In furnace applications, argon provides superior thermal insulation compared to air, but this is a secondary benefit. Its primary and most critical role is to create a chemically inert atmosphere. This non-reactive environment is essential for preventing oxidation and contamination of materials during high-temperature processes, thereby preserving their quality and structural integrity.

While argon does reduce heat loss, its true value in a furnace is not as an insulator but as a protective shield. Focusing only on its thermal properties misses its most vital function: ensuring material purity in a chemically hostile, high-temperature environment.

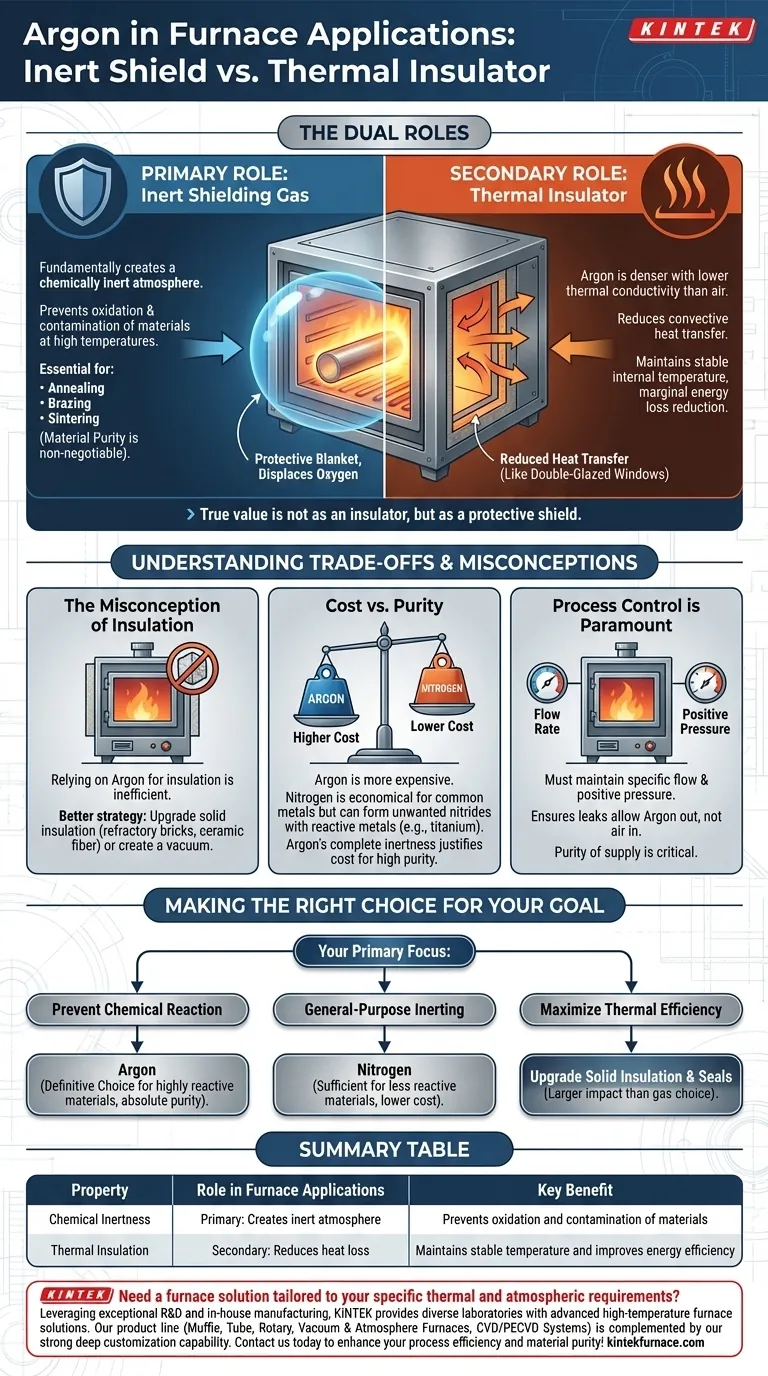

The Dual Roles of Argon in Furnaces

To understand argon's utility, you must distinguish between its primary purpose and its secondary benefits. Both stem from its fundamental properties as a noble gas.

As a Thermal Insulator (The Secondary Benefit)

Argon is denser and has lower thermal conductivity than air. This means its molecules move more slowly and transfer heat less effectively.

By filling a furnace chamber with argon instead of air, you reduce convective heat transfer. This helps maintain a more stable internal temperature and can lead to marginal reductions in energy loss to the surroundings. The principle is the same as its use in double-glazed windows, where it slows the movement of heat between the panes.

As an Inert Shielding Gas (The Primary Purpose)

This is the fundamental reason argon is used in high-temperature applications. As a noble gas, argon is chemically inert, meaning it does not react with other elements.

At the extreme temperatures inside a furnace, materials like metal become highly reactive with oxygen in the air. This reaction, known as oxidation, can ruin the surface finish, compromise the material's mechanical properties, and introduce impurities.

By displacing oxygen and other reactive gases, argon creates a protective blanket around the workpiece. This is essential for processes like annealing, brazing, and sintering, where material purity is non-negotiable.

Understanding the Trade-offs and Misconceptions

Choosing argon is a technical decision with clear consequences. It is not always the default choice, and its benefits must be weighed against practical considerations.

The Misconception of Insulation

If your only goal were to improve a furnace's thermal insulation, relying on argon would be an inefficient and expensive strategy.

Improving the furnace's solid insulation—such as refractory bricks or ceramic fiber blankets—or creating a vacuum provides a far greater impact on reducing heat loss. The choice of gas is almost always dictated by chemical compatibility with the process material, not by its insulating value.

Cost vs. Purity

Argon is significantly more expensive than nitrogen, another gas sometimes used to create a semi-inert atmosphere.

For many common metals, nitrogen is a perfectly adequate and more economical choice. However, for highly reactive metals like titanium or certain specialty steels, nitrogen can react at high temperatures to form unwanted nitrides. In these cases, argon's complete inertness justifies its higher cost.

Process Control is Paramount

Simply filling a furnace with argon is not enough. To be effective, you must maintain a specific flow rate and positive pressure.

This ensures that any leaks in the furnace seals allow argon to flow out, rather than allowing oxygen-rich air to seep in and contaminate the environment. The purity of the argon supply itself is also a critical factor.

Making the Right Choice for Your Goal

The correct atmospheric choice depends entirely on the material you are processing and your desired outcome.

- If your primary focus is preventing any chemical reaction with the workpiece: Argon is the definitive choice for protecting highly reactive materials or when absolute purity and a pristine surface finish are required.

- If your primary focus is general-purpose inerting for less reactive materials: Nitrogen often provides a sufficient protective atmosphere at a lower operational cost.

- If your primary focus is maximizing thermal efficiency: Your efforts are best spent upgrading the furnace's solid insulation and seals, as this will have a much larger impact than your choice of atmosphere gas.

Ultimately, you select a furnace atmosphere based on the chemical needs of your process, with its thermal properties being a minor, secondary consideration.

Summary Table:

| Property | Role in Furnace Applications | Key Benefit |

|---|---|---|

| Chemical Inertness | Primary: Creates inert atmosphere | Prevents oxidation and contamination of materials |

| Thermal Insulation | Secondary: Reduces heat loss | Maintains stable temperature and improves energy efficiency |

Need a furnace solution tailored to your specific thermal and atmospheric requirements? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental needs. Contact us today to enhance your process efficiency and material purity!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.