Precision is the defining factor in the post-treatment of optical fibers containing silver nanoparticles. A high-precision annealing furnace is necessary to maintain an exacting thermal environment—specifically around 600°C for one hour—to trigger the chemical reduction and aggregation of silver ions within the glass matrix. Without this rigorous stability, it is impossible to control the formation of nanoparticles or the resulting optical properties of the fiber.

The furnace is not merely heating the glass; it is orchestrating a precise chemical reaction. The accuracy of temperature and duration directly dictates the nucleation of silver nanoparticles, which determines the fiber's Localized Surface Plasmon Resonance (LSPR) and its specific scattering characteristics.

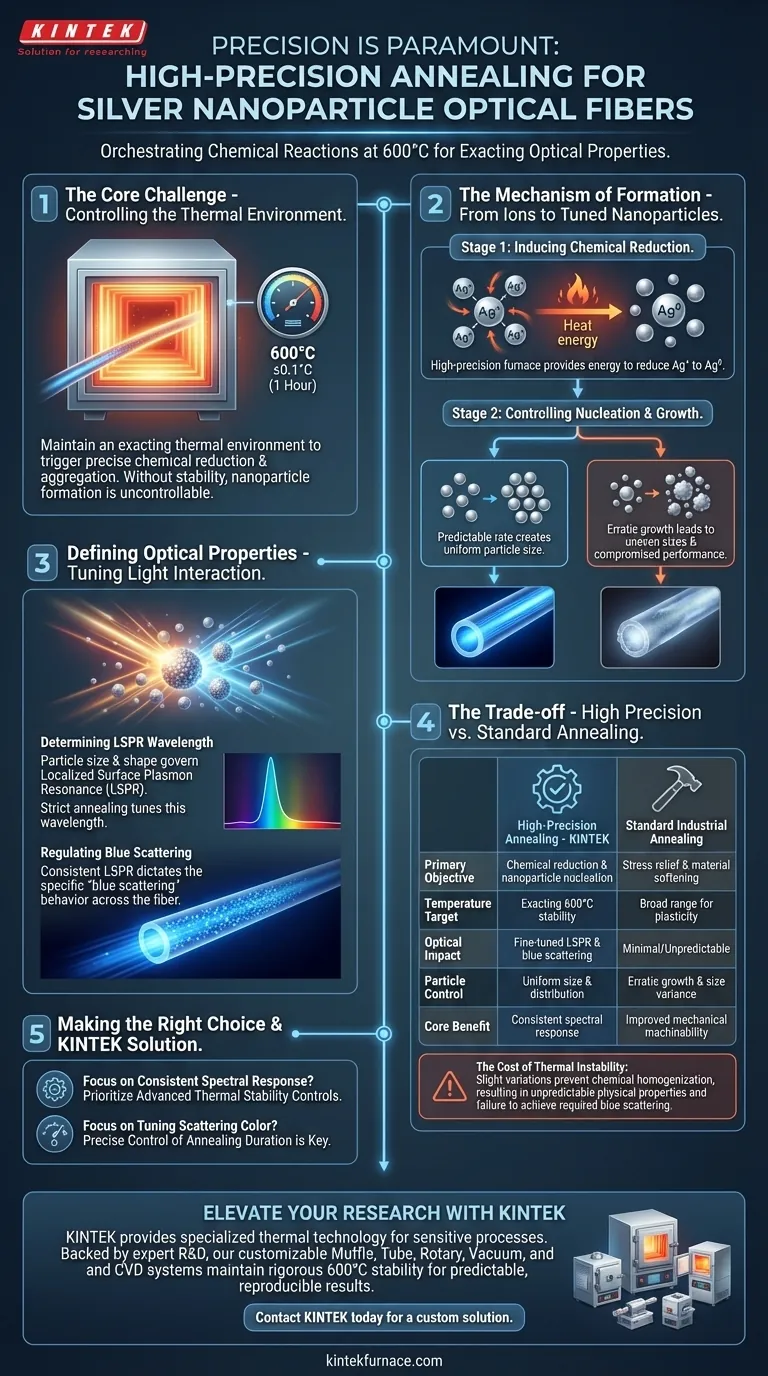

The Mechanism of Nanoparticle Formation

Inducing Chemical Reduction

The primary goal of this annealing process is to alter the chemical state of the silver within the fiber.

The high-precision furnace provides the energy required to reduce silver ions ($Ag^+$) into elemental silver ($Ag^0$). This chemical reduction is the foundational step for creating the desired optical effects.

Controlling Nucleation and Growth

Once reduced, the silver atoms must aggregate to form nanoparticles.

This stage is comprised of nucleation (the birth of new particles) and growth (the increase in particle size). Precise thermal control ensures these two phases happen at a predictable rate.

If the temperature fluctuates, the growth rate becomes erratic. This leads to uneven particle sizes throughout the fiber, compromising its performance.

Defining Optical Properties

Determining the LSPR Wavelength

The physical size and shape of the silver nanoparticles govern how they interact with light.

This interaction is known as Localized Surface Plasmon Resonance (LSPR). By strictly controlling the annealing time and temperature, you are effectively "tuning" the LSPR wavelength.

Regulating Blue Scattering

The LSPR directly influences the spectral characteristics of the fiber.

specifically, the process regulates the blue scattering behavior of the optical fiber. A high-precision furnace ensures that this scattering effect is consistent and reproducible across the entire length of the fiber.

Understanding the Trade-offs

High Precision vs. General Annealing

It is important to distinguish this process from standard industrial annealing.

As noted in general mechanical applications, standard annealing is often used simply to soften materials, remove residual stress, or improve plasticity. While stress removal is a beneficial side effect for optical fibers, it is not the primary objective here.

The Cost of Thermal Instability

Using a standard, low-precision furnace introduces significant risk.

If the "thermal history" of the fiber varies even slightly, the chemical composition will not be homogenized. This results in unpredictable physical properties and a failure to achieve the specific blue scattering spectrum required for the application.

Making the Right Choice for Your Goal

To ensure your optical fiber performs as intended, you must align your equipment capabilities with your specific processing objectives.

- If your primary focus is consistent spectral response: Prioritize a furnace with advanced thermal stability controls to ensure uniform nanoparticle size distribution.

- If your primary focus is tuning the scattering color: Focus on the precise control of the annealing duration, as the time spent at 600°C directly impacts particle growth and the resulting LSPR shift.

Mastering the thermal environment is the only way to transition from raw materials to a functional, high-performance optical component.

Summary Table:

| Feature | High-Precision Annealing | Standard Industrial Annealing |

|---|---|---|

| Primary Objective | Chemical reduction & nanoparticle nucleation | Stress relief & material softening |

| Temperature Target | Exacting 600°C stability | Broad range for plasticity |

| Optical Impact | Fine-tuned LSPR & blue scattering | Minimal/Unpredictable |

| Particle Control | Uniform size & distribution | Erratic growth & size variance |

| Core Benefit | Consistent spectral response | Improved mechanical machinability |

Elevate Your Optical Fiber Research with KINTEK

Precision is the difference between a raw material and a high-performance optical component. KINTEK provides the specialized thermal technology required for sensitive processes like silver nanoparticle aggregation.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to maintain the rigorous 600°C stability your lab demands. Whether you are tuning LSPR wavelengths or perfecting blue scattering effects, our high-temp furnaces ensure your chemical reactions are predictable and reproducible.

Ready to achieve superior thermal accuracy? Contact KINTEK today for a custom solution.

Visual Guide

References

- Jan Schröder, Lothar Wondraczek. Functional Optical Fibers with Tailored Side Emission from Modified Rod‐in‐Tube Preforms. DOI: 10.1002/adpr.202500018

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a laboratory high-temperature annealing furnace necessary after the initial formation of a perovskite thin film?

- What metallurgical processes benefit from atmosphere furnace treatment? Boost Quality with Controlled Heat Treatment

- What role does atmosphere control play in ruthenium loading for catalyst synthesis? Master Precision Kinetics

- What are the purposes of inert atmospheres in heat treatment? Enhance Metal Quality and Safety

- How is a reducing atmosphere utilized in metal processing? Prevent Oxidation and Enhance Metal Quality

- Why is a high-purity argon protective environment necessary during the mechanical alloying of Cu-Al2O3 powder?

- What properties of argon make it suitable for heat treatment processes? Discover Its Inert Benefits for Metals

- What is the function of a salt bath furnace in the preparation of ADI? Achieve Superior Structural Transformation