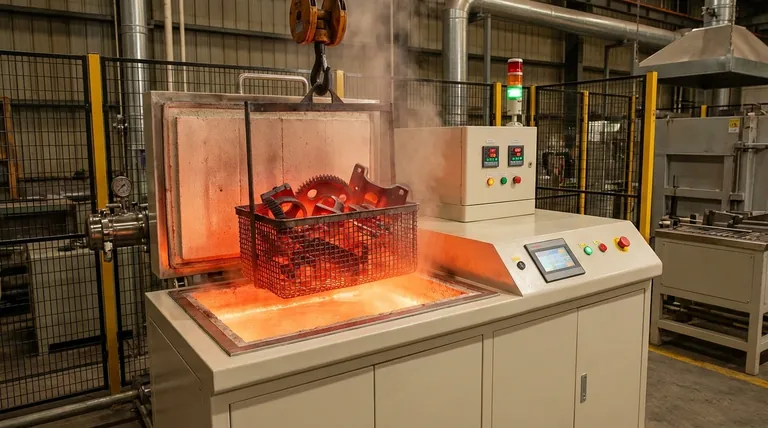

A salt bath furnace acts as the central mechanism for precise thermal control during the production of Austempered Ductile Iron (ADI). Its primary function is to facilitate preheating, austenitizing, and isothermal quenching with a level of uniformity that other heating methods struggle to match. By immersing the iron in molten salt, the furnace ensures rapid heat transfer and consistent temperatures, which are critical for achieving the material's unique mechanical properties.

The salt bath furnace is not merely a heating device; it is a tool for microstructural engineering. It enables the rapid quenching and strict temperature stability required to produce a defect-free matrix of acicular ferrite and high-carbon retained austenite.

The Critical Role of Thermal Uniformity

The production of ADI relies on exact phase transformations. The salt bath furnace serves as the control environment that dictates whether these transformations occur successfully.

Achieving Complete Structural Transformation

To create ADI, the ductile iron must first be heated to an austenitizing temperature of 910 °C.

The salt bath provides a highly uniform thermal environment, ensuring that complex or thick-walled parts are heated evenly throughout their cross-section. This uniformity guarantees that the iron achieves a complete structural transformation into austenite, laying the foundation for the final material properties.

Facilitating Rapid Quenching

Once austenitized, the iron must be cooled rapidly to the isothermal holding temperature.

The salt bath facilitates this rapid quenching, drastically reducing the temperature from 910 °C down to 360 °C. The liquid medium of the salt bath allows for faster heat extraction than air or vacuum furnaces, which is essential for the ADI process.

Preventing Undesired Phases

The speed and precision of the salt bath are vital for "freezing" the microstructure at the right moment.

By rapidly reaching and maintaining the 360 °C isothermal stage, the furnace prevents the precipitation of undesired phases, such as pearlite. This control ensures the final microstructure consists of the desired acicular ferrite and high-carbon retained austenite.

Understanding Process Sensitivity

While the salt bath furnace is highly effective, the process is sensitive to deviations. Understanding these sensitivities is crucial for consistent results.

The Risk of Thermal Lag

The primary pitfall in ADI preparation is a failure to quench rapidly enough.

If the transfer to the isothermal salt bath is delayed or the bath fails to extract heat quickly, the structural integrity of the iron is compromised. The salt bath is specifically utilized to mitigate this risk, but equipment maintenance is required to ensure heat transfer rates remain optimal.

Temperature Precision is Non-Negotiable

The difference between high-quality ADI and a failed batch often lies in temperature fluctuations.

The salt bath must maintain the 360 °C set point with extreme precision. Any significant drift during the isothermal hold can alter the balance of ferrite and austenite, degrading the mechanical performance of the final component.

Optimizing the ADI Production Process

To maximize the benefits of a salt bath furnace in ADI preparation, focus on the specific goals of your thermal cycle.

- If your primary focus is consistent hardness: Ensure the austenitizing soak at 910 °C is sufficient for the specific mass of your parts to achieve full saturation.

- If your primary focus is impact toughness: Prioritize the rapid transfer and stability at the 360 °C stage to strictly prevent the formation of non-ADI phases.

Leveraging the high thermal uniformity of a salt bath furnace is the most reliable method for consistently achieving the superior strength-to-weight ratio that defines Austempered Ductile Iron.

Summary Table:

| Process Stage | Temperature | Function of Salt Bath |

|---|---|---|

| Austenitizing | 910 °C | Ensures uniform heating and complete structural transformation. |

| Isothermal Quench | 910 °C to 360 °C | Facilitates rapid cooling to prevent pearlite formation. |

| Isothermal Hold | 360 °C | Maintains precise stability to engineer acicular ferrite matrix. |

| Microstructure | N/A | Secures the balance of ferrite and high-carbon austenite. |

Elevate Your Heat Treatment Precision with KINTEK

Consistency in ADI production demands unwavering thermal control. KINTEK provides the industry-leading solutions required for complex metallurgical transformations. Backed by expert R&D and manufacturing, we offer a comprehensive range of high-performance laboratory equipment, including:

- Muffle & Tube Furnaces for precise batch testing.

- Vacuum & CVD Systems for advanced material synthesis.

- Customizable High-Temp Furnaces tailored to your unique industrial needs.

Whether you are refining your quenching process or scaling up R&D, our expert-engineered systems ensure thermal uniformity and repeatability.

Ready to optimize your material performance? Contact KINTEK today to discuss your specific thermal processing requirements with our technical team.

References

- Cheng‐Hsun Hsu, Z. Chang. Improvement in Surface Hardness and Wear Resistance of ADI via Arc-Deposited CrAlSiN Multilayer Films. DOI: 10.3390/ma18092107

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of an atmosphere furnace? Control Gas Environments for Superior Material Processing

- What types of atmospheres can be created in an atmosphere protection muffle furnace? Master Material Processing with Precision

- How do atmosphere furnaces contribute to electronic material manufacturing? Unlock Precision in Semiconductor and Component Production

- What effects does a reducing atmosphere have on ceramic wares during firing? Unlock Deep Colors and Unique Finishes

- How does the heating mechanism of a retort furnace work? Unlock Precise Atmosphere Control for Your Lab

- What is the primary role of the furnace atmosphere in material processing? Control Chemical Reactions for Superior Results

- How does a horizontal box furnace facilitate atmosphere control in the synthesis of Ni-TiON catalysts?

- How is a high-temperature atmosphere furnace utilized during the internal oxidation step of Alumina Dispersion Strengthened Copper (ADSC) production? Unlock Superior Material Strength