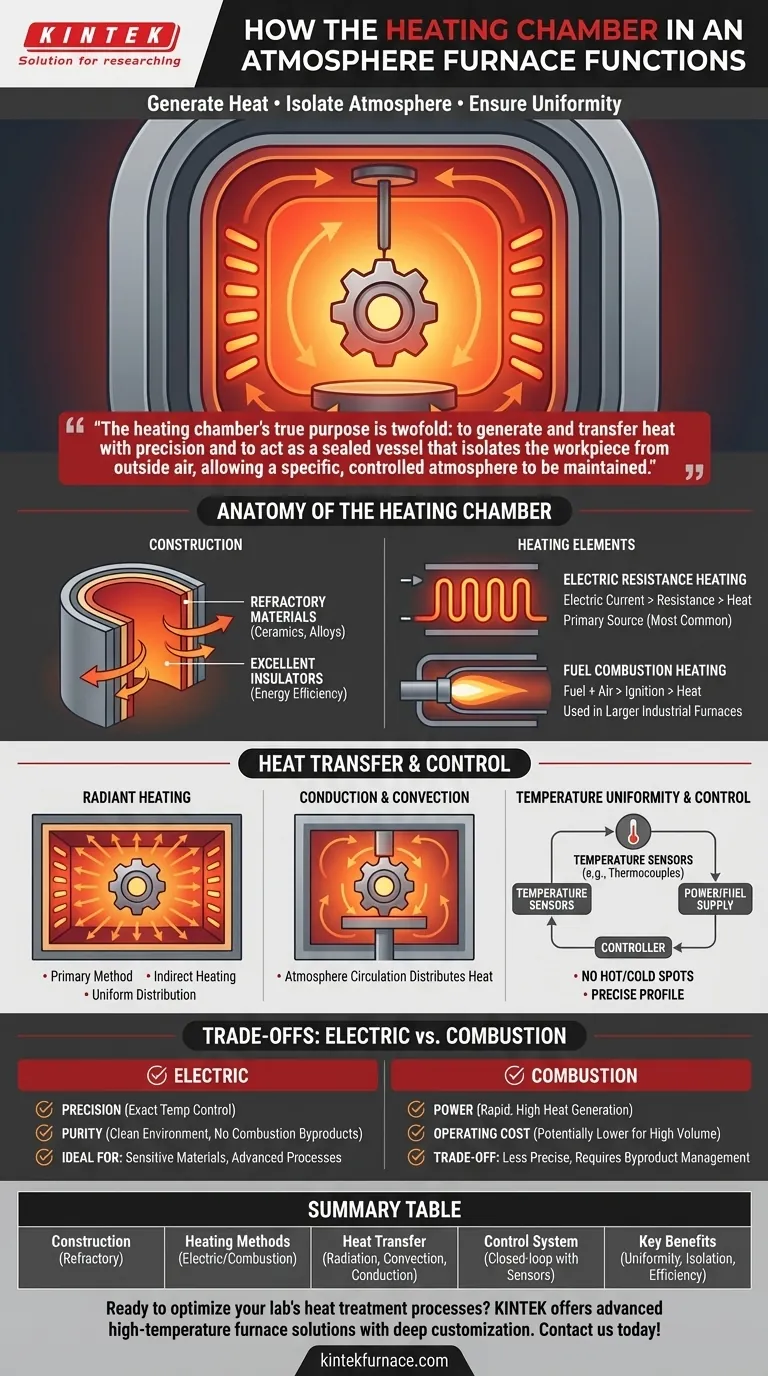

At its core, an atmosphere furnace's heating chamber functions by using a controlled energy source to generate heat, which is then transferred uniformly to a workpiece. The chamber is constructed from specialized materials that not only withstand extreme temperatures but also provide critical insulation to maintain a stable and isolated environment for the heat treatment process.

The heating chamber's true purpose is twofold: to generate and transfer heat with precision and to act as a sealed vessel that isolates the workpiece from outside air, allowing a specific, controlled atmosphere to be maintained.

The Anatomy of the Heating Chamber

The effectiveness of any atmosphere furnace begins with the design and materials of its heating chamber. This is where the foundational work of heat treatment occurs.

Construction: A High-Temperature Shell

The chamber itself is built from refractory materials, typically advanced ceramics or specialized metal alloys.

These materials are chosen for their ability to withstand constant, extreme thermal cycling without degrading. They also serve as excellent insulators, preventing heat from escaping and ensuring energy efficiency.

Heating Elements: The Engine of the Furnace

The method used to generate heat is a defining characteristic of the furnace. The two primary methods are electric resistance and fuel combustion.

Electric Resistance Heating

This is the most common method for modern atmosphere furnaces. An electrical current is passed through heating elements made of materials like Kanthal or Nichrome.

The inherent resistance of these elements causes them to heat up significantly, becoming the primary source of thermal energy within the chamber.

Fuel Combustion Heating

In some industrial applications, particularly larger tube furnaces, heat is generated by the combustion of fuel.

A precise mixture of fuel and air is ignited, creating a flame that heats the chamber. The ratio of fuel to air is also used to help regulate the furnace's internal atmosphere.

How Heat is Transferred and Controlled

Generating heat is only the first step. The chamber's design is critical for ensuring that heat is delivered to the workpiece effectively and uniformly.

The Principle of Radiant Heating

The primary method of heat transfer is radiation. The hot heating elements and insulated chamber walls radiate thermal energy in all directions.

This energy travels through the controlled atmosphere and is absorbed by the surface of the workpiece. This indirect heating method prevents direct contact with the heating elements, ensuring a cleaner process and more uniform temperature distribution.

The Role of Conduction and Convection

While radiation is dominant, conduction (heat transfer through direct contact) and convection (heat transfer through the movement of hot gases) also play a part.

The controlled atmosphere gas inside the chamber heats up and circulates, helping to distribute thermal energy to all surfaces of the workpiece.

Achieving Temperature Uniformity

A key function of the chamber is to prevent "hot spots" or "cold spots." The strategic placement of heating elements and the quality of the insulation are engineered to create a uniform thermal environment.

Closed-Loop Temperature Control

Modern furnaces use a closed-loop system for control. Temperature sensors (like thermocouples) constantly measure the chamber's internal temperature.

This data is fed to a controller, which automatically adjusts the power sent to the electric elements or the fuel supply for combustion systems. This ensures the temperature precisely follows the desired profile for the heat treatment cycle.

Understanding the Trade-offs: Electric vs. Combustion

The choice between an electric and a combustion-based heating system involves significant trade-offs that impact process control and operational cost.

Precision and Purity (Electric)

Electric resistance heating offers exceptionally precise temperature control and an inherently clean environment.

Because there are no byproducts of combustion, it is far easier to maintain the purity of the controlled atmosphere, which is critical for sensitive materials and advanced processes.

Power and Operating Cost (Combustion)

Fuel combustion can often generate very high levels of heat more rapidly and, in some industrial scenarios, at a lower operating cost than electricity.

However, this comes at the cost of less precise control. The combustion byproducts must also be carefully managed to avoid contaminating the furnace atmosphere and the workpiece.

Making the Right Choice for Your Goal

Your process requirements will determine which type of heating system is most appropriate.

- If your primary focus is process purity and precise temperature control: An electrically heated furnace is the superior choice for its cleanliness and responsiveness.

- If your primary focus is high-volume throughput where raw heating power is paramount: A fuel combustion furnace may be a more practical and cost-effective solution.

Understanding how the heating chamber generates, transfers, and controls thermal energy empowers you to select the right tool and optimize your process for consistent, high-quality results.

Summary Table:

| Aspect | Details |

|---|---|

| Construction | Refractory materials (ceramics, alloys) for insulation and durability |

| Heating Methods | Electric resistance (precise, clean) or fuel combustion (powerful, cost-effective) |

| Heat Transfer | Primarily radiation, with conduction and convection for uniformity |

| Control System | Closed-loop with temperature sensors for stable thermal profiles |

| Key Benefits | Uniform heating, atmosphere isolation, energy efficiency, and process control |

Ready to optimize your lab's heat treatment processes? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our expertise can enhance your efficiency and results!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening