Fundamentally, any high-temperature metallurgical process where the surface chemistry of a part must be protected or intentionally modified benefits from a controlled atmosphere furnace. This includes common heat treatments such as annealing, hardening, and tempering, as well as surface modification processes like carburizing, nitriding, brazing, and sintering. The controlled atmosphere is not an afterthought; it is a critical process variable that dictates the final quality and properties of the component.

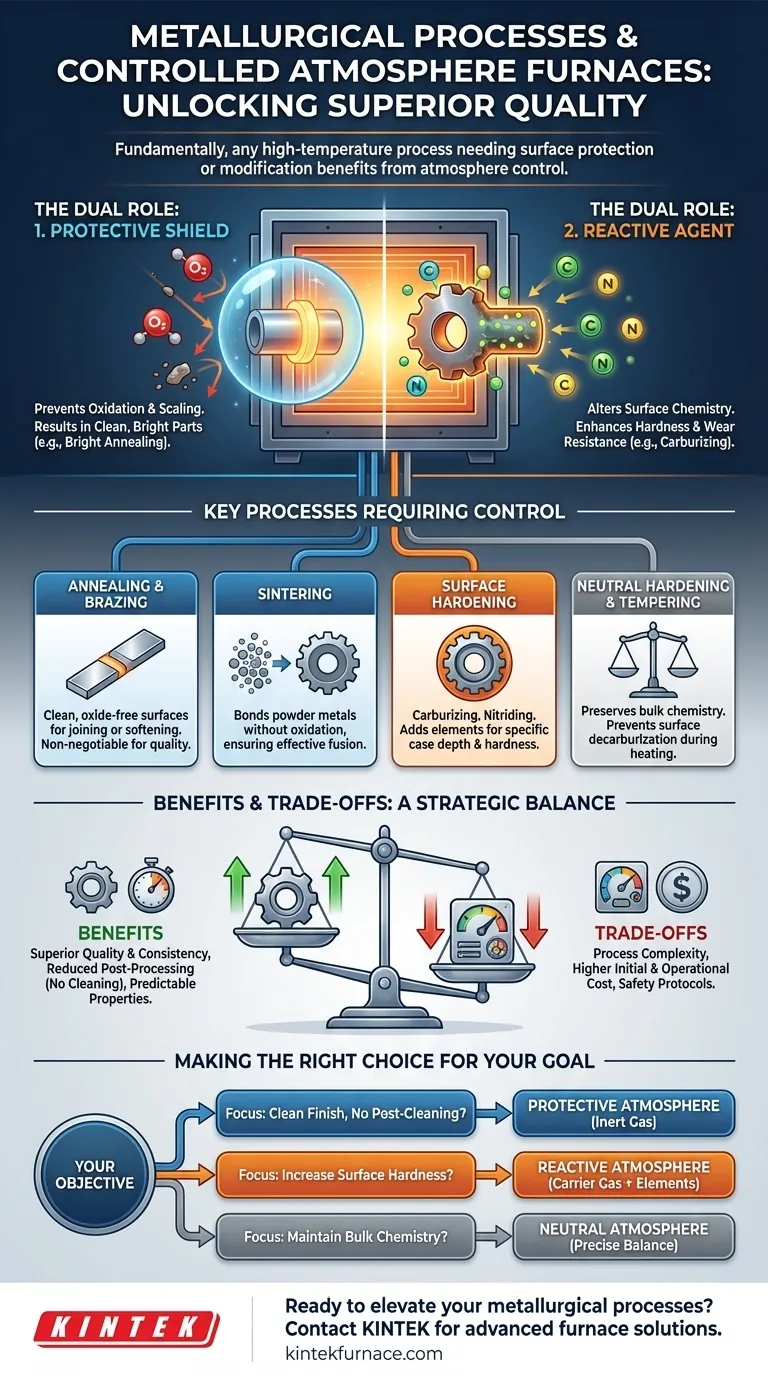

A furnace atmosphere serves one of two critical purposes: it acts as a protective shield to prevent harmful reactions like oxidation at high temperatures, or it functions as a reactive agent to intentionally alter the surface chemistry of the metal for enhanced performance.

The Dual Role of a Controlled Atmosphere

Understanding why atmosphere control is essential comes down to recognizing that at high temperatures, metal surfaces become highly reactive. Leaving them exposed to ambient air can ruin the part or negate the purpose of the heat treatment.

Function 1: To Protect the Material's Surface

At elevated temperatures, the oxygen in the air will readily react with most metals, forming oxides on the surface. This is known as oxidation or scaling.

A protective atmosphere, typically composed of inert or non-oxidizing gases, displaces the air and creates a shield around the part. This prevents oxidation, discoloration, and surface decarburization (the loss of carbon from steel).

The result is a clean, often shiny part that requires little to no post-process cleaning, a process known as bright annealing or bright hardening.

Function 2: To Actively Change the Material's Surface

In some processes, the atmosphere is the primary tool for changing the material's properties. It acts as a carrier gas, delivering specific elements to the surface of the part to create a hardened case.

For example, in carburizing, the atmosphere is rich in carbon. This carbon diffuses into the surface of the steel, dramatically increasing its surface hardness and wear resistance while leaving the core tough and ductile.

Other processes like nitriding (adding nitrogen) and carbonitriding (adding carbon and nitrogen) follow the same principle, using the atmosphere as a reactive medium to engineer the component's surface.

Key Processes Requiring Atmosphere Control

Different metallurgical goals demand specific atmospheric conditions. Here are the most common applications and why they depend on atmosphere control.

Annealing and Brazing

For processes like bright annealing (softening metal) and brazing (joining metals), the goal is a clean, oxide-free surface. Any oxidation can inhibit the joining process or compromise the finish of the final part. A protective, inert atmosphere is non-negotiable for high-quality results.

Surface Hardening Processes

These processes use a reactive atmosphere to create a "case" of hardened material on the component's surface.

- Carburizing: Adds carbon to the surface of low-carbon steel.

- Nitriding: Adds nitrogen to create extremely hard nitrides on the surface.

- Carbonitriding: Adds both carbon and nitrogen for a specific type of hard case.

In all these cases, the atmosphere's composition must be precisely controlled to achieve the correct case depth and hardness.

Neutral Hardening and Tempering

When hardening a steel part, the goal is often to heat it to a specific temperature without changing its surface chemistry. An uncontrolled atmosphere can cause both oxidation and decarburization, which would soften the surface and ruin the component.

A neutral atmosphere is carefully balanced so that it neither adds nor removes elements from the part's surface, ensuring the material's inherent carbon content is preserved during the heating cycle.

Sintering

Sintering is the process of forming a solid mass of material from powder using heat. A controlled atmosphere is critical to prevent the oxidation of the fine metal particles, which would inhibit them from bonding together effectively.

Understanding the Benefits and Trade-offs

Using an atmosphere furnace is an engineering decision with clear advantages but also requires a higher level of process control.

Benefit: Superior Quality and Consistency

By preventing oxidation and controlling surface reactions, you produce parts with superior surface finishes and consistent, predictable metallurgical properties. This reduces scrap rates and improves the performance and lifespan of the component.

Benefit: Reduced Post-Processing

A major advantage is the reduction or elimination of post-treatment cleaning steps. Parts emerging from a controlled atmosphere furnace are often clean and "bright," saving the significant time and cost associated with blasting, grinding, or chemical cleaning.

The Trade-off: Process Complexity and Cost

The primary trade-off is increased operational complexity. Atmosphere furnaces require sophisticated gas mixing and monitoring systems, safety protocols for handling flammable or inert gases, and the ongoing cost of the process gases themselves. This represents a higher initial and operational cost compared to a simple air furnace.

Making the Right Choice for Your Goal

Your specific objective dictates the type of atmospheric control you need.

- If your primary focus is a clean surface finish and avoiding post-process cleaning: A protective (inert) atmosphere for bright annealing, brazing, or sintering is the correct approach.

- If your primary focus is intentionally increasing surface hardness and wear resistance: A reactive atmosphere for processes like carburizing or nitriding is required.

- If your primary focus is maintaining the bulk chemistry of a part during heat treatment: A precisely balanced neutral atmosphere is critical for through-hardening to prevent surface decarburization.

Ultimately, mastering the furnace atmosphere provides direct control over the final quality, performance, and cost-effectiveness of your heat-treated components.

Summary Table:

| Process Type | Key Applications | Atmosphere Function |

|---|---|---|

| Annealing & Brazing | Bright annealing, metal joining | Protective (prevents oxidation) |

| Surface Hardening | Carburizing, nitriding, carbonitriding | Reactive (adds elements for hardness) |

| Neutral Hardening | Through-hardening, tempering | Neutral (preserves surface chemistry) |

| Sintering | Powder metal forming | Protective (prevents oxidation of particles) |

Ready to elevate your metallurgical processes with precise atmosphere control? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring superior quality, consistency, and reduced post-processing for your components. Contact us today to discuss how our tailored solutions can benefit your lab!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results