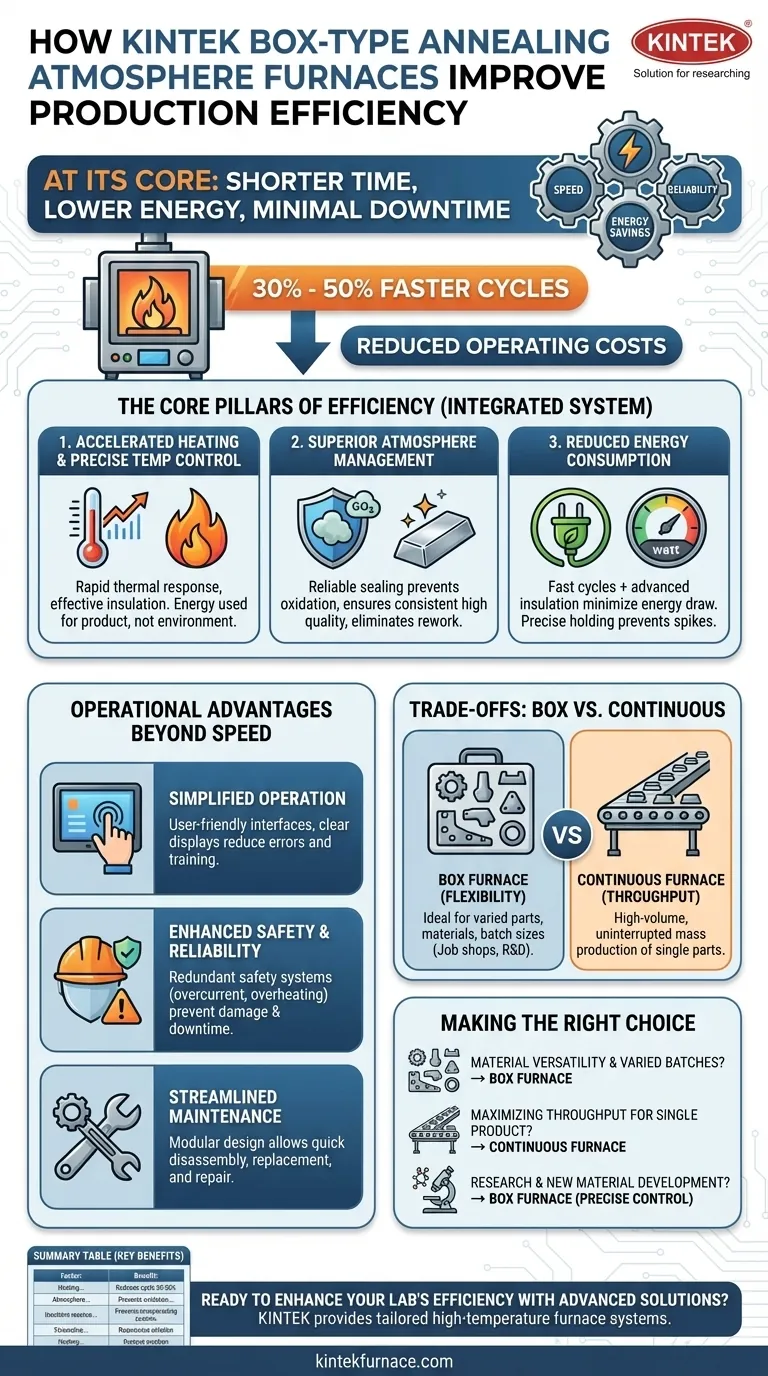

At its core, a box-type annealing atmosphere furnace improves production efficiency by fundamentally shortening process time, reducing energy consumption, and minimizing operational downtime. This is achieved through rapid heating capabilities and precise temperature control, which can shorten the required annealing cycle by 30% to 50% compared to traditional furnace designs.

The true advantage of this furnace is not just speed, but a synthesis of thermal precision, atmospheric control, and operational reliability. This combination leads to faster throughput, higher quality parts, and lower overall operating costs.

The Core Pillars of Efficiency

A box-type furnace's efficiency gains are not from a single feature, but from an integrated system design. Each component works to reduce waste, whether in time, energy, or material.

Accelerated Heating and Precise Temperature Control

The most direct impact on efficiency is the reduction of the heat treatment cycle. The furnace's design allows it to reach and maintain target temperatures very quickly.

This rapid thermal response, combined with highly effective insulation, ensures that energy is used to heat the product, not the surrounding environment. This shortens cycle times and directly lowers energy bills.

Superior Atmosphere Management

Annealing often requires a specific, controlled atmosphere to prevent oxidation and ensure desired material properties. Inefficient systems lead to material loss or rework.

These furnaces feature reliable sealing structures and precise atmosphere control. This prevents leaks and maintains the exact gas composition needed, resulting in higher-quality, consistent output and eliminating the need for costly secondary cleaning operations.

Reduced Energy Consumption

Energy is a primary operational cost in heat treatment. Efficiency here is a significant financial lever.

By combining fast heating cycles with advanced insulation, the furnace minimizes its energy draw per cycle. The ability to precisely hold a temperature without significant fluctuation further prevents wasteful energy spikes.

Operational Advantages Beyond Speed

True production efficiency also accounts for usability, safety, and maintenance. A furnace that is difficult to run or frequently down for repair is inefficient, regardless of its cycle time.

Simplified Operation and Monitoring

Complex controls can lead to operator error, inconsistent results, and extended training periods. Modern box furnaces address this with user-friendly interfaces.

Clear digital displays allow for easy parameter setting and process monitoring. This reduces the chance of mistakes and makes the equipment accessible to a wider range of technical staff.

Enhanced Safety and Reliability

Unplanned downtime from equipment failure or a safety incident is devastating to production schedules. Reliability is a cornerstone of efficiency.

These furnaces are built with multiple, redundant safety systems. Features like overcurrent, overheating, and leakage protection automatically shut down the system and alert operators to prevent damage and ensure a safe working environment.

Streamlined Maintenance and Reduced Downtime

When maintenance is required, speed is essential. The modular design of many box-type furnaces is a key advantage.

Components are designed for quick disassembly, replacement, and repair. This design philosophy significantly reduces the time the furnace is out of commission, maximizing its availability for production.

Understanding the Trade-offs: Box vs. Continuous

While highly efficient, the box-type furnace is not the universal solution. Its batch-based nature creates a critical distinction from continuous furnace systems.

Flexibility for Varied Production

The box furnace excels in environments that require flexibility. It is ideal for processing different parts, materials, or batch sizes throughout the day.

This makes it perfectly suited for job shops, research and development, or manufacturing lines with diverse product mixes, including advanced materials like titanium alloys and high-temperature alloys.

Throughput for Mass Production

In contrast, a continuous furnace is designed for high-volume, uninterrupted mass production of a single, consistent part.

While a continuous furnace offers higher throughput for a dedicated product line, it lacks the flexibility of a box furnace. The choice depends entirely on the production environment.

Making the Right Choice for Your Goal

Selecting the correct furnace requires a clear understanding of your specific production needs and operational priorities.

- If your primary focus is material versatility and varied batch sizes: The box-type furnace's precise control and batch-based flexibility is the superior choice.

- If your primary focus is maximizing throughput for a single, high-volume product: A continuous furnace will provide greater overall efficiency for that dedicated task.

- If your primary focus is research and new material development: The box-type furnace's precise, repeatable control over both temperature and atmosphere is essential.

Ultimately, choosing the right equipment is about aligning the technology's strengths with your strategic operational goals.

Summary Table:

| Efficiency Factor | Key Benefit |

|---|---|

| Heating and Temperature Control | Reduces cycle time by 30-50% with rapid heating and precise control |

| Atmosphere Management | Prevents oxidation, ensures high-quality output, and eliminates rework |

| Energy Consumption | Lowers energy use through fast cycles and advanced insulation |

| Operational Simplicity | User-friendly interfaces reduce errors and training time |

| Safety and Reliability | Built-in safety systems minimize downtime and ensure safe operation |

| Maintenance | Modular design allows quick repairs, reducing operational downtime |

Ready to enhance your lab's efficiency with advanced furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace systems. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our box-type annealing atmosphere furnaces can boost your production efficiency and reduce costs!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity