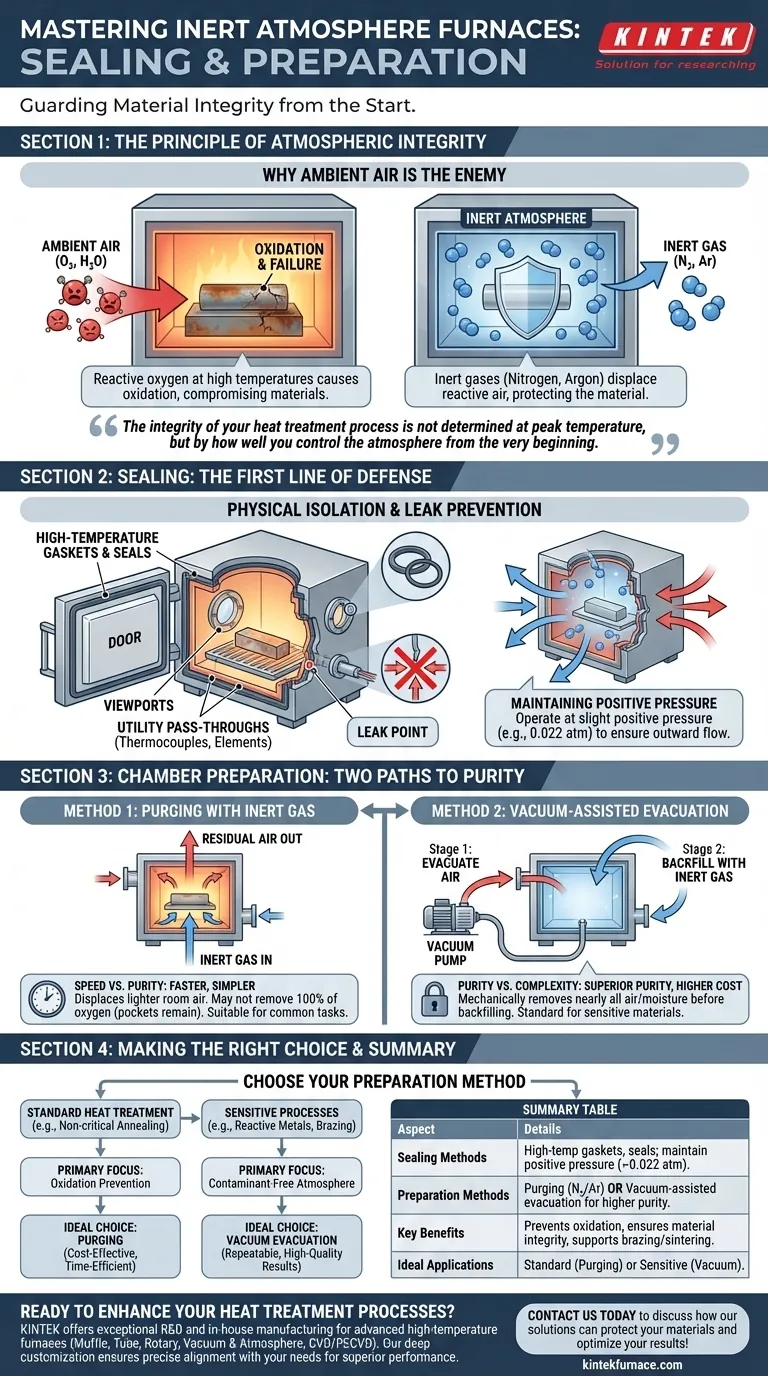

To properly prepare an inert atmosphere furnace, you must first ensure every potential leak point—including doors, element connections, and thermocouple ports—is secured with high-temperature seals and gaskets. Once the chamber is mechanically sealed, the ambient room air is removed and replaced with an inert gas like nitrogen or argon, either by purging the chamber with a continuous gas flow or by using a vacuum pump to evacuate the air before backfilling with the process gas.

The integrity of your heat treatment process is not determined at peak temperature, but by how well you control the atmosphere from the very beginning. A failure in sealing or gas preparation directly translates to material oxidation, compromised results, and process inconsistency.

The Principle of Atmospheric Integrity

The core purpose of an inert atmosphere furnace is to create a chemically non-reactive environment during high-temperature processing. This controlled environment is essential for preventing unwanted chemical reactions, primarily oxidation.

Why Ambient Air Is the Enemy

At elevated temperatures, materials become highly susceptible to oxidation when exposed to the oxygen in ambient air. This can lead to surface discoloration, compromised structural integrity, and the complete failure of processes like brazing or sintering.

The Role of Inert Gas

Inert gases, most commonly nitrogen and argon, act as a stable medium that will not react with the workpiece, even at extreme temperatures. They displace the reactive oxygen, effectively protecting the material throughout the heating and cooling cycle.

Sealing: The First Line of Defense

Before you can control the atmosphere, you must physically isolate it. This is the primary function of the furnace's seals.

High-Temperature Gaskets and Seals

Every opening is a potential failure point. Doors, viewports, and utility pass-throughs for thermocouples and heating elements must be fitted with specialized gaskets designed to withstand high temperatures and prevent gas exchange.

Maintaining Positive Pressure

A perfectly airtight seal is difficult to achieve. Therefore, furnaces are typically operated at a slight positive pressure (e.g., up to 0.022 atmospheres). This ensures that if any microscopic leak exists, the inert gas will flow out of the chamber, preventing ambient air from flowing in.

Chamber Preparation: Two Paths to Purity

Once the furnace is sealed, the residual room air inside the chamber must be removed. This is achieved through one of two primary methods.

Method 1: Purging with Inert Gas

This is the most direct method. Inert gas is introduced through an inlet port, and it physically displaces the lighter room air, which exits through an outlet port. The chamber is "purged" for a sufficient duration to ensure the oxygen concentration has dropped to an acceptable level.

Method 2: Vacuum-Assisted Evacuation

For applications requiring the highest purity, a vacuum pump is used to mechanically remove nearly all the air and moisture from the sealed chamber. Once a sufficient vacuum is achieved, the chamber is backfilled with high-purity inert gas. This process can be repeated in cycles for maximum effectiveness.

Understanding the Trade-offs

The choice between purging and vacuum evacuation is a decision based on process requirements, material sensitivity, and equipment cost.

Purging: Speed vs. Purity

Purging is faster, simpler, and requires less complex equipment. However, it may not remove 100% of the oxygen, as pockets of air can become trapped. This makes it suitable for many common heat-treating tasks but potentially risky for highly sensitive materials.

Vacuum Evacuation: Purity vs. Complexity

Using a vacuum offers superior atmospheric purity and is the standard for processing reactive metals or performing critical brazing operations. The trade-off is increased cycle time, higher equipment cost, and the added complexity of maintaining a vacuum system.

Making the Right Choice for Your Goal

Your preparation method should align directly with the sensitivity of your process.

- If your primary focus is standard heat treatment (e.g., non-critical annealing): Simple purging is often sufficient, providing a cost-effective and time-efficient solution for oxidation prevention.

- If your primary focus is working with highly reactive materials or sensitive processes (e.g., brazing, medical implants): Vacuum-assisted evacuation is the definitive choice to guarantee a contaminant-free atmosphere and ensure repeatable, high-quality results.

Ultimately, mastering furnace preparation is about controlling the invisible environment to guarantee visible success in your work.

Summary Table:

| Aspect | Details |

|---|---|

| Sealing Methods | Use high-temperature gaskets and seals on doors, ports; maintain positive pressure up to 0.022 atm to prevent air ingress. |

| Preparation Methods | Purging with inert gas (nitrogen/argon) or vacuum-assisted evacuation for higher purity. |

| Key Benefits | Prevents oxidation, ensures material integrity, and supports processes like brazing and sintering. |

| Ideal Applications | Standard heat treatment (purging) or sensitive processes like reactive metals (vacuum). |

Ready to enhance your laboratory's heat treatment processes with reliable inert atmosphere solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior performance and consistency. Contact us today to discuss how our solutions can protect your materials and optimize your results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage