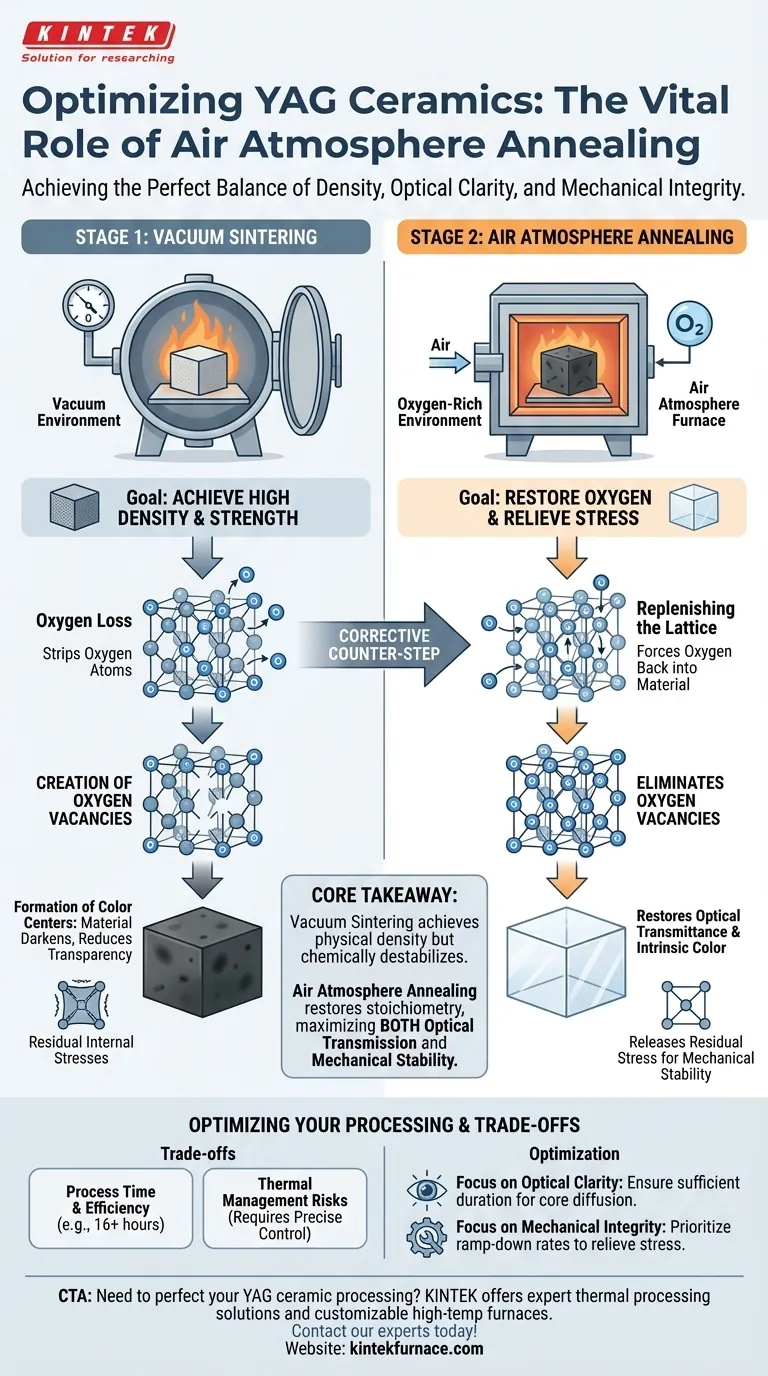

High-temperature annealing in an air atmosphere is essential because vacuum sintering, while effective for densification, strips oxygen atoms from the ceramic lattice. This creates "oxygen vacancies" that darken the material and reduce transparency. The annealing process utilizes an oxygen-rich environment to replenish these atoms, eliminate the dark defects, and relieve residual internal stresses generated during the sintering phase.

Core Takeaway Vacuum sintering achieves the necessary physical density but chemically destabilizes the material by causing oxygen loss. Air atmosphere annealing is the corrective counter-step required to restore the ceramic's stoichiometry, maximizing both optical transmission and mechanical stability.

The Consequence of Vacuum Sintering

The Trade-off for Density

A vacuum furnace is the standard environment for sintering YAG ceramics because it effectively removes porosity. This ensures the final product achieves high density, hardness, and mechanical strength.

The Creation of Oxygen Vacancies

However, the vacuum environment creates a chemical imbalance. The low pressure causes the ceramic to lose oxygen atoms from its crystal structure.

Formation of Color Centers

These missing atoms leave behind "oxygen vacancies," which act as color centers. Instead of being transparent, these defects absorb light and cause the ceramic to appear dark or discolored.

How Air Atmosphere Annealing Fixes the Material

Replenishing the Lattice

High-temperature annealing in an Air Atmosphere Furnace exposes the ceramic to an oxygen-rich environment. This process forces oxygen back into the material, effectively filling the vacancies created during vacuum sintering.

Restoring Optical Transmittance

By eliminating the oxygen vacancy defects, the annealing process removes the color centers. This restores the intrinsic color of the ceramic and significantly improves its light transmittance, making it suitable for optical applications.

Releasing Residual Stress

Beyond chemistry, the sintering and hot-pressing processes generate significant internal mechanical stress. Subjecting the ceramic to prolonged heat treatment (e.g., 16 hours) allows the material structure to relax.

enhancing Mechanical Stability

This relaxation releases internal tension without altering the shape. The result is a ceramic that is not only clear but also mechanically stable and less prone to spontaneous cracking or failure.

Understanding the Trade-offs

Process Time and Efficiency

While annealing is necessary for optical quality, it significantly adds to the total processing time. A typical cycle can last 16 hours or more to ensure oxygen diffuses throughout the entire bulk of the material.

Thermal Management Risks

If the annealing temperature is uncontrolled or the cooling phase is too rapid, new thermal stresses can be introduced. Precise temperature control is required to repair defects without reversing the gains made in mechanical stability.

Optimizing Your Ceramic Processing

To achieve the highest quality YAG ceramics, you must view sintering and annealing as coupled, non-negotiable stages.

- If your primary focus is Optical Clarity: Ensure the annealing duration is sufficient to allow oxygen diffusion into the core of the ceramic, fully eliminating color centers.

- If your primary focus is Mechanical Integrity: Prioritize the annealing cycle's ramp-down rates to ensure residual internal stresses are fully relieved without inducing thermal shock.

True high-performance YAG ceramics are defined by the balance of vacuum-induced density and air-restored clarity.

Summary Table:

| Process Stage | Primary Goal | Key Outcome |

|---|---|---|

| Vacuum Sintering | Achieve high density | High mechanical strength, but creates oxygen vacancies (darkening) |

| Air Atmosphere Annealing | Restore oxygen & relieve stress | Eliminates color centers, enhances optical transmittance, and improves mechanical stability |

Need to perfect your YAG ceramic processing?

Our expertise in thermal processing ensures your materials achieve the ideal balance of density, optical clarity, and mechanical integrity. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs like precise YAG annealing cycles.

Contact our experts today to discuss how our furnaces can optimize your ceramic production.

Visual Guide

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the primary functions of industrial-grade constant temperature furnaces for NiCoCrAlY oxidation kinetics?

- How does the heating chamber in an atmosphere furnace function? Master Heat Treatment for Superior Results

- How does an inert atmosphere furnace work? Master Controlled Heating for Oxidation-Free Results

- What does nitrogen do in a furnace? Create an Inert, Oxygen-Free Atmosphere for Superior Results

- How are atmosphere furnaces utilized in semiconductor manufacturing? Essential for Annealing, Diffusion, and CVD Processes

- How does the furnace atmosphere impact the final properties of a material? Master Material Engineering with Controlled Atmospheres

- How are inert atmosphere furnaces sealed and prepared for operation? Ensure Process Integrity and Prevent Oxidation

- Why is a high-precision annealing furnace necessary for optical fibers? Control Nanoparticle Growth for Peak Performance