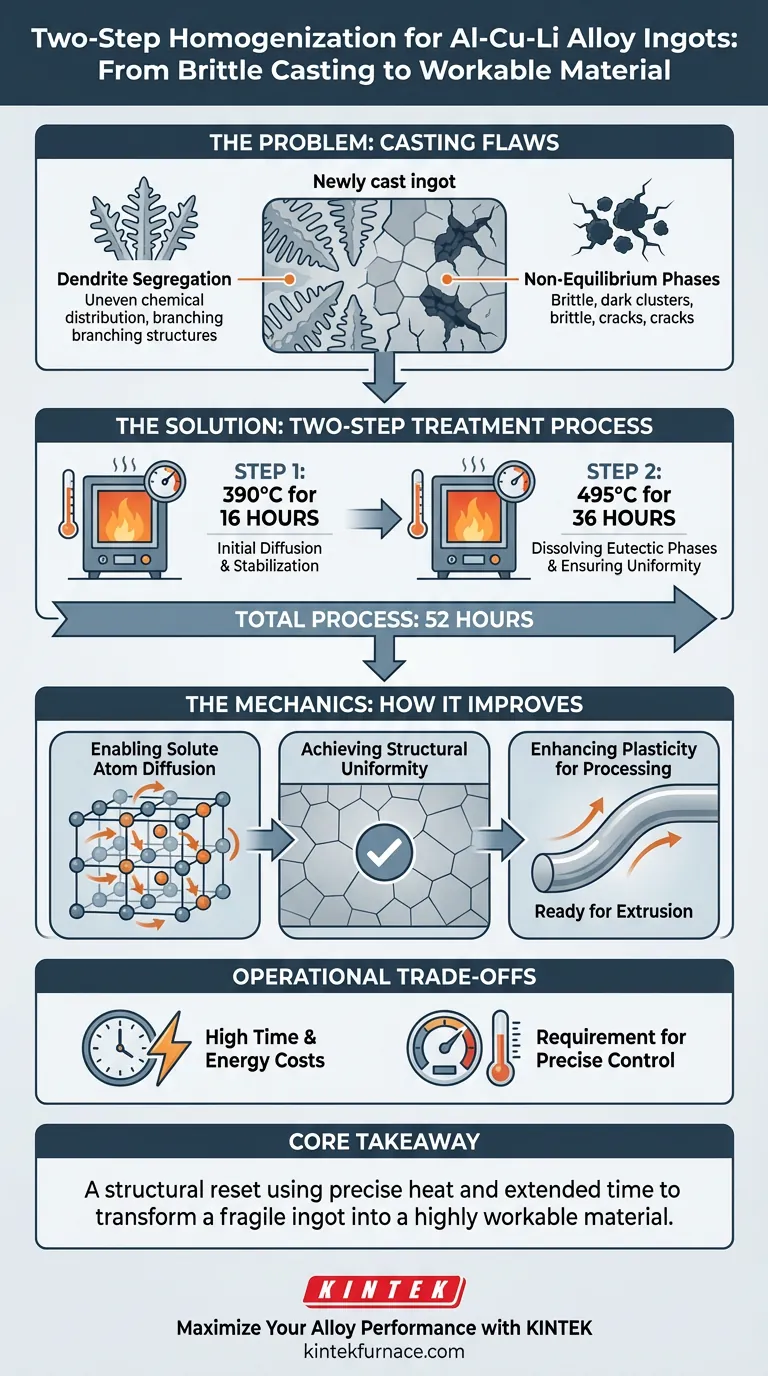

The primary purpose of a two-step homogenization furnace treatment for Al-Cu-Li alloy ingots is to correct structural irregularities created during the casting process. By subjecting the ingot to specific thermal stages, such as 390°C for 16 hours followed by 495°C for 36 hours, the treatment eliminates non-equilibrium eutectic phases and dendrite segregation. This ensures the material achieves the necessary uniformity and plasticity to survive subsequent mechanical processing, such as extrusion.

Core Takeaway Casting naturally leaves Al-Cu-Li alloys with a brittle, uneven internal structure. The two-step homogenization process acts as a structural reset, utilizing precise heat and extended time to diffuse solute atoms, thereby transforming a fragile ingot into a highly workable material ready for extrusion.

Addressing the Flaws of Casting

Eliminating Dendrite Segregation

When Al-Cu-Li alloys are cast, the cooling process is rarely perfectly uniform. This leads to dendrite segregation, where chemical elements distribute unevenly across the metal's grain structure.

The two-step treatment targets these segregated areas. It forces the material to re-balance, ensuring a consistent chemical composition throughout the ingot.

Dissolving Non-Equilibrium Phases

Casting often results in the formation of non-equilibrium eutectic phases. These are brittle structures that can compromise the integrity of the alloy.

The specific thermal regimen is designed to dissolve these unwanted phases back into the solid solution. This eliminates potential fracture points within the metal.

The Mechanics of Improvement

Enabling Solute Atom Diffusion

The effectiveness of this treatment relies on extended soaking times (e.g., 52 hours total in the cited example).

Holding the ingot at high temperatures provides the energy required for solute atoms to move. This diffusion process allows atoms to migrate from areas of high concentration to areas of low concentration.

Achieving Structural Uniformity

The ultimate goal of diffusion is a highly uniform internal microstructure.

Instead of a chaotic mix of brittle phases and segregated elements, the ingot becomes a homogeneous solid. This uniformity is critical for consistent performance in finished parts.

Enhancing Plasticity for Processing

A uniform structure directly translates to improved plasticity.

Without this treatment, the ingot would likely crack or fail under the high stress of extrusion. The homogenization process softens the alloy sufficiently to allow for successful deformation.

Understanding the Operational Trade-offs

High Time and Energy Costs

The two-step process described requires significant resources, specifically an extended soaking time totaling over 50 hours.

This represents a major bottleneck in production throughput and a substantial energy cost compared to single-step or shorter treatments.

Requirement for Precise Control

The reference highlights the need for precise temperature control (e.g., distinct steps at 390°C and 495°C).

Fluctuations in furnace temperature can fail to dissolve the eutectic phases or, conversely, overheat the alloy. This necessitates advanced furnace equipment and strict process monitoring.

Making the Right Choice for Your Goal

To determine if this rigorous treatment is required for your specific application, consider your downstream processing needs:

- If your primary focus is Extrusion Viability: You must implement the full two-step cycle to ensure the ingot has sufficient plasticity to prevent cracking during deformation.

- If your primary focus is Microstructural Consistency: You should prioritize the extended soaking times to guarantee the complete diffusion of solute atoms and the elimination of segregation.

The two-step homogenization is not merely a heating cycle; it is a critical conditioning phase that dictates the manufacturability of the alloy.

Summary Table:

| Stage | Temperature | Duration | Primary Objective |

|---|---|---|---|

| Step 1 | 390°C | 16 Hours | Initial diffusion and stabilization of structure |

| Step 2 | 495°C | 36 Hours | Dissolving eutectic phases & ensuring uniformity |

| Total Process | N/A | 52 Hours | Achieving maximum plasticity for extrusion |

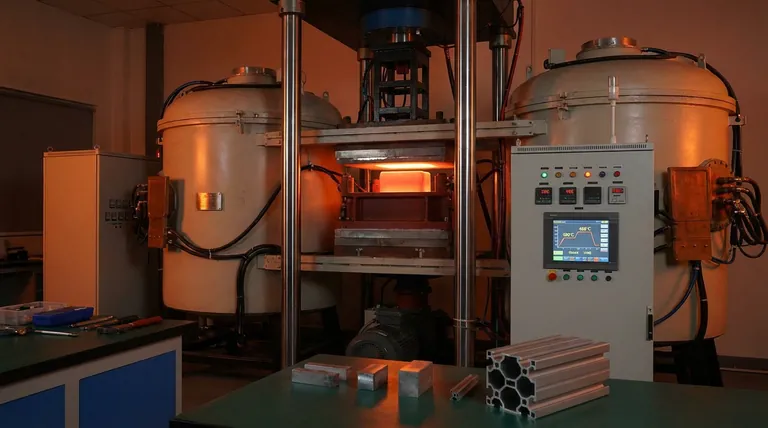

Maximize Your Alloy Performance with KINTEK

Don't let structural irregularities compromise your material integrity. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to handle the rigorous 50+ hour soaking cycles required for Al-Cu-Li homogenization. Our lab high-temp furnaces are fully customizable to meet your unique thermal processing needs, ensuring perfect temperature control and structural uniformity every time.

Ready to elevate your extrusion success? Contact us today to find your custom furnace solution!

Visual Guide

References

- Meiqi Wang, Baiqing Xiong. Influence of Zn Addition on the Aging Precipitate Behavior and Mechanical Properties of Al-Cu-Li Alloy. DOI: 10.3390/ma17071562

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What industries benefit the most from using argon in furnaces? Ensure Material Integrity in High-Stakes Applications

- What is the function of a vertical gas mixing furnace during the annealing of orthopyroxene? Achieve Precise Stability

- How does a specialized ion nitriding furnace achieve gradient hardening on TC4 titanium? Boost Surface Wear Resistance

- How does the box type annealing atmosphere furnace improve production efficiency? Boost Throughput and Cut Costs

- Why is high-temperature annealing in an Air Atmosphere Furnace necessary for YAG ceramics after vacuum sintering? Achieve Optical Clarity and Mechanical Stability

- How is an atmosphere furnace used in material science research? Unlock Precise Material Control and Synthesis

- Why use multi-stage temperature control for REBCO pyrolysis? Prevent 75% Shrinkage Cracks and Ensure Film Density

- Why is an inert atmosphere important in heat treatment processes? Prevent Oxidation and Ensure Material Integrity