At its core, an inert atmosphere furnace works by systematically replacing the reactive air inside a sealed chamber with a non-reactive gas, typically nitrogen or argon. This process creates a controlled, chemically inactive environment that shields the material from oxygen and moisture during high-temperature heating, thereby preventing oxidation and other unwanted chemical reactions.

The primary function of an inert atmosphere furnace is not just to heat a material, but to actively protect it. It creates a chemically neutral shield, ensuring that the properties of the material are altered only by the heat itself, not by a reaction with the air around it.

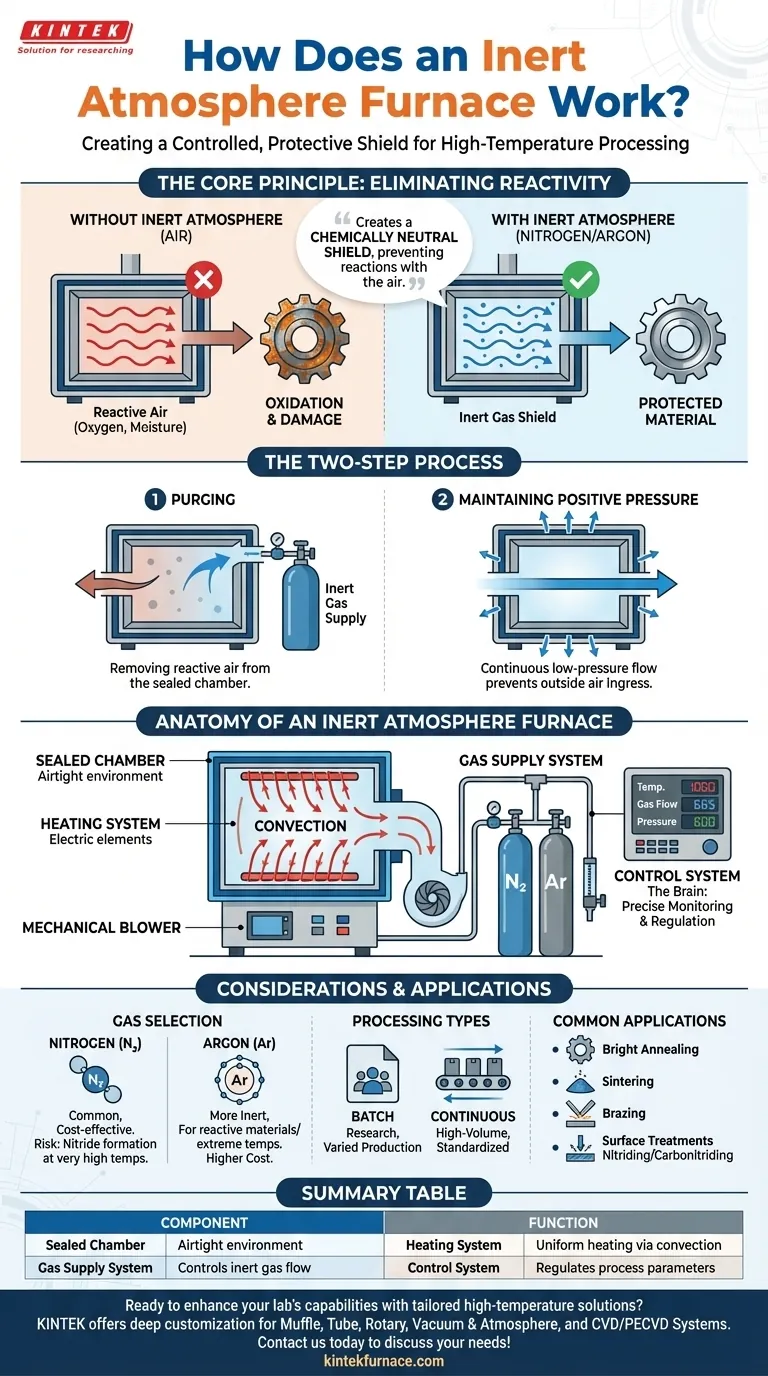

The Fundamental Principle: Eliminating Reactivity

At high temperatures, materials become significantly more vulnerable to chemical changes. An inert atmosphere furnace is designed specifically to counteract this vulnerability.

Why Air is the Enemy

The normal air we breathe is about 21% oxygen and contains variable amounts of water vapor. While harmless at room temperature, these components become highly reactive when heated.

This reactivity leads to oxidation, which can manifest as surface discoloration, scaling, or a complete change in the material's chemical composition and structural integrity.

Creating the Protective Shield

The furnace's operation is a two-step process to create and maintain a protective bubble of inert gas.

-

Purging: First, the air must be removed from the sealed chamber. This is often done by pumping in the inert gas to displace the lighter air. For more sensitive applications, a vacuum may be pulled first to evacuate the majority of the air before backfilling the chamber with the inert gas.

-

Maintaining Positive Pressure: A continuous, low-pressure flow of the inert gas is maintained throughout the heating cycle. This slight positive pressure ensures that if any microscopic leaks exist in the chamber, the inert gas will flow out rather than allowing outside air to seep in.

Anatomy of an Inert Atmosphere Furnace

Several key components work in concert to achieve this controlled environment.

The Sealed Chamber

This is the foundational component. The chamber is engineered to be airtight, preventing any contamination from the outside atmosphere once the purging process is complete.

The Gas Supply System

This system manages the flow of inert gas from storage tanks into the furnace. It includes regulators and flowmeters that allow for precise control over the volume and pressure of the gas entering the chamber.

The Heating System

Heating is typically achieved with high-power electric resistance elements. The heat is transferred to the workload primarily through convection, as the circulating inert gas carries thermal energy throughout the chamber. Mechanical blowers are often used to ensure rapid and uniform temperature distribution.

The Control System

The brain of the operation is an advanced control system. It monitors and regulates the temperature, gas flow rate, and internal pressure, ensuring the process is exact and repeatable for consistent results.

Understanding the Trade-offs and Considerations

While highly effective, using an inert atmosphere involves specific costs and technical decisions.

Cost and Complexity

The addition of a gas delivery system, a sealed chamber, and advanced controls makes these furnaces more complex and expensive than standard air-atmosphere models. The inert gas itself is a continuous operational cost.

Gas Selection: Nitrogen vs. Argon

Nitrogen is the most common choice as it is effective and relatively inexpensive. However, at very high temperatures, it can react with certain materials like titanium and some stainless steels to form unwanted nitrides.

Argon is more chemically inert than nitrogen and is used for processing highly reactive materials or at extreme temperatures. This superior performance comes at a significantly higher cost.

Batch vs. Continuous Processing

Furnaces come in two main configurations. Batch furnaces process a single workload at a time and are ideal for research, development, or varied production needs. Continuous furnaces process a steady stream of material and are used for high-volume, standardized manufacturing.

Common Applications

This technology is critical for processes where surface finish and chemical purity are paramount. Key applications include bright annealing (to prevent discoloration), sintering (fusing powdered metals), brazing, and specialized surface treatments like nitriding and carbonitriding.

Making the Right Choice for Your Goal

Selecting the right furnace setup depends entirely on your material and desired outcome.

- If your primary focus is cost-effective oxidation prevention for common steels: A nitrogen-based system is the standard for processes like bright annealing.

- If your primary focus is processing highly reactive metals like titanium or superalloys: An argon atmosphere is necessary to avoid unwanted chemical reactions, despite the higher gas cost.

- If your primary focus is high-volume, standardized production: A continuous furnace design will deliver the highest throughput and efficiency for your process.

Ultimately, an inert atmosphere furnace provides absolute control over the chemical environment, ensuring the material's integrity during critical heat treatment.

Summary Table:

| Component | Function |

|---|---|

| Sealed Chamber | Provides an airtight environment to prevent contamination |

| Gas Supply System | Controls flow of inert gases like nitrogen or argon |

| Heating System | Uses electric elements and convection for uniform temperature |

| Control System | Monitors and regulates temperature, gas flow, and pressure |

Ready to enhance your lab's capabilities with tailored high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures precise fit for your unique experimental needs—whether for bright annealing, sintering, or processing reactive materials. Contact us today to discuss how our inert atmosphere furnaces can protect your materials and boost efficiency!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance