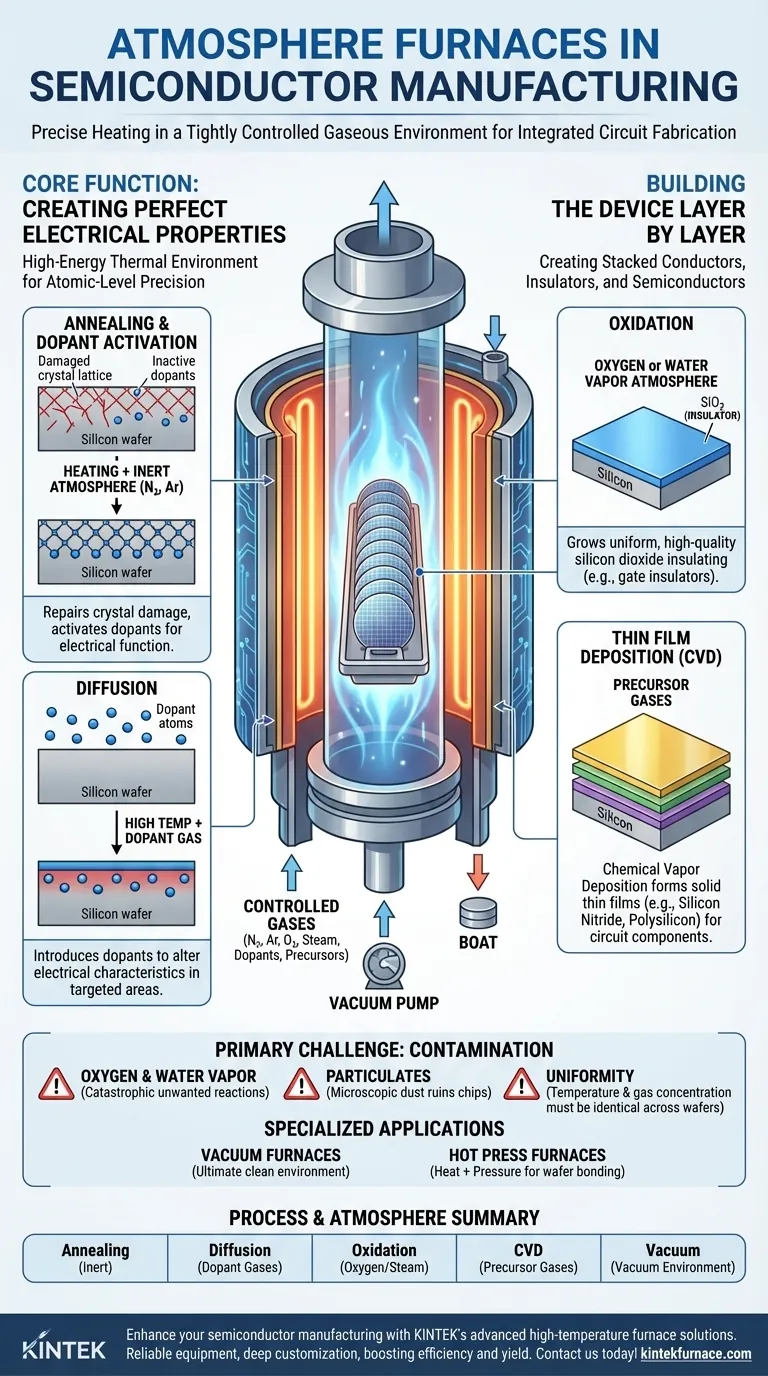

In short, atmosphere furnaces are used in semiconductor manufacturing to precisely heat silicon wafers in a tightly controlled gaseous environment. This control is essential for critical fabrication steps like annealing, diffusion, oxidation, and the deposition of thin films, which collectively form the integrated circuits on a chip.

The fundamental purpose of an atmosphere furnace is not merely to heat the wafer, but to create a specific, ultra-pure chemical environment. This prevents unwanted reactions and contamination, allowing engineers to intentionally alter the wafer's material properties with atomic-level precision.

The Core Function: Creating Perfect Electrical Properties

Semiconductor manufacturing is a process of methodically building and altering layers on a silicon wafer. Atmosphere furnaces provide the high-energy thermal environment needed to drive these changes.

Annealing and Dopant Activation

After ions (dopants) are implanted into the silicon to change its electrical conductivity, the wafer's crystal structure is damaged.

Annealing is a heating process performed in an inert atmosphere (like nitrogen or argon) to repair this crystal lattice damage. It also serves to "activate" the dopants, moving them into the correct positions within the crystal so they can function electrically.

Diffusion

Diffusion is another method for introducing dopants. Wafers are placed in a furnace, and a specific gas containing the desired dopant atoms is introduced.

At high temperatures, these atoms diffuse from the gas into the silicon wafer's surface, changing its electrical characteristics in targeted areas. The furnace's control over temperature and gas concentration dictates the final dopant profile.

Building the Device Layer by Layer

Modern chips consist of millions or billions of transistors built from stacked layers of conducting, insulating, and semiconducting materials. Furnaces are critical for creating these layers.

Oxidation

One of the most crucial layers is silicon dioxide (SiO₂), an excellent electrical insulator.

In an oxidation furnace, wafers are heated in an atmosphere of pure oxygen or water vapor. This causes a uniform, high-quality layer of SiO₂ to "grow" on the silicon surface, forming the gate insulators essential for transistor operation.

Thin Film Deposition (CVD)

Chemical Vapor Deposition (CVD) is a process used to deposit thin films of various materials onto the wafer.

Precursor gases are introduced into a CVD furnace, where they react at high temperatures on the wafer's surface to form a solid film, such as silicon nitride (an insulator) or polysilicon (a conductor). This is how the "wires" and other components of the circuit are built.

Specialized Furnace Applications

Different fabrication steps require different types of atmosphere control.

- Vacuum Furnaces create an environment almost entirely free of gas molecules. This is the ultimate clean atmosphere, used for processes like surface cleaning and heat treatments where any reaction with ambient gases must be avoided.

- Hot Press Furnaces apply both heat and mechanical pressure. They are used for tasks like wafer bonding, where two separate semiconductor wafers are physically joined together to create advanced 3D structures.

Understanding the Primary Challenge: Contamination

The extreme precision required in semiconductor fabrication means that any deviation from the intended environment is a potential source of failure. This is the central challenge that atmosphere furnaces are designed to solve.

The Enemy: Oxygen and Water Vapor

For any process not intended to be oxidation, the presence of even trace amounts of oxygen or water vapor is catastrophic. Unwanted oxidation can create unintended insulating layers, alter material properties, and cause device failure. An inert or vacuum atmosphere is the only solution.

The Risk of Particulates

Furnaces must also be flawlessly clean. A single microscopic dust particle landing on a wafer before or during a thermal process can block a deposition or etch step, creating a defect that ruins the entire chip.

The Demand for Uniformity

The temperature across a 300mm wafer (and from wafer to wafer) must be incredibly uniform. Any temperature variation can cause layers to grow at different thicknesses or dopants to diffuse unevenly, leading to inconsistent performance across the chips on the wafer.

Matching the Furnace to the Manufacturing Step

Choosing the right furnace technology is dictated entirely by the specific process step being performed.

- If your primary focus is depositing complex thin films: You will use a CVD furnace, which is optimized for precise gas flow and chemical reactions on the wafer surface.

- If your primary focus is activating dopants or repairing crystal damage: An annealing furnace providing an inert (non-reactive) gas atmosphere is the correct tool.

- If your primary focus is growing a high-quality insulating layer: An oxidation furnace is specifically designed to introduce a controlled oxygen or steam environment.

- If your primary focus is ensuring absolute purity for heat treatment: A vacuum furnace is essential for removing virtually all reactive gas molecules.

Ultimately, the precise control offered by atmosphere furnaces is what transforms a simple silicon wafer into the complex foundation of all modern electronics.

Summary Table:

| Process | Purpose | Atmosphere Used |

|---|---|---|

| Annealing | Repair crystal damage, activate dopants | Inert (e.g., nitrogen, argon) |

| Diffusion | Introduce dopants into silicon | Specific dopant gases |

| Oxidation | Grow silicon dioxide insulating layers | Oxygen or water vapor |

| CVD | Deposit thin films (e.g., silicon nitride) | Precursor gases for reactions |

| Vacuum Processing | Ensure purity, prevent contamination | Vacuum environment |

Enhance your semiconductor manufacturing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, boosting efficiency and yield. Contact us today to discuss how we can support your critical processes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas