At their core, atmosphere furnaces are essential precision instruments used to create and modify electronic materials in highly controlled environments. They perform critical processes such as growing semiconductor crystals, doping wafers, annealing to repair material defects, depositing thin films, and packaging integrated circuits, all of which are impossible to achieve reliably in open air.

The fundamental value of an atmosphere furnace is not just its ability to heat, but its power to precisely control the chemical environment. This control is the deciding factor in achieving the material purity and structural perfection required for high-performance electronic components.

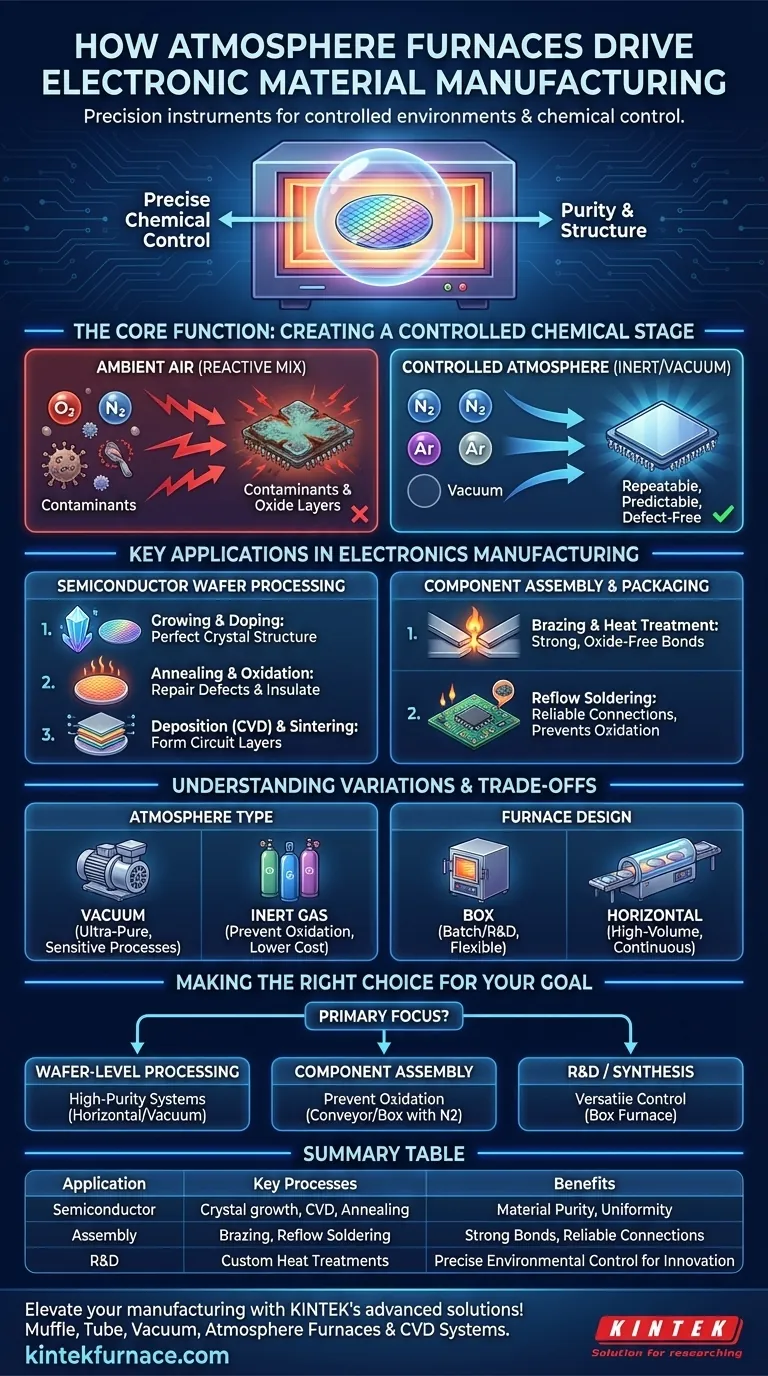

The Core Function: Creating a Controlled Chemical Stage

What Is an Atmosphere Furnace?

An atmosphere furnace is a high-temperature chamber where the surrounding gas is strictly controlled. Instead of heating materials in ambient air—which is a reactive mix of nitrogen, oxygen, and other elements—it replaces the air with a specific, controlled "atmosphere."

This atmosphere can be an inert gas like nitrogen or argon, a reactive gas for a specific purpose, or even a vacuum to remove all gases entirely. This control transforms the furnace from a simple oven into a precise chemical reactor.

Why This Control Is Non-Negotiable

At the microscopic level, manufacturing electronic materials is a process of controlled chemistry. Unwanted elements, especially oxygen, act as contaminants.

Oxygen can react with semiconductor materials, create unintended oxide layers, and prevent a clean bond during soldering or brazing. By removing or replacing the air, an atmosphere furnace eliminates these variables, ensuring the process is repeatable, predictable, and free from defects.

Key Applications in Electronics Manufacturing

Semiconductor Wafer Processing

Growing and Doping: For a semiconductor to function, its crystal structure must be near-perfect and it must be "doped" with a precise number of impurity atoms. Atmosphere furnaces provide the stable, high-purity environment needed to grow large, single-crystal ingots and to diffuse dopants evenly into wafers.

Annealing and Oxidation: High-temperature processing can create stress and defects in a material's crystal lattice. Annealing is a heat treatment process in a controlled atmosphere that repairs this damage, improving electrical performance. Conversely, controlled oxidation is used intentionally to grow ultra-pure, uniform layers of silicon dioxide (SiO2), a critical insulator in virtually all modern chips.

Deposition and Sintering: Atmosphere furnaces are used for Chemical Vapor Deposition (CVD), where gases react on the wafer surface to deposit thin films that form the circuit's layers. They are also used for sintering, a process that uses heat to fuse powdered materials into a solid, dense component without melting them.

Component Assembly and Packaging

Brazing and Heat Treatment: Many electronic components require joining dissimilar materials. Brazing in an inert atmosphere uses a filler metal to create a strong joint without oxidizing and weakening the metal surfaces. General heat treatments are also used to enhance the strength and durability of metal leads and casings.

Reflow Soldering: During the assembly of a circuit board, a controlled nitrogen atmosphere prevents the microscopic solder pads and component leads from oxidizing. This ensures the molten solder can "wet" and bond cleanly to the surfaces, creating reliable electrical connections and preventing faulty joints.

Understanding the Variations and Trade-offs

Vacuum vs. Inert Gas Atmosphere

A vacuum furnace is an extreme type of atmosphere furnace that removes nearly all gas molecules, creating an ultra-pure environment ideal for sensitive processes like wafer diffusion.

An inert gas furnace (using nitrogen or argon) is more common for processes like reflow soldering or brazing, where the primary goal is simply to prevent oxidation. It offers excellent protection at a lower operational cost than a high-vacuum system.

Box vs. Horizontal Furnaces

This distinction relates to the physical design and process flow. Box furnaces are typically used for batch processing, R&D, or thermal analysis where flexibility is key.

Horizontal furnaces are tube-shaped and are often used in high-volume semiconductor fabrication lines, allowing for the continuous processing of many wafers with excellent uniformity. The choice depends on production scale, not a fundamental difference in the need for atmospheric control.

Making the Right Choice for Your Goal

Selecting the right furnace technology comes down to the specific manufacturing objective and the level of purity required.

- If your primary focus is wafer-level semiconductor processing (diffusion, oxidation): You need high-purity systems like horizontal tube furnaces capable of maintaining vacuum or a specific process gas.

- If your primary focus is component assembly (soldering, brazing): You need a furnace that reliably prevents oxidation, where a nitrogen-atmosphere conveyor or box furnace is often the most cost-effective solution.

- If your primary focus is R&D or synthesizing novel materials: You need a versatile system, often a box furnace, that allows for precise control over a wide range of temperatures and gas mixtures.

Ultimately, mastering the atmospheric conditions inside the furnace is fundamental to mastering the production of modern electronic materials.

Summary Table:

| Application | Key Processes | Benefits |

|---|---|---|

| Semiconductor Wafer Processing | Crystal growth, doping, annealing, CVD | Ensures material purity, uniform doping, defect repair |

| Component Assembly | Brazing, reflow soldering, heat treatment | Prevents oxidation, ensures strong bonds, reliable connections |

| R&D and Material Synthesis | Custom heat treatments, gas mixtures | Supports innovation with precise environmental control |

Elevate your electronic material manufacturing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether for semiconductor processing, component assembly, or innovative R&D. Contact us today to discuss how our expertise can enhance your production efficiency and material quality!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments