Co-Ni alloys? Achieve Near-Theoretical Density

- Why are furnace atmospheres tailored for specific processes? To Control Chemical Reactions for Superior Results

- Which industries benefit from the versatility of retort furnaces? Unlock Precise Heat and Atmosphere Control

- What is the purpose of using a two-step homogenization furnace treatment for Al-Cu-Li alloy ingots? Optimize Plasticity

- How does a continuous controlled atmosphere furnace operate? Unlock High-Volume Precision in Material Processing

- Why use a resistance heating furnace for Hf chlorination? Ensure Stable HfO2 Coating Growth & Precursor Flow

- Why use multi-stage temperature control for REBCO pyrolysis? Prevent 75% Shrinkage Cracks and Ensure Film Density

- Why is temperature and atmosphere monitoring critical in furnace operations? Ensure Safety and Quality in Heat Treatment