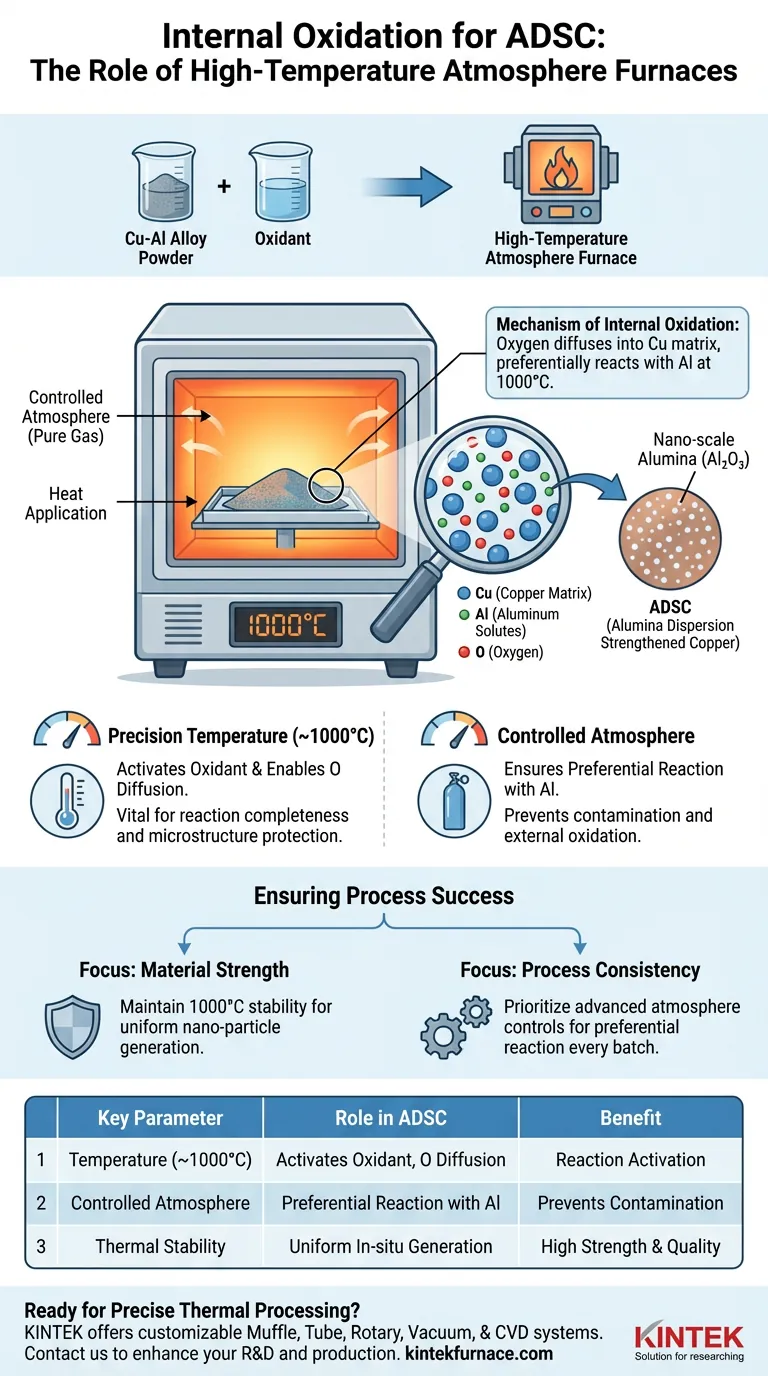

A high-temperature atmosphere furnace functions as the critical reaction vessel during the internal oxidation step, maintaining a precisely controlled environment at approximately 1000°C to trigger the necessary chemical changes within the material. By heating a mixture of Cu-Al alloy powder and an oxidant, the furnace facilitates the in-situ generation of nano-scale alumina particles, which are essential for strengthening the copper.

By sustaining a temperature of 1000°C, the furnace enables oxygen to diffuse into the copper matrix and react preferentially with aluminum. This controlled thermal process creates the dispersion strengthening phase required for high-performance Alumina Dispersion Strengthened Copper (ADSC).

The Role of Thermal Precision

Establishing the Reaction Environment

The primary utility of the furnace is to provide a stable, high-heat environment.

The process typically requires a set point of roughly 1000°C.

This specific temperature is not arbitrary; it is the thermal threshold required to activate the oxidant within the mixed powder.

Facilitating Oxygen Diffusion

At this elevated temperature, the kinetic energy of the atoms increases significantly.

This allows oxygen released by the oxidant to physically diffuse into the copper matrix.

Without this precise thermal application, the oxygen would not penetrate the alloy effectively to reach the aluminum solutes.

The Mechanism of Internal Oxidation

Preferential Reaction

The furnace environment ensures that the chemical reaction is selective.

Once the oxygen diffuses into the copper, it preferentially reacts with the aluminum present in the alloy.

This selectivity is vital, as the goal is to oxidize the aluminum without compromising the copper matrix itself.

Generating the Strengthening Phase

The product of this reaction is the formation of alumina (aluminum oxide).

Because the reaction occurs internally and at a controlled rate, these alumina particles form at the nano-scale.

These in-situ generated particles act as barriers to dislocation movement, providing the "dispersion strengthening" characteristic of the final ADSC material.

Understanding Process Constraints

The Necessity of Atmosphere Control

While heat is the primary driver, the "atmosphere" aspect of the furnace is equally critical.

The environment must be strictly controlled to prevent unwanted external oxidation or contamination.

A lack of precision here can lead to inconsistent particle distribution or surface defects in the copper powder.

Temperature Sensitivity

The process relies on a specific thermodynamic balance found around 1000°C.

Deviating significantly from this temperature can alter the diffusion rates of oxygen.

Too low, and the reaction may be incomplete; too high, and the microstructure of the copper matrix may degrade before the strengthening phase is fully established.

Ensuring Process Success

To maximize the quality of Alumina Dispersion Strengthened Copper, focus on the capabilities of the furnace regarding thermal stability and atmospheric integrity.

- If your primary focus is Material Strength: Ensure the furnace can maintain the 1000°C setpoint with minimal fluctuation to guarantee uniform nano-particle generation.

- If your primary focus is Process Consistency: Prioritize equipment with advanced atmosphere controls to ensure the oxidant reacts preferentially with aluminum in every batch.

The effectiveness of the internal oxidation step is entirely dependent on the furnace's ability to maintain the precise conditions required for in-situ alumina formation.

Summary Table:

| Key Furnace Parameter | Role in ADSC Production |

|---|---|

| Temperature (~1000°C) | Activates oxidant, enables oxygen diffusion into the copper matrix. |

| Controlled Atmosphere | Ensures preferential reaction with aluminum, prevents contamination. |

| Thermal Stability | Guarantees uniform in-situ generation of nano-scale alumina particles. |

Ready to achieve precise thermal processing for your advanced materials?

The internal oxidation step is critical for developing high-performance materials like Alumina Dispersion Strengthened Copper (ADSC). Success hinges on a furnace capable of exact temperature control and a pure atmosphere.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique high-temperature processing needs. Our furnaces are engineered for the stability and precision required to ensure consistent, high-quality results in every batch.

Contact us today to discuss how our high-temperature solutions can enhance your R&D and production. Get in touch via our contact form

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the thermal insulation properties of argon in furnace applications? Unlock Material Purity and Efficiency

- How do chemically active metals behave when heated in an air furnace? Understand the risks and solutions.

- What are the advantages of using industrial-grade plasma nitriding furnaces? Boost Stainless Steel Surface Hardness

- Why is a high-purity argon protection system required for CP-Ti? Protect Ductility in Titanium Heat Treatment

- Why is a cylindrical atmosphere furnace utilized for the salt removal process in porous stainless steel fabrication?

- What types of industries commonly use box-type atmosphere furnaces? Essential for Metallurgy, Electronics, and More

- What is the structure of a retort furnace? Unlock Precision Heat Treatment with Sealed Chamber Design

- How does the furnace atmosphere impact the final properties of a material? Master Material Engineering with Controlled Atmospheres