At their core, box-type atmosphere furnaces are essential tools across a surprisingly diverse range of high-tech industries. The most common users are found in metallurgy, electronics, ceramics manufacturing, and materials science research. These fields all rely on the furnace's unique ability to create a precisely controlled, high-temperature environment that is free of reactive gases like oxygen.

The unifying requirement across all these industries is not just heat, but the absolute control of the chemical environment at high temperatures. This control is what allows manufacturers and researchers to fundamentally alter and perfect a material's properties, from its hardness to its electrical conductivity.

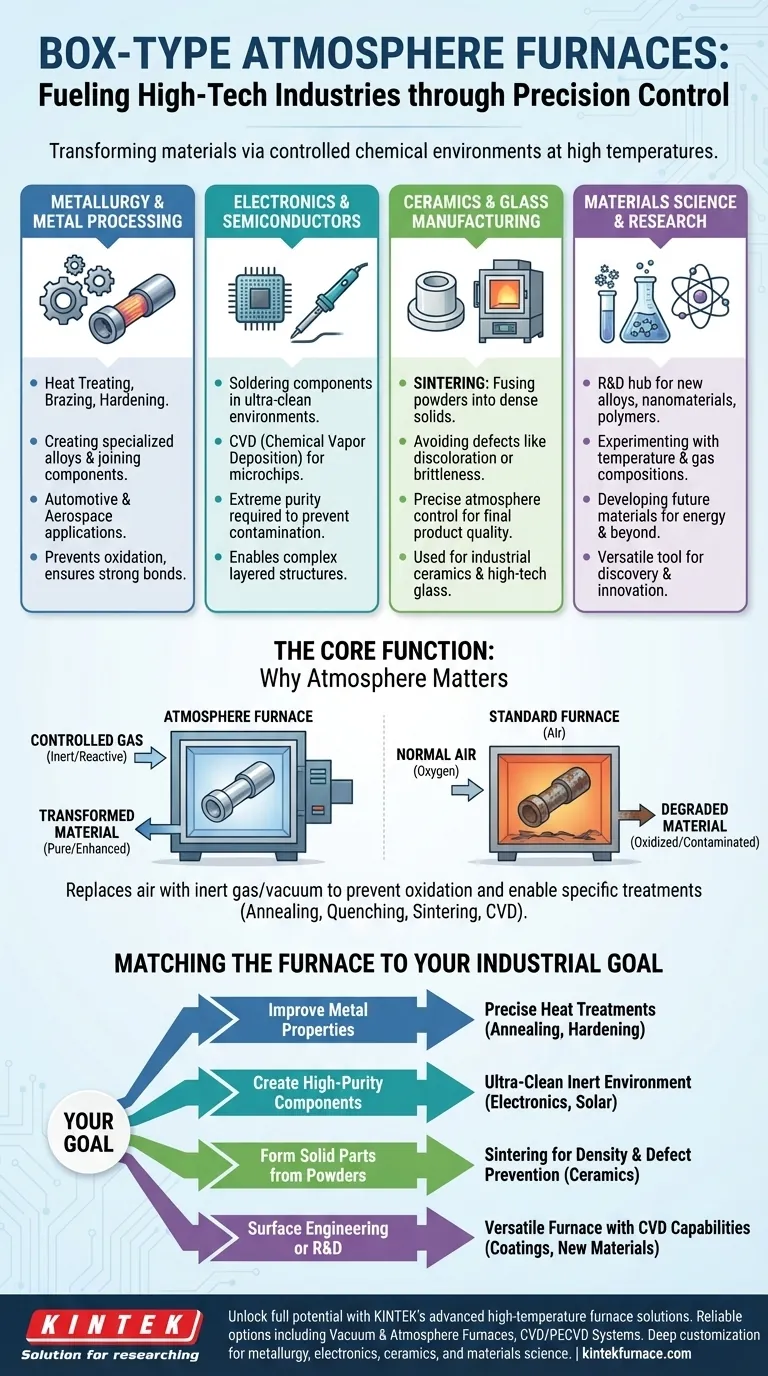

The Core Function: Why Atmosphere Control is Critical

A standard furnace heats things up. An atmosphere furnace transforms them. The "atmosphere" is a carefully chosen gas or vacuum that replaces normal air, preventing unwanted chemical reactions and enabling desired ones.

Preventing Oxidation and Contamination

At high temperatures, most materials—especially metals—will rapidly react with oxygen in the air. This process, oxidation (or rust), degrades material quality and performance.

An atmosphere furnace purges the air and replaces it with an inert gas like nitrogen or argon. This creates a clean, non-reactive environment, ensuring the material remains pure throughout the heating process.

Enabling Specific Material Treatments

The controlled atmosphere is crucial for a variety of heat treatments that define a material's final characteristics.

Key processes include annealing (softening a metal to make it more workable), quenching (rapidly cooling to harden it), sintering (fusing powders into a solid mass), and brazing (joining two pieces of metal with a filler material).

Creating New Surfaces and Films

In more advanced applications, reactive gases are intentionally introduced to alter a material's surface. A prime example is Chemical Vapor Deposition (CVD), a process used in the semiconductor and aerospace industries.

In a CVD furnace, specific gases react and deposit a thin, high-performance film or coating onto a substrate, creating everything from microchips to wear-resistant coatings on tools.

A Look Across Key Industries and Applications

The fundamental need for atmospheric control manifests in different ways across various sectors. Each industry leverages these furnaces to solve specific, high-stakes challenges.

Metallurgy and Metal Processing

This is a foundational user. Furnaces are used for heat-treating steel parts, creating specialized alloys, and joining components in the automotive and aerospace industries.

Applications like the brazing of aluminum parts or the hardening of high-speed steel tools are impossible without precise atmospheric control to prevent oxidation and ensure strong, reliable bonds.

Electronics and Semiconductors

The manufacturing of electronic components demands extreme purity. Even microscopic contamination can ruin a batch of semiconductor wafers or display devices.

Atmosphere furnaces provide the ultra-clean environments needed for processes like soldering components and, critically, for creating the complex layered structures of microchips through CVD.

Ceramics and Glass Manufacturing

For ceramics, the key process is sintering. This involves heating compacted powders to just below their melting point, causing the particles to fuse into a dense, solid object.

Controlling the atmosphere prevents unwanted reactions that could cause discoloration, brittleness, or other defects in the final ceramic product.

Materials Science and Research

Academic and research institutions are hubs of innovation, and box atmosphere furnaces are a workhorse tool. They are used to develop and test new alloys, nanomaterials, polymers, and new energy materials.

The furnace's versatility allows researchers to experiment with different materials, temperature cycles, and atmospheric compositions to discover the materials of the future.

Understanding the Trade-offs

While powerful, these furnaces are specialized equipment. Understanding their limitations is key to using them effectively.

Atmosphere vs. Vacuum

A vacuum furnace, which removes nearly all gas, offers the ultimate clean environment. However, they are often more complex and expensive.

An atmosphere furnace provides more flexibility, allowing for the use of various inert or reactive gases to achieve specific chemical outcomes that are not possible in a vacuum.

Process Specificity

The term "box-type atmosphere furnace" is a general category. Many industries use highly specialized versions tailored for a single task.

A furnace designed for general annealing of steel parts is very different from a CVD furnace designed for creating optical films, even if they share the same basic principles.

Cost and Complexity

These are not simple ovens. Atmosphere furnaces are sophisticated instruments that require significant investment, skilled operation, and careful maintenance to manage gas flows and ensure safety.

Matching the Furnace to the Industrial Goal

Choosing and using an atmosphere furnace depends entirely on the desired outcome for your material.

- If your primary focus is improving metal properties: You need a furnace for precise heat treatments like annealing, quenching, or brazing to achieve specific hardness and durability targets.

- If your primary focus is creating high-purity components: You require an ultra-clean, inert gas environment for applications in electronics, solar cells, or semiconductor manufacturing.

- If your primary focus is forming solid parts from powders: You will use a furnace for sintering ceramics or metals, where precise atmosphere control is critical for preventing defects and achieving desired density.

- If your primary focus is surface engineering or R&D: You need a versatile furnace, potentially with CVD capabilities, to create specialized coatings or experiment with novel material compositions.

Ultimately, mastering the furnace's controlled environment is the key to mastering the final performance of the material itself.

Summary Table:

| Industry | Key Applications | Key Benefits |

|---|---|---|

| Metallurgy | Annealing, brazing, hardening | Prevents oxidation, enhances material strength |

| Electronics | Soldering, CVD for microchips | Ensures ultra-clean environments, prevents contamination |

| Ceramics | Sintering | Avoids defects, improves density and durability |

| Materials Science | R&D on alloys, nanomaterials | Enables experimentation with atmospheres for innovation |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs in metallurgy, electronics, ceramics, and materials science. Contact us today to discuss how we can enhance your processes and drive innovation!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance